Understanding DC Motor Types: Complete Guide

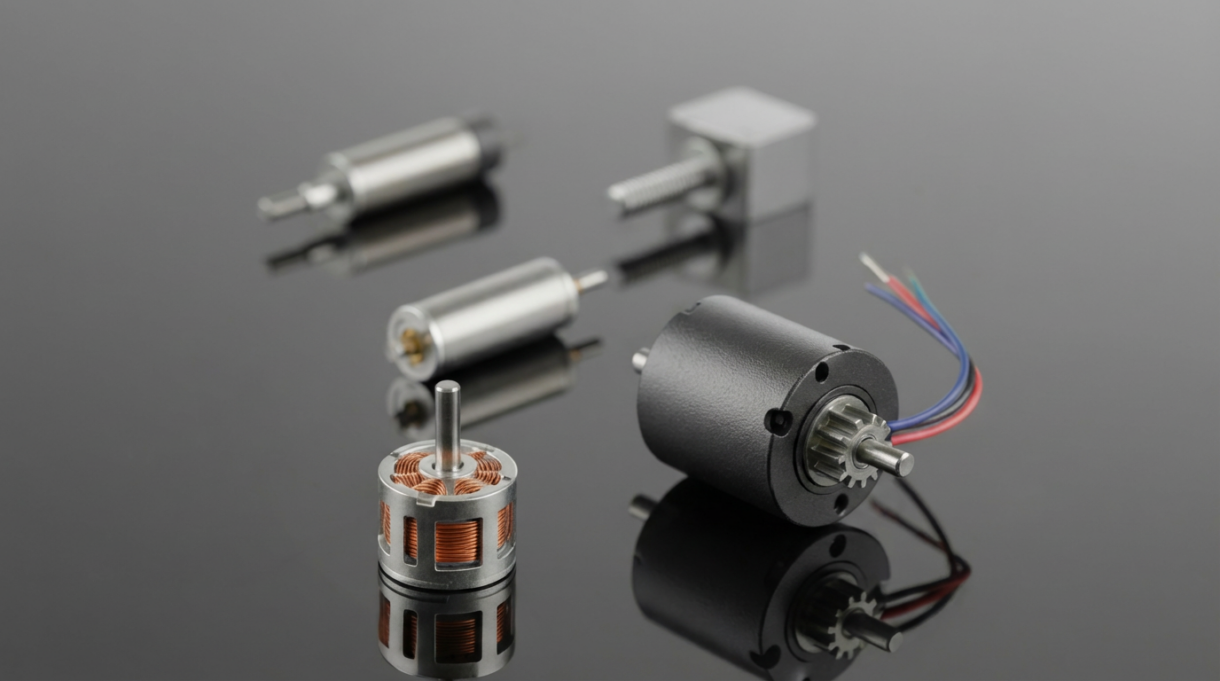

When it comes to selecting the perfect motor for your project, the options can feel overwhelming. At SLW Motor, we've spent years helping customers navigate the world of DC motors, and we know that understanding the different types available is the crucial first step. Whether you're working on robotics, automation, medical devices, or industrial applications, there's a specific motor type designed to excel in your use case.

In this comprehensive guide, we'll break down the main types of DC motors we manufacture, explain how they work, and help you understand which one might be right for your needs. Let's dive in.

The DC Motor Universe: Where Do You Start?

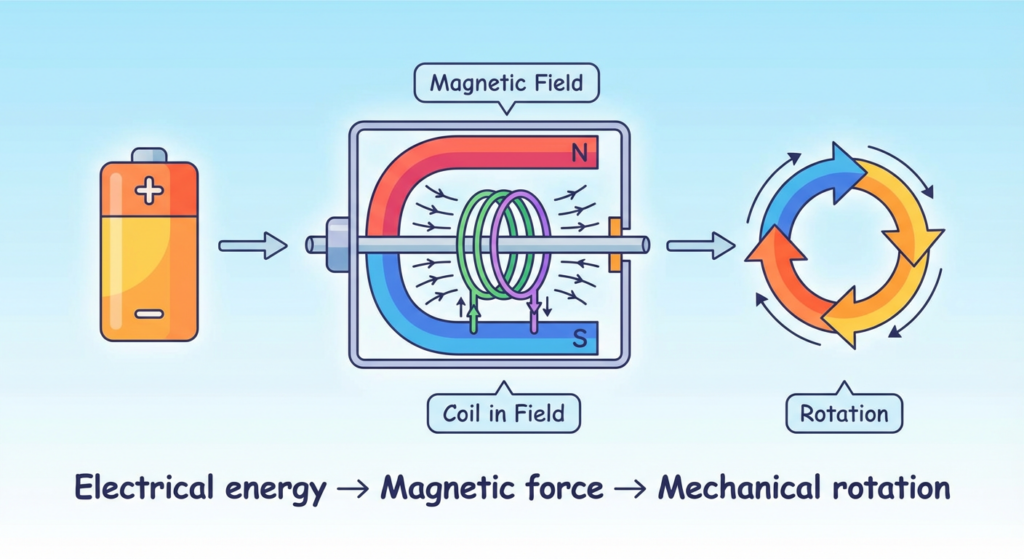

Before we explore the specific types, let's establish what all DC motors have in common. Every DC motor converts electrical energy into mechanical motion through the interaction of magnetic fields and electric current (See how magnetic fields interact to generate motion here.). The fundamental principle is elegant: when current flows through a conductor in a magnetic field, a force is generated. It's this simple physics that powers everything from toy cars to industrial machinery.

The real differences between motor types come down to how this electrical energy is delivered to the motor's rotating part, and how the internal components are designed. This is where our portfolio of motor types comes into play.

Brushed DC Motors: The Classic Choice

Let's start with brushed DC motors—the tried-and-true workhorses that have been around for over a century. If you've ever taken apart a toy motor or worked with standard DC motors, you've probably seen one of these.

How They Work

Brushed DC motors operate with a deceptively simple mechanism. Inside the motor, you'll find a rotating coil called the armature, permanent magnets, and crucially, a component called a commutator paired with brushes. The commutator is essentially a split ring that rotates with the armature, while the brushes are stationary contacts (typically made of carbon) that deliver current to the commutator.

Here's the magic: as the armature rotates, the brushes periodically switch the direction of current flowing through different sections of the coil. This switching is what keeps the motor spinning continuously. It's a mechanical solution to an electrical problem, and it's remarkably effective.

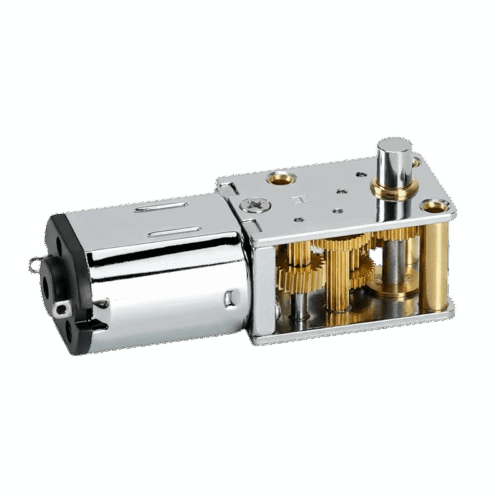

Brushed DC Motors

Durable brushed DC motors offering stable performance, strong starting torque, and cost-effective motion control.

Advantages

Brushed DC motors offer several compelling benefits:

- Simplicity and reliability: With fewer electronic components, these motors are straightforward to control and maintain

- Cost-effective: They're among the most affordable motors on the market

- High starting torque: They can deliver significant torque instantly, even from a standstill

- Wide speed range: They're easy to control across a broad range of speeds

- Robust performance: They handle shock loads and vibration well

Limitations

However, brushed motors aren't perfect:

- Brush wear: The brushes gradually wear down with use, requiring maintenance or replacement

- Electromagnetic interference: The brushes create electrical noise that can interfere with sensitive electronics

- Heat generation: Brush friction generates heat, reducing efficiency

- Speed limitations: They're not ideal for extremely high-speed applications

- Maintenance requirements: Regular inspection and brush replacement are necessary

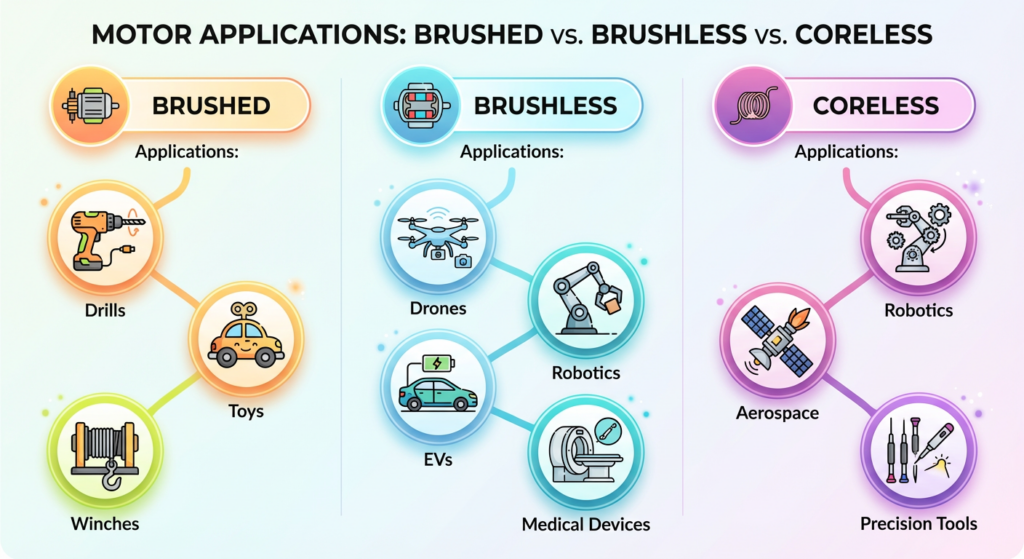

Real-World Applications

You'll find brushed DC motors in power drills, toy vehicles, industrial winches, and countless other applications where simplicity and reliability matter more than perfect efficiency.

Brushless DC Motors: The Modern Evolution

If brushed DC motors are the classics, brushless DC motors are the modern upgrade. Over the past few decades, they've become increasingly popular, and for good reason.

The Technology Behind Brushless Design

Brushless DC motors eliminate the brushes and commutator entirely. Instead, they use electronic switching to control the current direction in the motor windings. The result is a motor where the magnets rotate and the coils stay stationary—the opposite of a brushed motor.

This fundamental design change requires external electronics (called a motor controller or ESC—Electronic Speed Controller) to manage the switching, but the benefits are substantial.

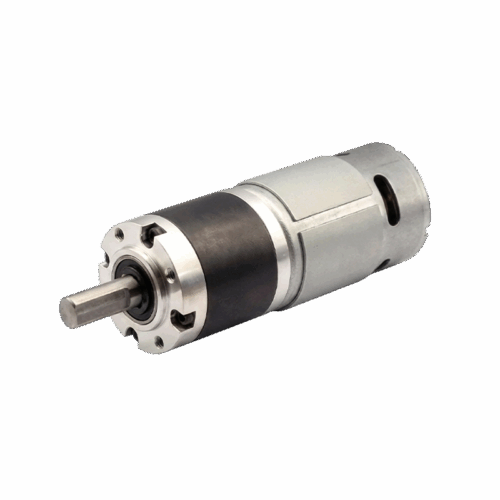

Brushless DC Motors

High-efficiency brushless DC motors engineered for long life, low noise, and precise speed control across industrial applications.

Why Choose Brushless?

The advantages of brushless technology are significant:

- Higher efficiency: Without brush friction losses, these motors can convert 85-90% of electrical energy into mechanical work

- Longevity: No brushes mean fewer wear parts and extended lifespan

- Low maintenance: They're essentially maintenance-free

- Clean operation: No electromagnetic interference or electrical noise

- Better heat management: Lower internal heat generation means better thermal characteristics

- Higher speed capability: They can safely operate at much higher RPMs than brushed equivalents

- Precise control: Electronic controllers enable very accurate speed and torque regulation

The Trade-Offs

Nothing's perfect, and brushless motors do have considerations:

- Higher cost: The electronic controller adds expense

- Complexity: They require more sophisticated control electronics

- Lower starting torque: They typically have lower peak torque compared to similarly-sized brushed motors

- Controller dependency: The motor's performance depends on the quality of the controller

Brushless DC motors are ideal for drones, electric vehicles, precision robotics, medical devices, and any application where efficiency, reliability, and low maintenance are priorities. They're particularly popular in applications where battery life is critical.

Coreless DC Motors: Lightweight Excellence

Here's where things get interesting. Coreless DC motors represent a specialized category that addresses a specific problem: weight and size constraints.

The Core Difference

Traditional DC motors—both brushed and brushless—have an iron core in their rotor. This core provides mechanical strength and helps conduct magnetic flux efficiently. But it also adds weight and inertia. Coreless motors eliminate this iron core, replacing it with a lightweight winding structure.

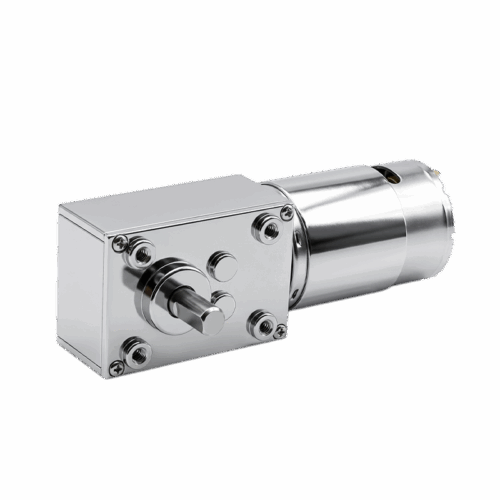

Coreless DC Motors

Ultra-light coreless DC motors providing rapid response, low inertia, and smooth rotation for high-precision devices.

Performance Characteristics

The absence of the iron core creates some fascinating performance traits:

- Lower inertia: The rotor accelerates and decelerates extremely quickly

- Lighter weight: For a given power output, coreless motors are significantly lighter

- Compact size: The smaller, lighter rotor means the entire motor package can be more compact

- Excellent acceleration: The low inertia makes these motors brilliant for applications requiring rapid acceleration

- High power-to-weight ratio: They deliver impressive performance in minimal space

The Physics of Low Inertia

The moment of inertia—a measure of an object's resistance to rotational acceleration—is dramatically reduced in coreless designs. This has cascading benefits: the motor responds more quickly to control inputs, wastes less energy accelerating and decelerating the rotor, and enables more dynamic control systems. For roboticists and engineers, this translates to more responsive, agile machines.

Applications Where Coreless Excels

These motors are perfect for:

- Robotics: Where quick, responsive movements are essential

- Aerospace and UAVs: Where every gram matters

- Medical devices: Where compact, lightweight solutions are needed

- Precision instruments: Where rapid response is critical

- Miniature applications: Where space is at a premium

Cost Consideration:Like brushless motors, coreless designs command a premium price. However, when you factor in size and weight savings, the value proposition often justifies the investment.

Choosing Between Motor Types

So how do you decide which motor type is right for your application? Here's a decision framework we recommend:

Ask yourself these questions:

- What's your power budget? If cost is the primary constraint, brushed DC motors offer unbeatable value.

- How important is efficiency? Running 24/7 or on batteries? Brushless or coreless motors will save you money long-term.

- What's your space constraint? Tight quarters demand coreless or brushless designs.

- Do you need low maintenance? Brushless and coreless are superior for set-and-forget applications.

- How important is startup torque? Need maximum force from standstill? Brushed motors excel here.

- What's your control complexity tolerance? Simple speed control favors brushed; sophisticated feedback control favors brushless.

- What's your duty cycle? Intermittent use tolerates brushed well; continuous operation benefits from brushless efficiency.

The Right Tool for the Job

At SLW Motor, we don't believe there's a universally "best" motor type—there's only the best motor for your specific application. Each type we manufacture—brushed, brushless, and coreless DC motors—serves distinct purposes and excels in particular situations.

The brushed motor remains a workhorse for cost-sensitive applications. The brushless motor has become the standard where efficiency and reliability matter. And the coreless motor opens possibilities for applications with severe size and weight constraints.

The key is matching the motor type to your application's unique requirements. Whether you're optimizing for cost, efficiency, performance, or some combination thereof, understanding these fundamental differences empowers you to make the right choice.

Ready to find your perfect motor? We're here to help. Contact our team, and let's find the solution that powers your innovation.