Stepper Gear Motors

High-precision stepper gear motors engineered for stable, low-speed motion control in automation, robotics, and industrial equipment.

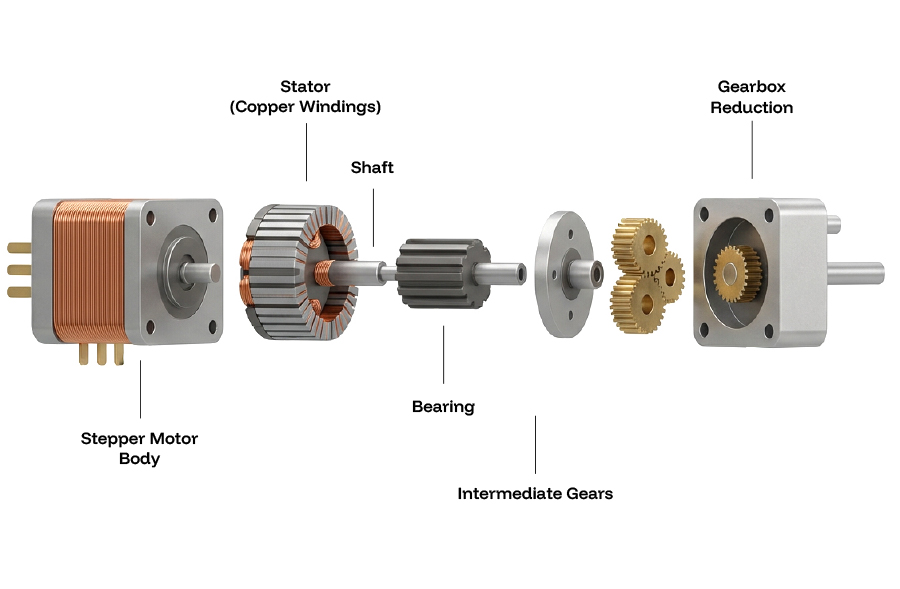

A stepper gear motor combines a stepper motor with a reduction gearbox, delivering controlled step-by-step rotation with higher torque at low speeds.

We offer custom voltage, sizes (Ø10–22 mm), gear types, and add-ons such as encoders or Hall sensors, ensuring a perfect fit for your specific design.

With 20 years of manufacturing experience and ISO 9001 certification, SLW Motor delivers reliable products with consistent quality and durability.

Our motors feature low noise, high torque, high efficiency, and smooth operation, meeting the needs of demanding precision systems.

SLW Motor provides complete gearbox solutions—planetary or spur—simplifying assembly and improving performance for your motor applications.

Stepper gear motors are widely used in robotic arms, pick-and-place systems, and automated production lines where accurate, repeatable positioning is essential. Their built-in gear reduction provides higher torque at low speeds, enabling smooth and stable motion for precise control tasks.

The combination of step-based movement and torque multiplication ensures reliable operation in compact automation systems.

Learn MoreFind quick answers to common stepper gear motor questions, from performance to customization.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.