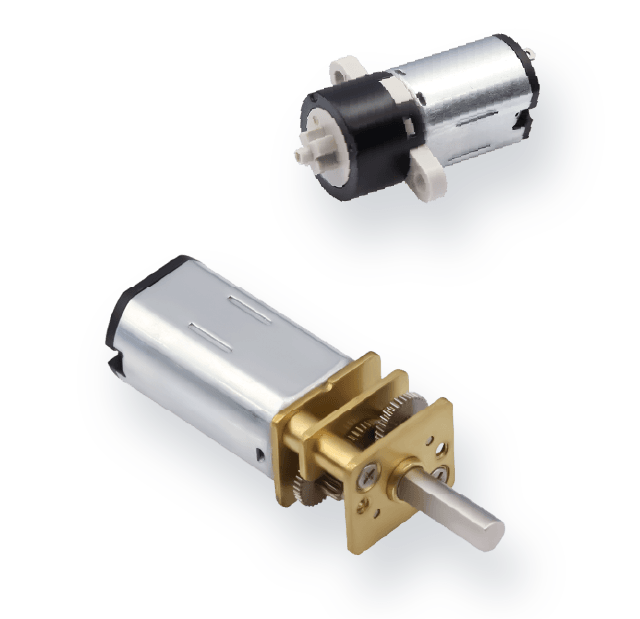

Precision Gears

Precision gears deliver reliable power transmission. Tight tolerances and optimized tooth geometry cut vibration, boost efficiency, and extend service life in automation and industrial drives.

Precision gears are critical components for accurate motion transmission and stable torque control in mechanical and motion control systems. We manufacture custom precision gears based on drawings and specifications, not standard catalog products.

Our precision gear solutions focus on:

Used for high-precision spur and helical gears with consistent tooth profiles and reliable dimensional accuracy.

Applied to medium-volume production where stable repeatability and cost efficiency are required.

Ideal for plastic precision gears requiring lightweight design, low noise, and high-volume production efficiency.

Used for high-load applications requiring strength, wear resistance, and long service life.

Selected for corrosion resistance, smooth operation, and applications where low friction is critical.

Suitable for lightweight systems, noise-sensitive environments, and cost-effective gear designs.

Our precision gear solutions are driven by engineering expertise and controlled manufacturing processes rather than standard product offerings.

We focus on selecting the most suitable manufacturing method for each gear design, maintaining tight dimensional control, and delivering consistent quality across production batches. This approach allows us to support complex gear designs while ensuring reliability, repeatability, and long-term performance.

Every precision gear project presents unique design and performance challenges. We provide full customization support across the manufacturing process, including:

Our engineering team works closely with customers to ensure manufacturability, precision consistency, and stable production quality throughout the project lifecycle.

Precision gears enable accurate, repeatable motion with reduced backlash, ideal for robotic joints, actuators, and positioning systems.

Learn MorePrecision is achieved through controlled manufacturing processes and systematic quality inspection. We emphasize dimensional accuracy, tooth profile consistency, and batch-to-batch stability to ensure reliable gear performance throughout the product lifecycle.

Find quick answers to the most common questions about our precision gears

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.