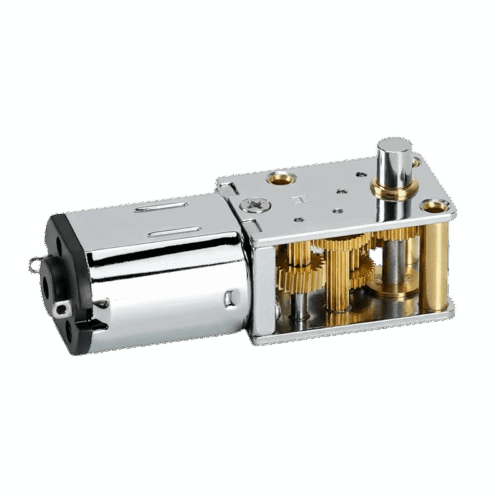

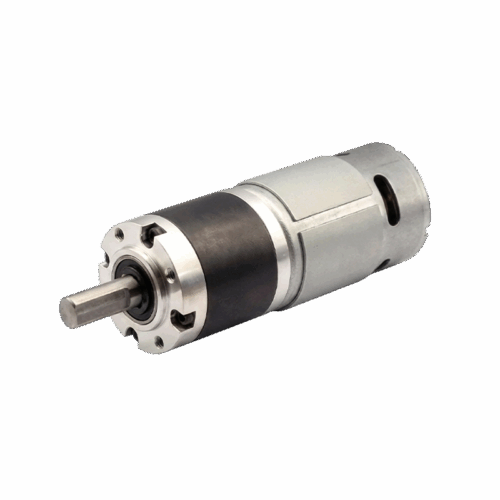

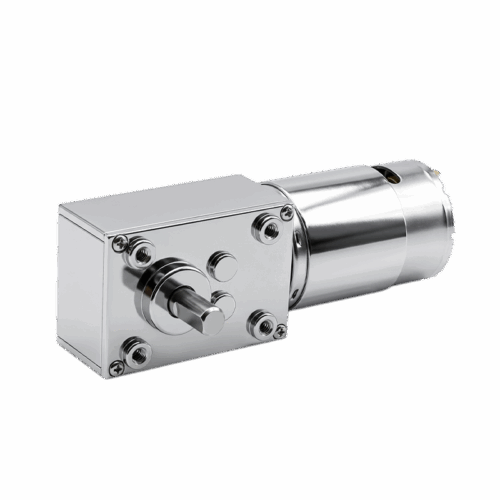

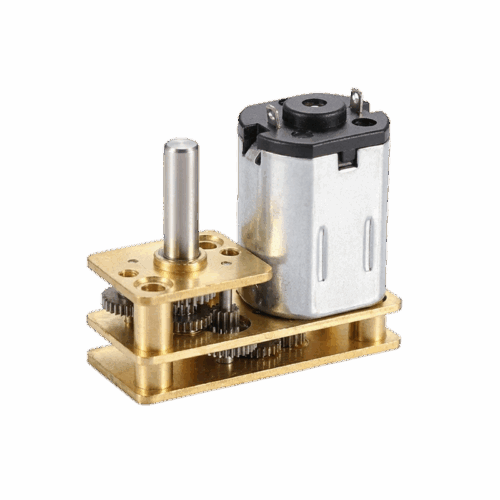

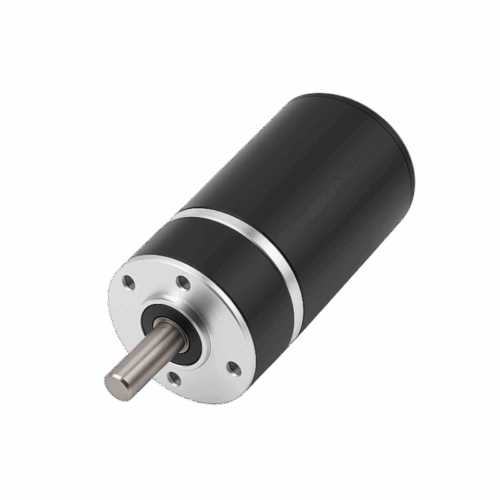

Mini Gearbox

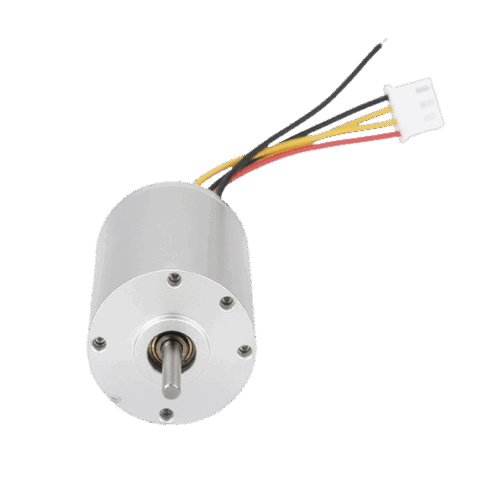

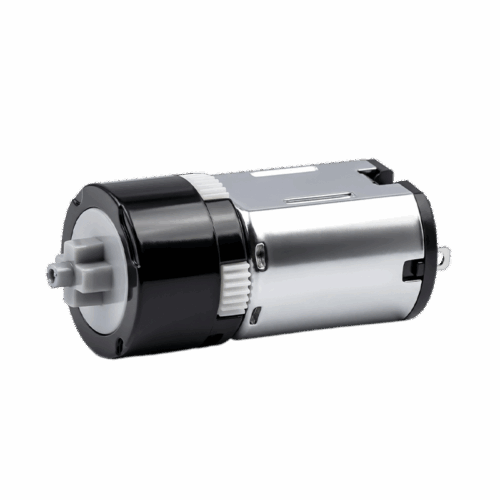

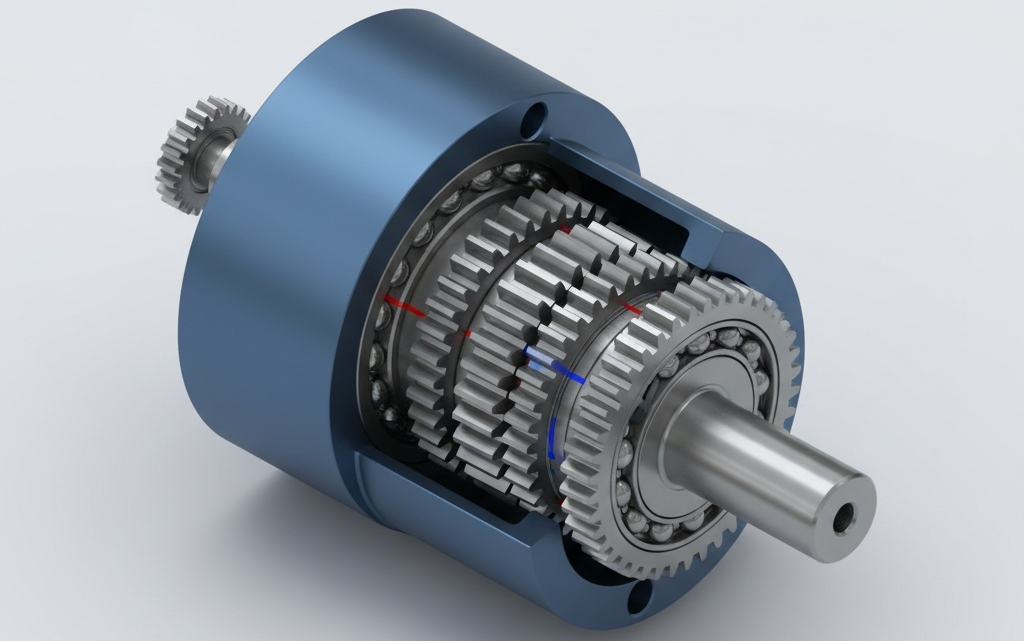

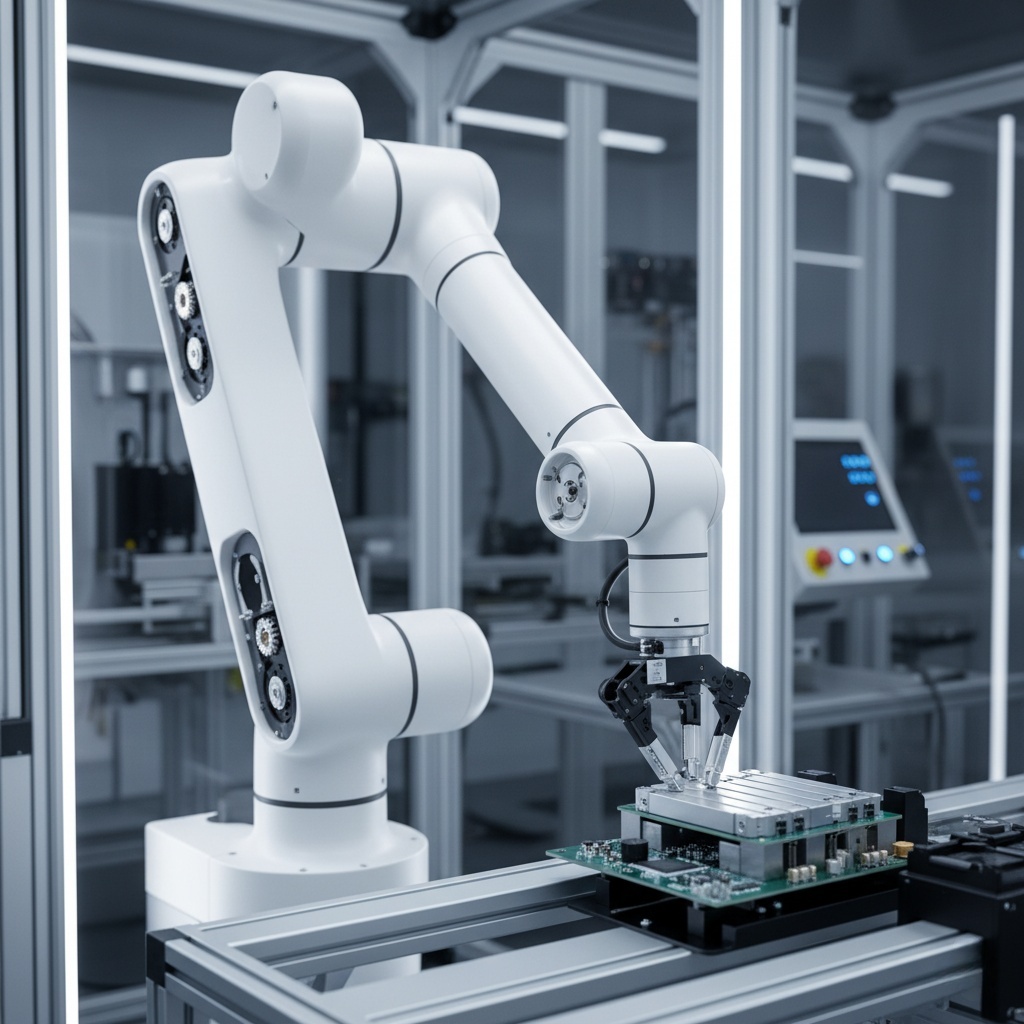

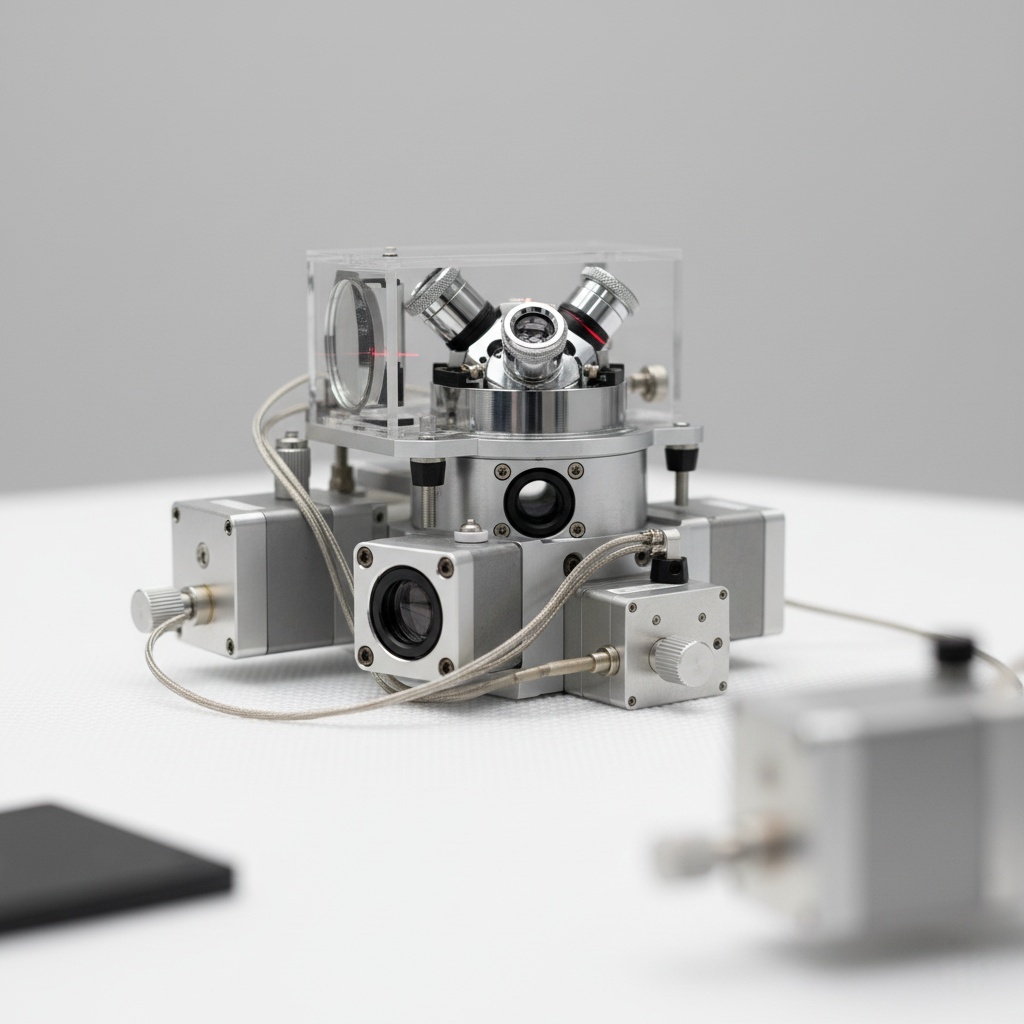

Mini gearboxes (gearheads) reduce speed and boost torque to deliver stable, controllable output for micro motors. Choose spur, planetary, or worm designs with custom ratios, shafts, and housings—built for robotics, medical devices, UAV payloads, and industrial automation.