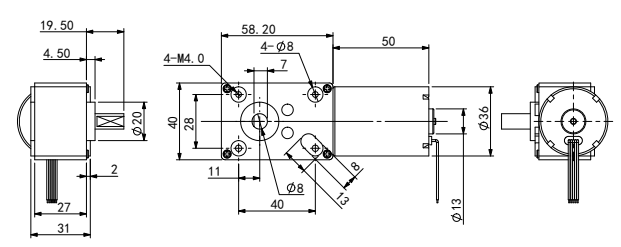

36mm Diameter BLDC Motor With Worm Gearbox

The 36mm brushless motor with worm gearbox combines efficient brushless drive and stable worm reduction, supporting controlled motion for applications requiring smoother operation and longer duty cycles.

Built around a 36mm brushless motor and a worm gearbox platform, this model focuses on drive efficiency and operational smoothness rather than purely mechanical size or load presence.

| Reduction ratio | No-Load | Rated Load | Stall | ||||||

| Rated Voltage (V) | Speed (RPM±10%) | Current (A) | Speed (RPM±10%) | Current (A) | Torque (Kg.cm) | Power (W) | Torque (Kg.cm) | Current (A) | |

| 15.5 | 12 | 516 | 0.55 | 432 | 3.5 | 2.5 | 25.6 | 9 | 12.2 |

| 25 | 12 | 320 | 0.55 | 280 | 3.5 | 5 | 25.6 | 14 | 12.2 |

| 31 | 12 | 258 | 0.55 | 210 | 3.5 | 10 | 25.6 | 16.5 | 12.2 |

| 50 | 12 | 160 | 0.55 | 125 | 3.5 | 15 | 25.6 | 28 | 12.2 |

| 62 | 12 | 129 | 0.55 | 105 | 3.5 | 20 | 25.6 | 33 | 12.2 |

| 73.5 | 12 | 108 | 0.55 | 98 | 3.5 | 20 | 25.6 | 40 | 12.2 |

| 96 | 12 | 83 | 0.55 | 73 | 3.5 | 25 | 25.6 | 55 | 12.2 |

| 100 | 12 | S0 | 0.55 | 72 | 3.5 | 25 | 25.6 | 55 | 12.2 |

| 120 | 12 | 66 | 0.55 | 55 | 3.5 | 30 | 25.6 | 65 | 12.2 |

| 147 | 12 | 54 | 0.55 | 44 | 3.5 | 30 | 25.6 | 68 | 12.2 |

| 156 | 12 | 51 | 0.55 | 42 | 3.5 | 35 | 25.6 | 70 | 12.2 |

| 193 | 12 | 41 | 0.55 | 32 | 3.5 | 35 | 25.6 | 80 | 12.2 |

| 239 | 12 | 33 | 0.55 | 28 | 3.5 | 40 | 25.6 | 90 | 12.2 |

| 313 | 12 | 26 | 0.55 | 21 | 3.5 | 50 | 25.6 | 100 | 12.2 |

| 328 | 12 | 24 | 0.55 | 20 | 3.5 | 50 | 25.6 | 110 | 12.2 |

| 448 | 12 | 17 | 0.55 | 14 | 3.5 | 60 | 25.6 | 200 | 12.2 |

| 657 | 12 | 12 | 0.55 | 9 | 3.5 | 80 | 25.6 | 400 | 12.2 |

| 896 | 12 | 9 | 0.55 | 7 | 3.5 | 80 | 25.6 | 400 | 12.2 |

For additional customization or reference configurations, please feel free to contact us.

For detailed selection guidance or project-specific requirements, please contact our team for further support.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.