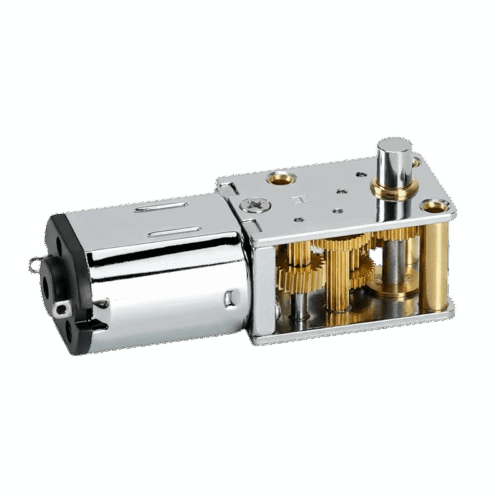

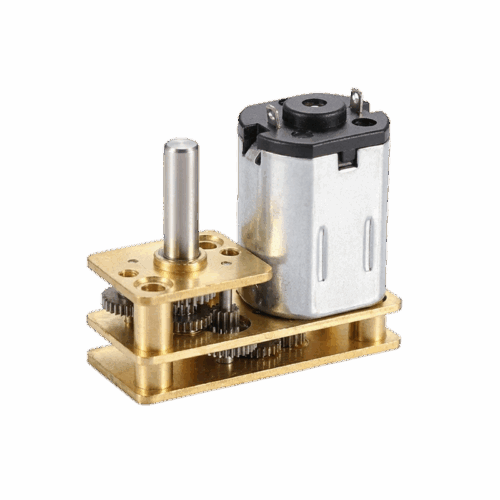

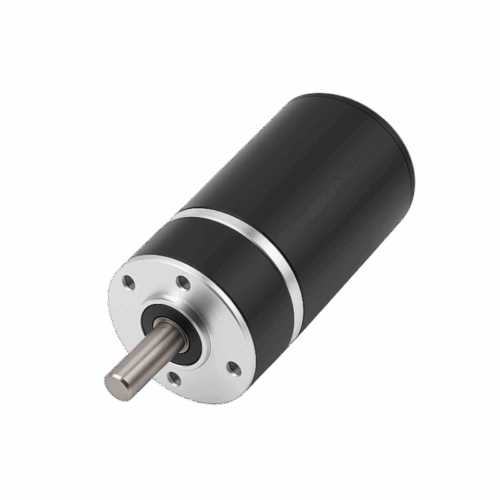

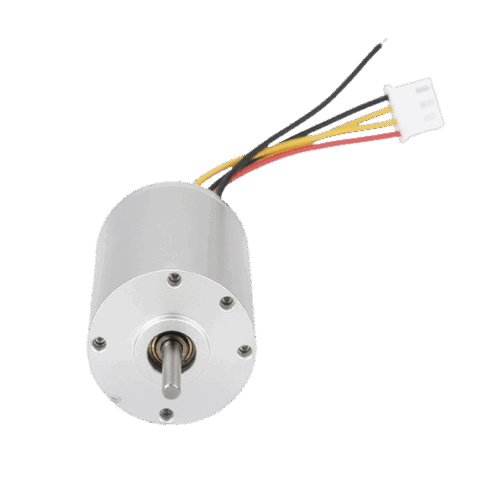

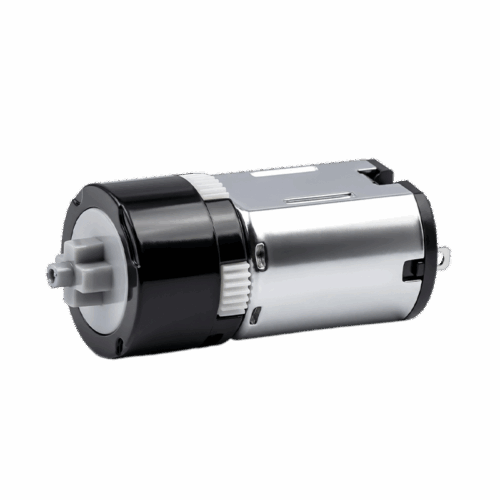

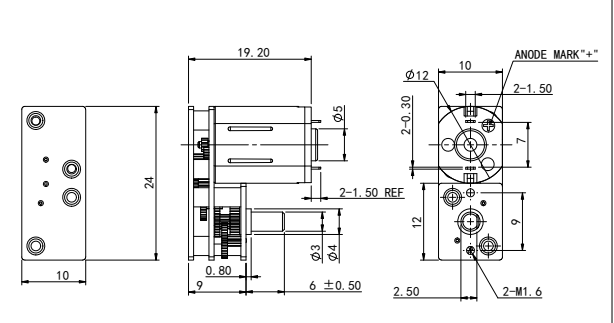

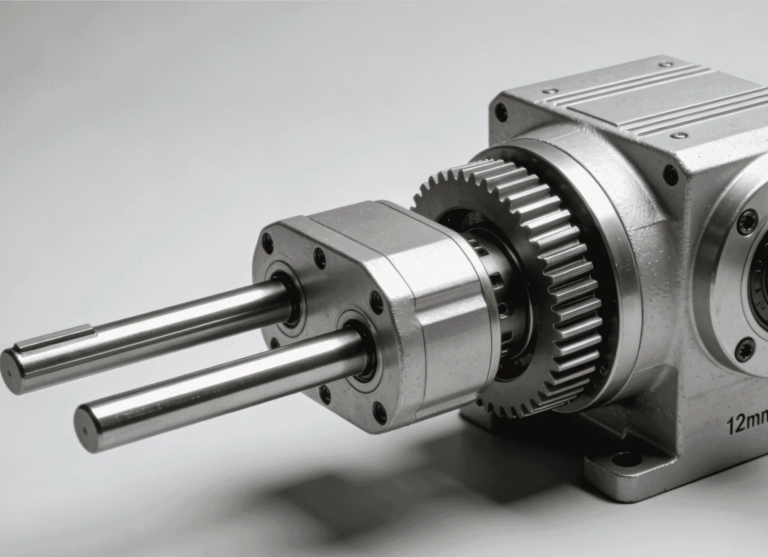

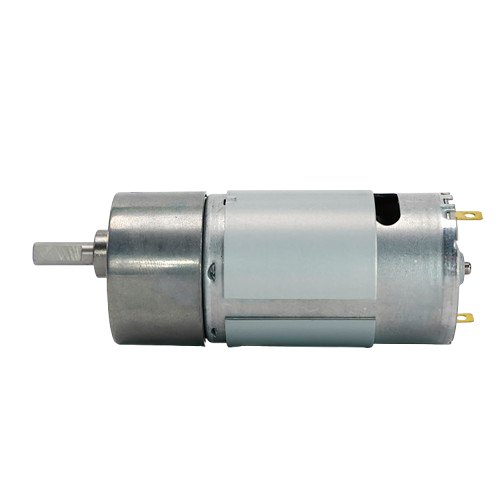

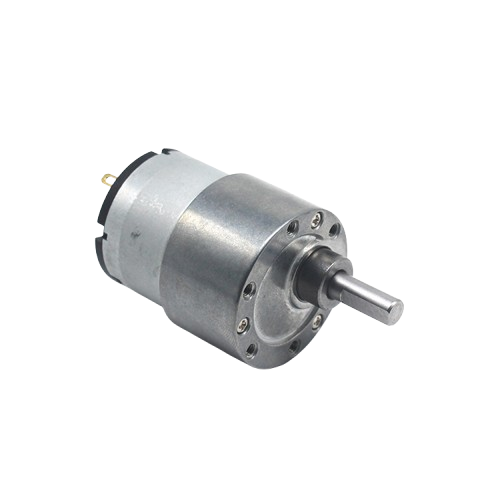

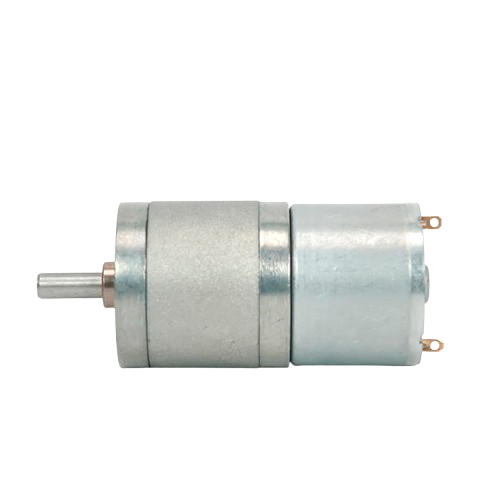

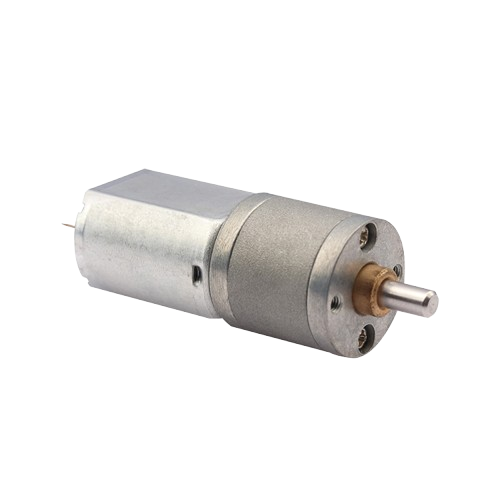

12mm Diameter Brushed Motor WithParallel Output Shaft Gearbox

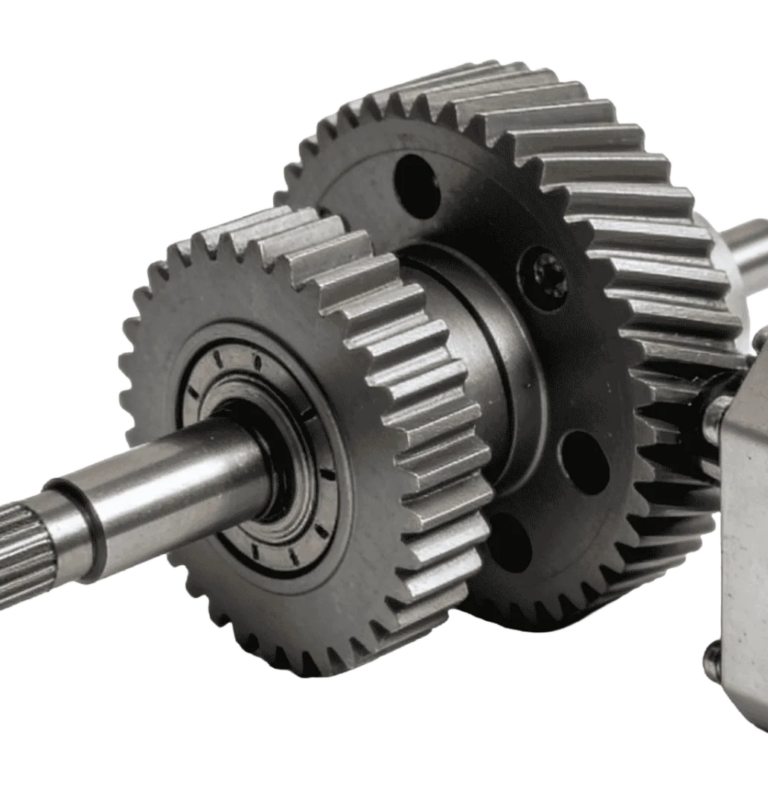

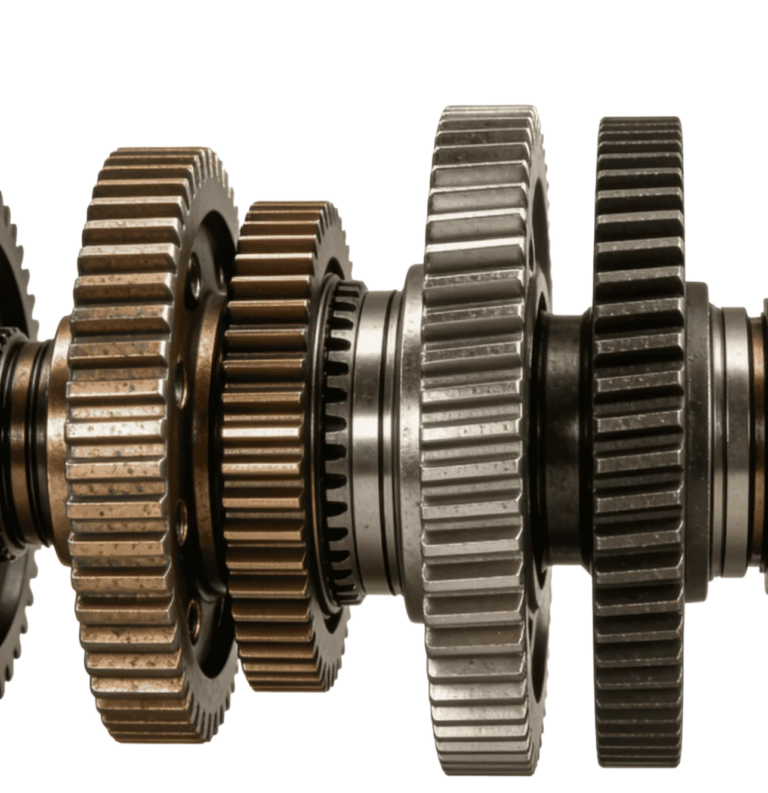

This 12mm N20 micro brushed motor with parallel output shaft gearbox is designed for applications requiring compact size with offset shaft alignment, supporting flexible installation in confined mechanical layouts.