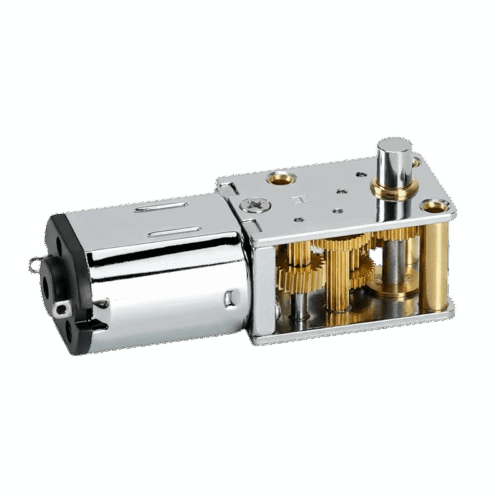

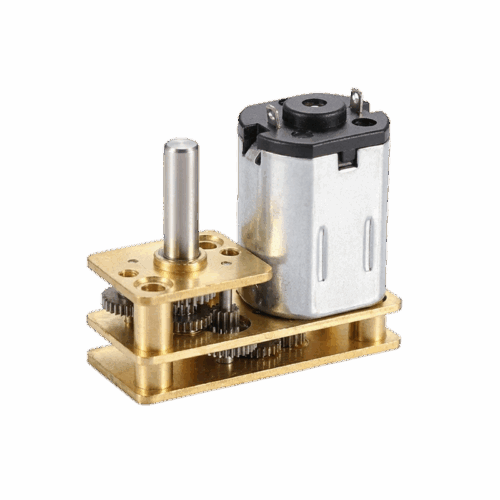

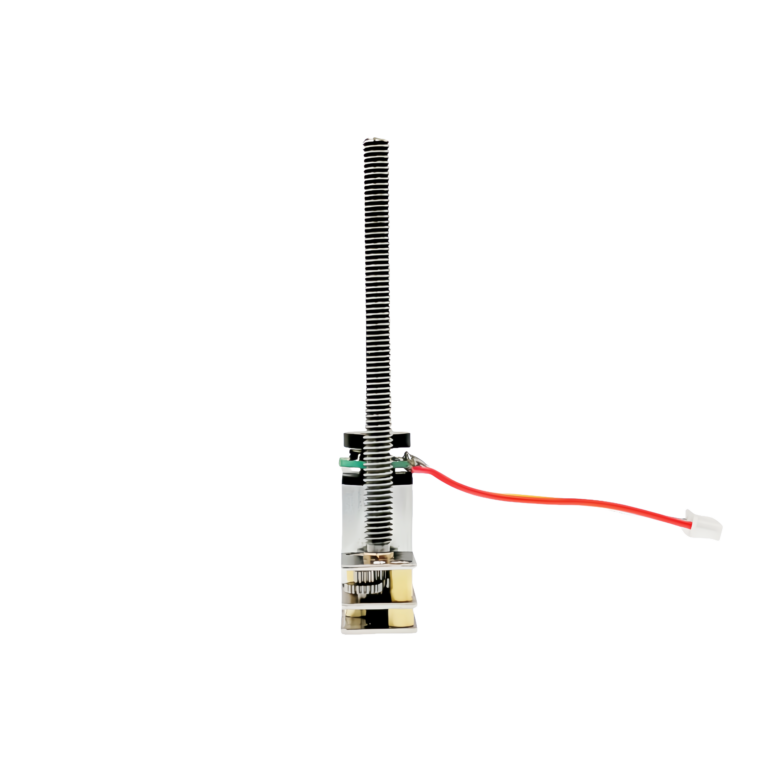

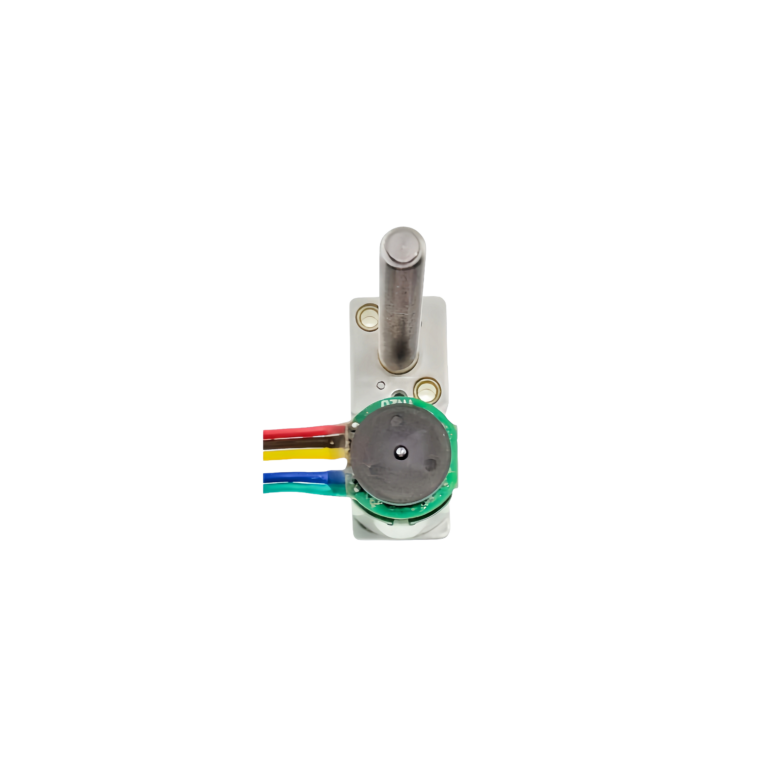

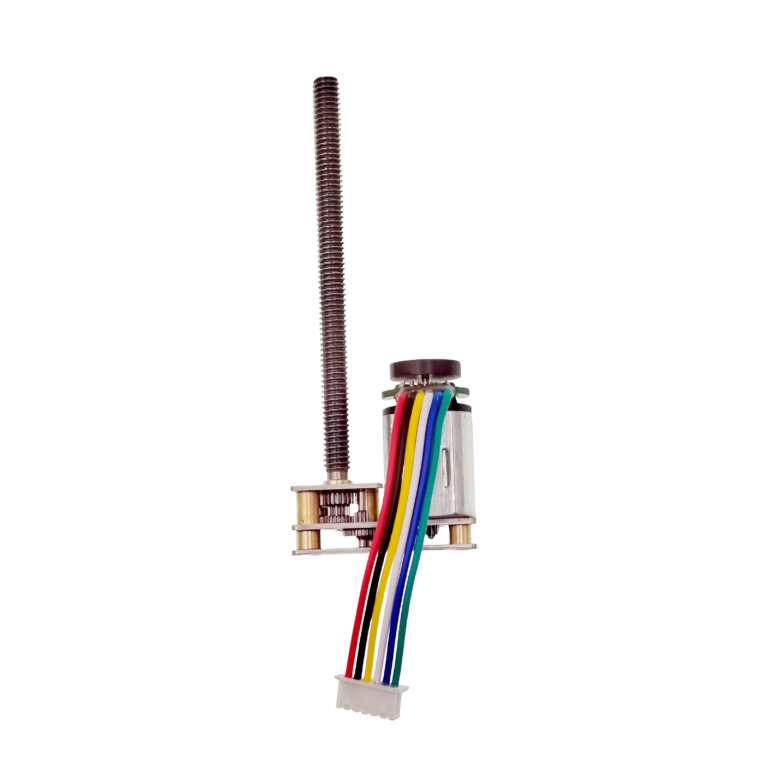

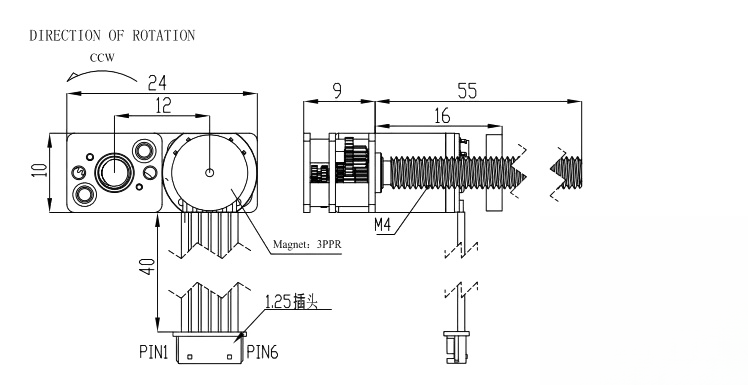

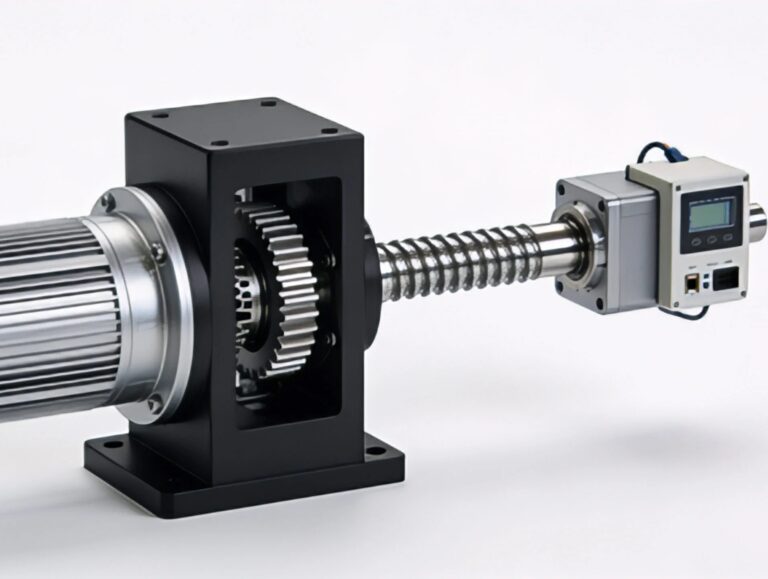

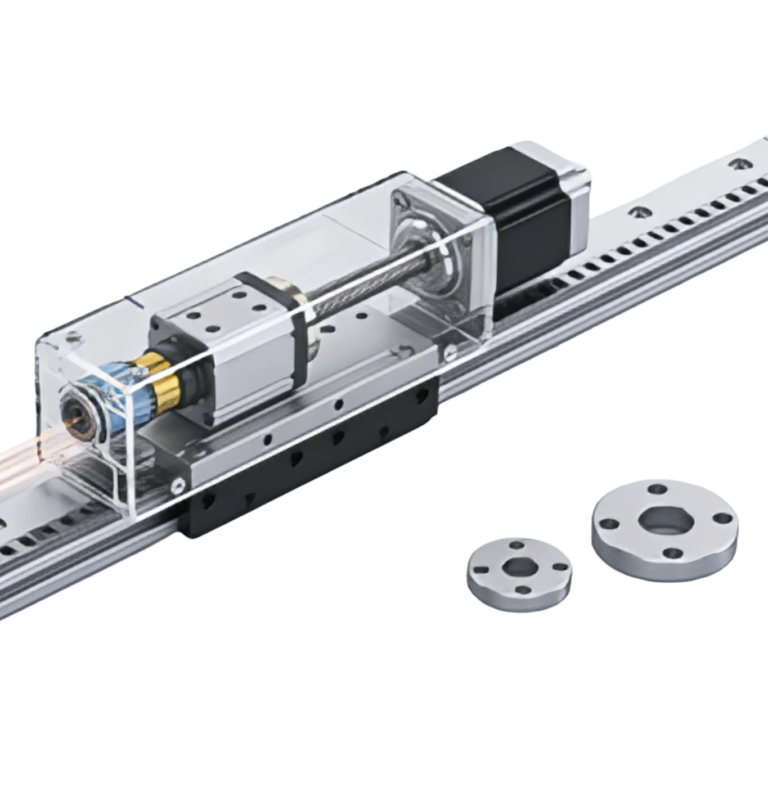

12mm Diameter Brushed Motor with M4 Screw Output Shaft Gearbox

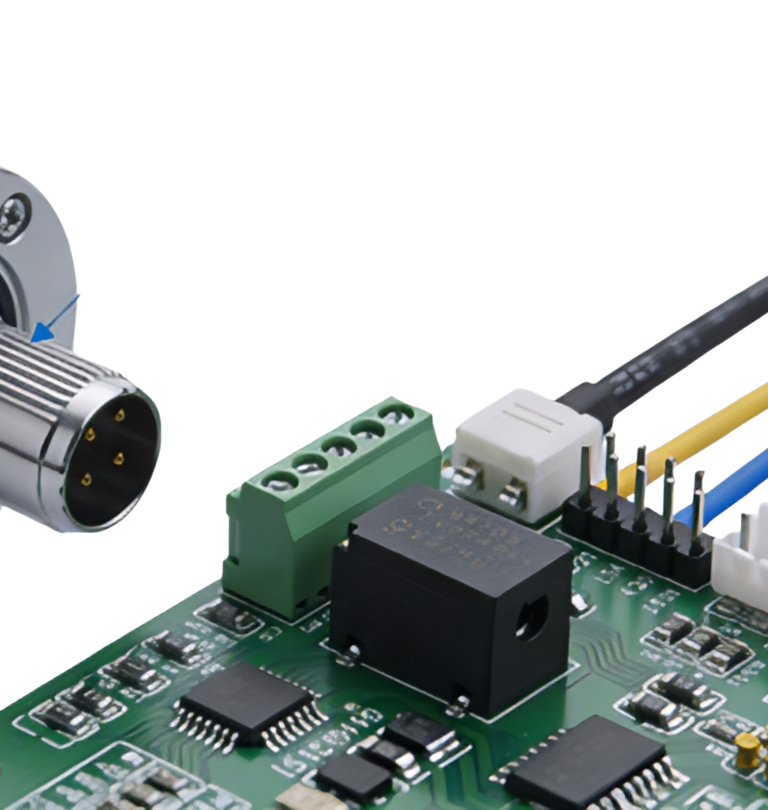

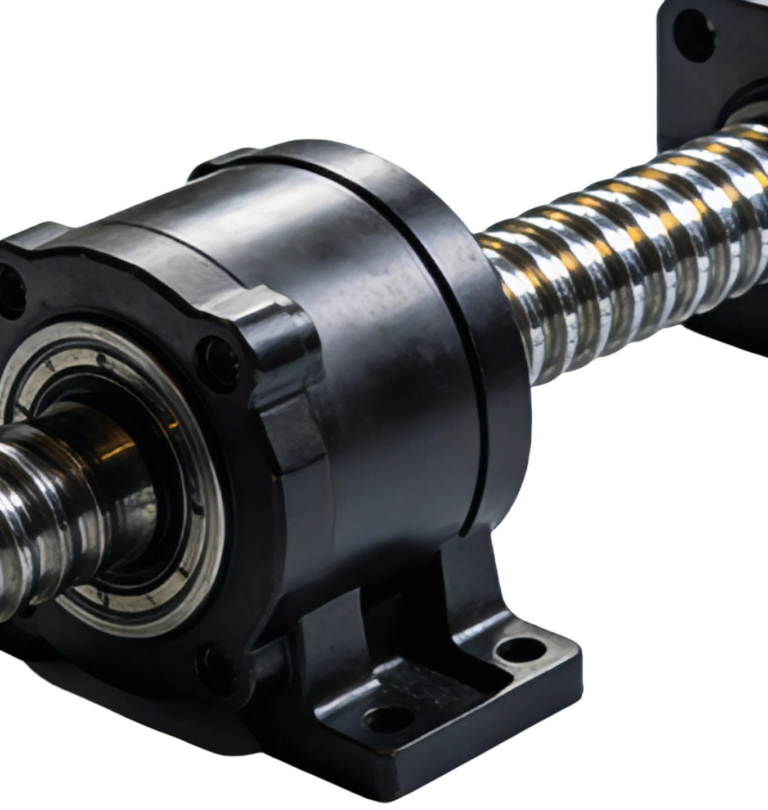

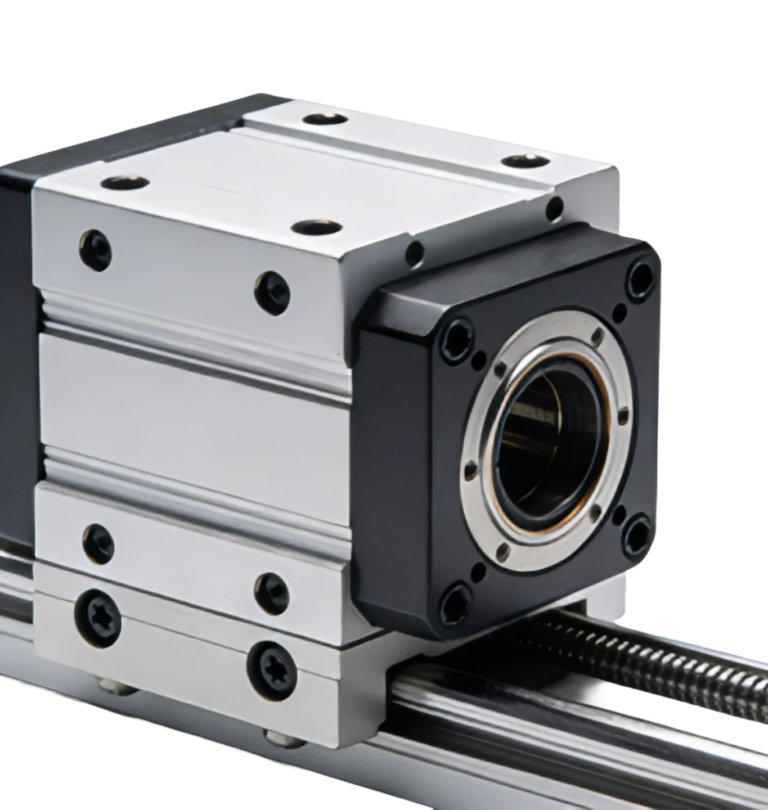

The 12mm brushed motor with screw shaft gearbox and encoder is designed for compact linear motion systems, combining rotational drive, screw transmission, and position feedback in a single assembly.