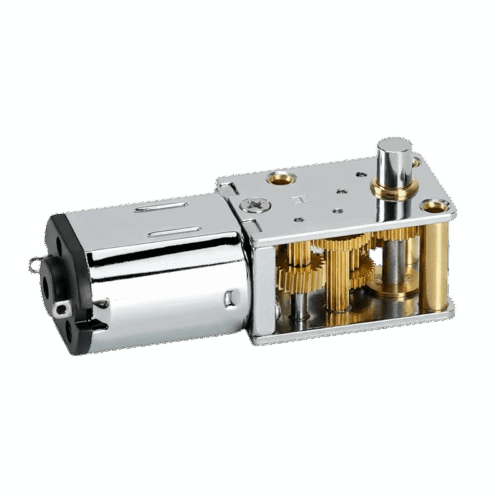

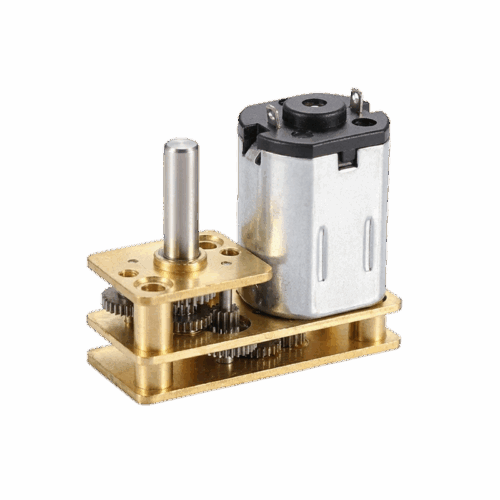

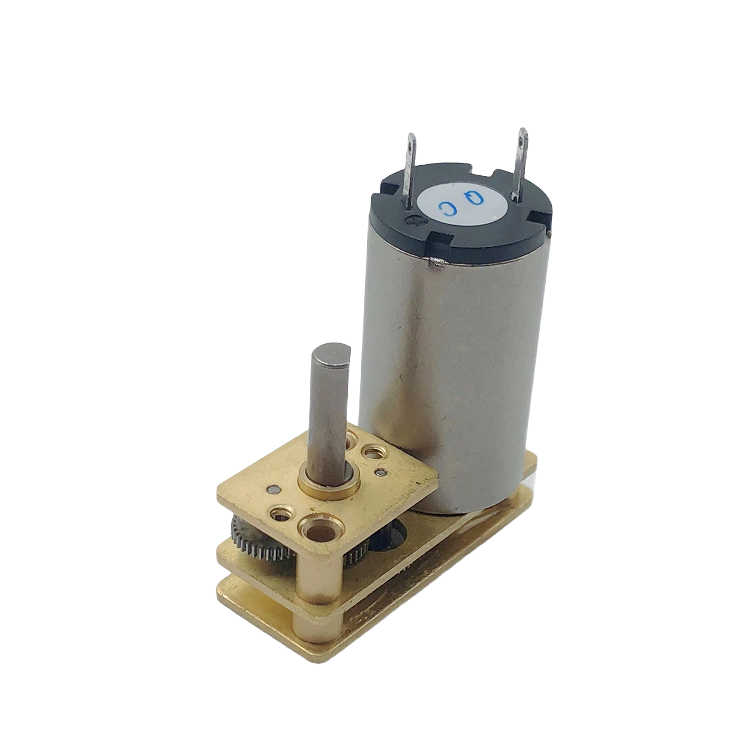

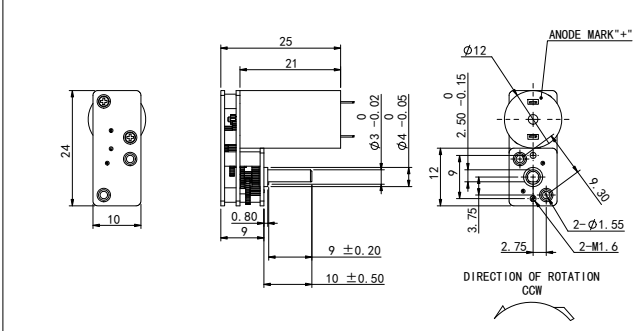

12mm Diameter Brushed Coreless Motor WithParallel Output Shaft Gearbox

The 12mm brushed coreless motor with parallel output shaft gearbox is designed for compact inline drive layouts, supporting smooth rotational transmission in space-constrained electromechanical systems.