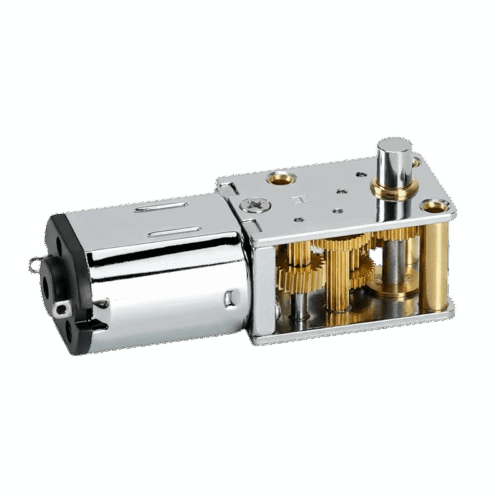

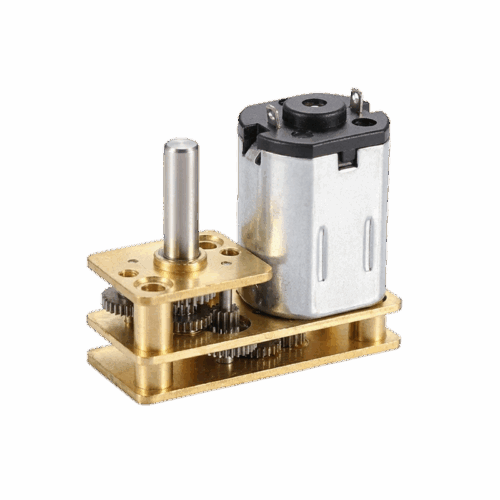

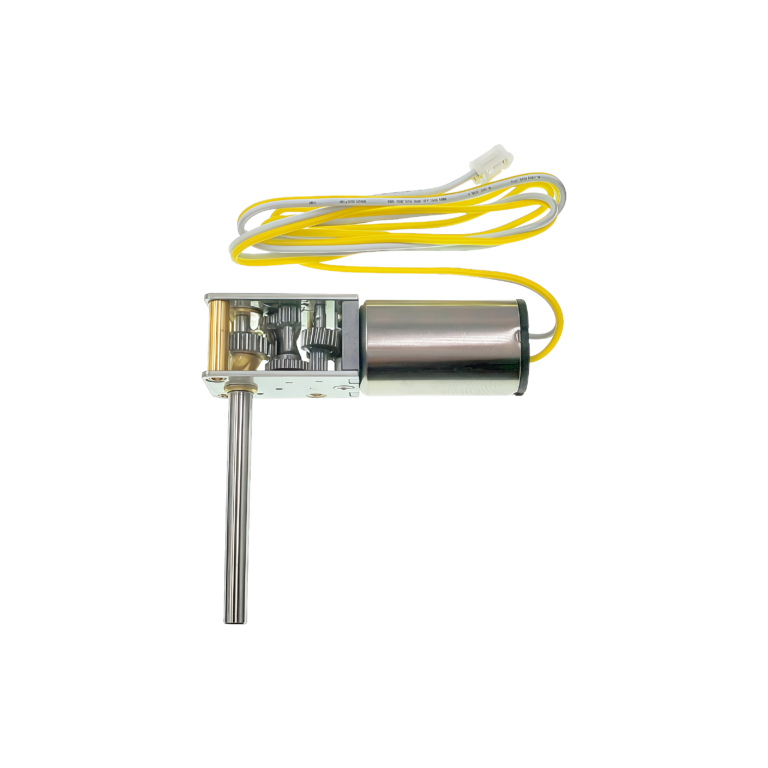

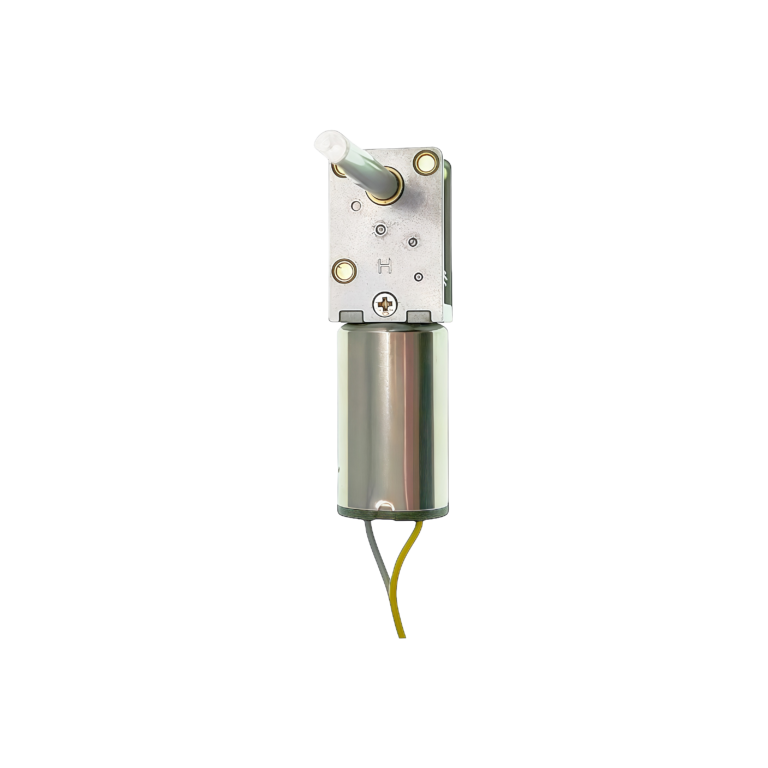

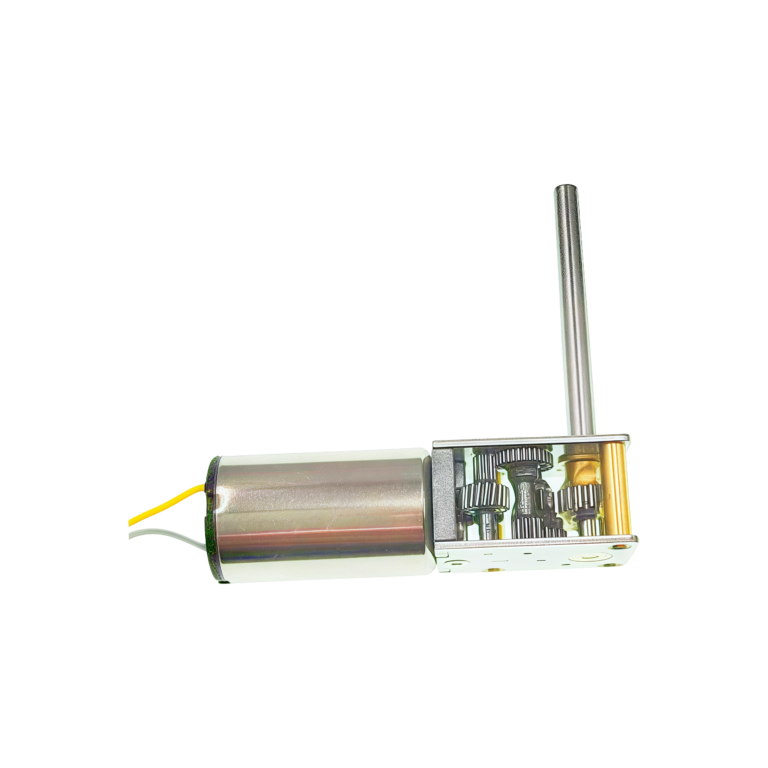

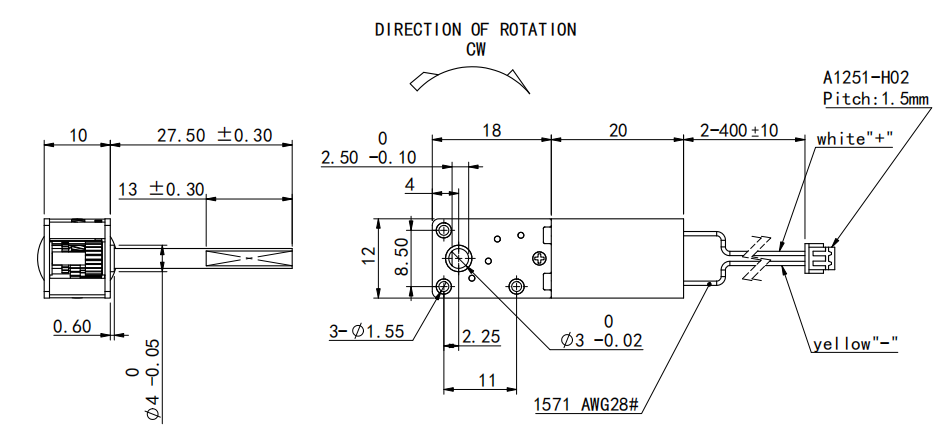

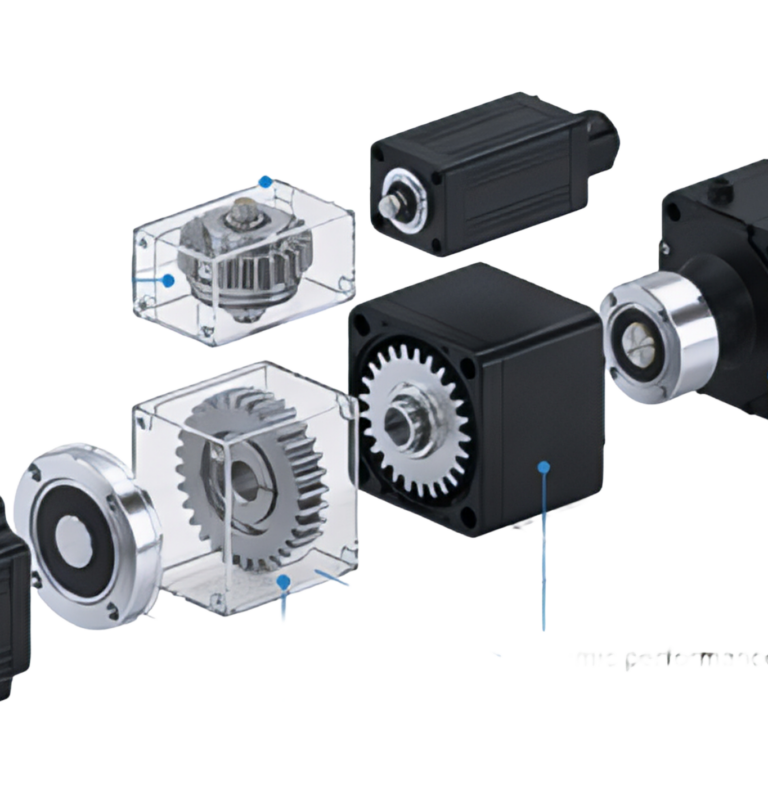

12mm Diameter Brushed Coreless Motor With Worm Gearbox

The 12mm coreless motor with 90-degree shaft gearbox focuses on smooth response and low inertia performance, supporting compact mechanisms that require precise motion control within limited space.