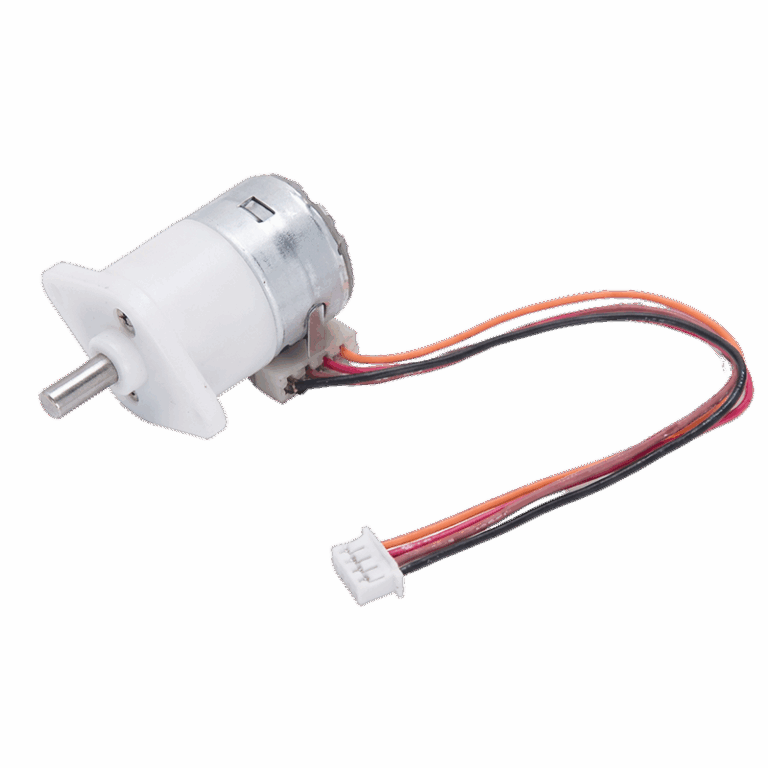

Stepper Motors

Precision stepper motors for accurate, repeatable positioning in automation, robotics, and motion-control systems.

A stepper motor divides rotation into precise steps, allowing controlled movement without needing feedback sensors.

We offer custom voltage, sizes (Ø10–22 mm), gear types, and add-ons such as encoders or Hall sensors, ensuring a perfect fit for your specific design.

With 20 years of manufacturing experience and ISO 9001 certification, SLW Motor delivers reliable products with consistent quality and durability.

Our motors feature low noise, high torque, high efficiency, and smooth operation, meeting the needs of demanding precision systems.

SLW Motor provides complete gearbox solutions—planetary or spur—simplifying assembly and improving performance for your motor applications.

Stepper motors are widely used in robotic arms, automation modules, and motion-control platforms where precise, repeatable positioning is essential. Their step-by-step movement enables accurate path control, smooth transitions, and reliable performance without feedback sensors.

This makes them ideal for compact robotic assemblies, pick-and-place systems, and automated production equipment.

Learn MoreExplore the essential information you need when selecting and using stepper motors.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.