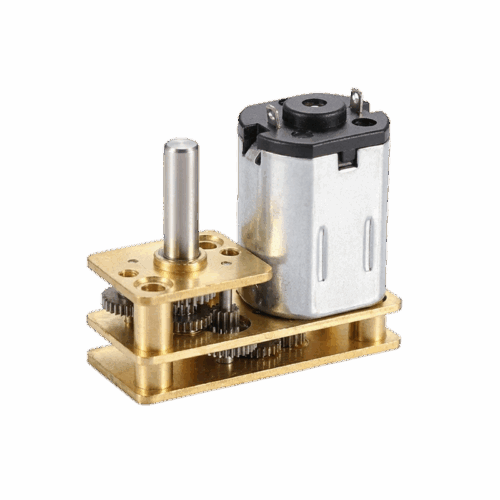

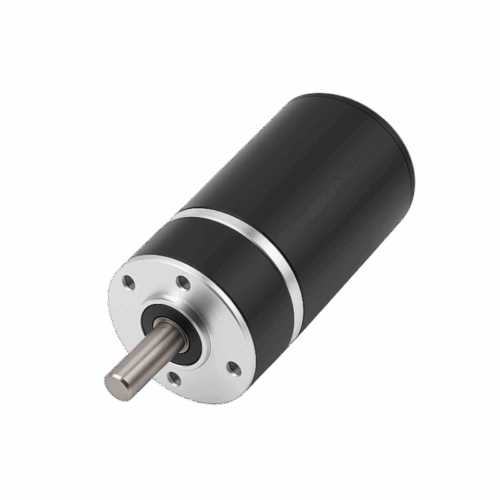

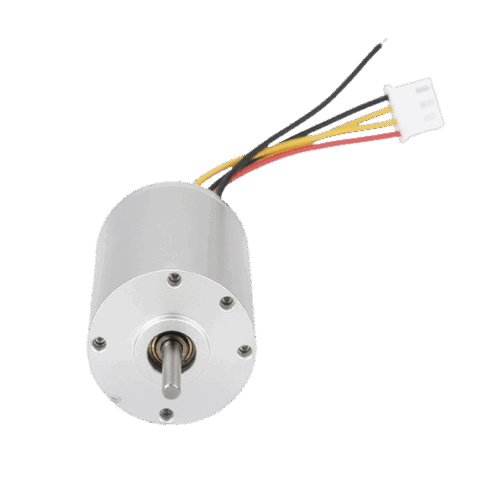

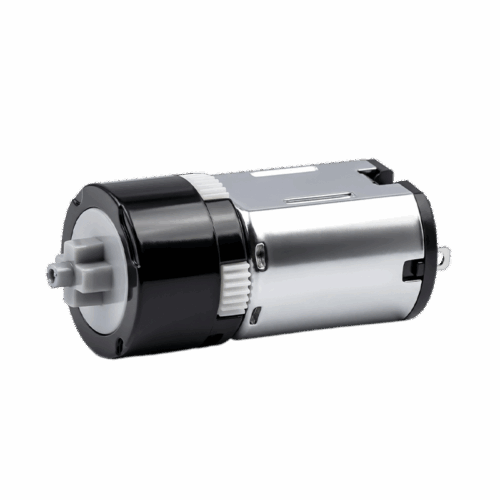

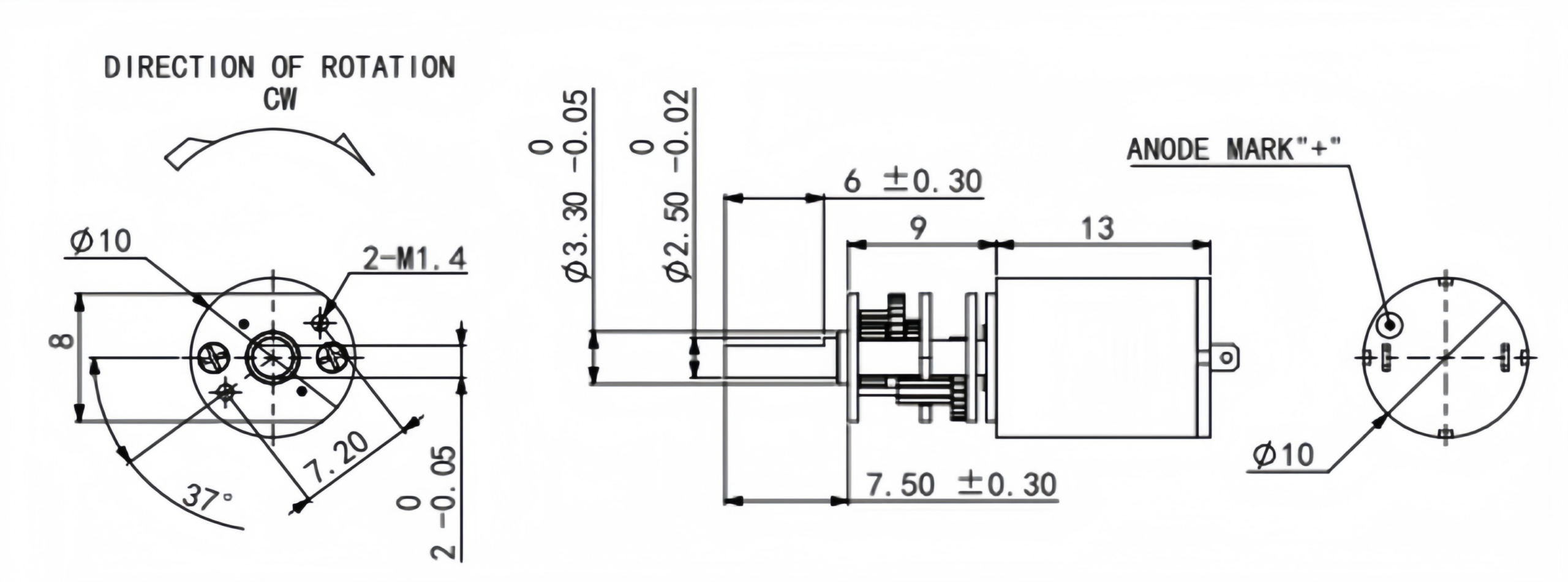

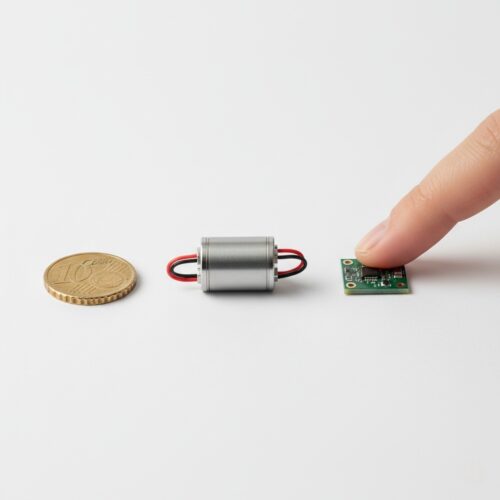

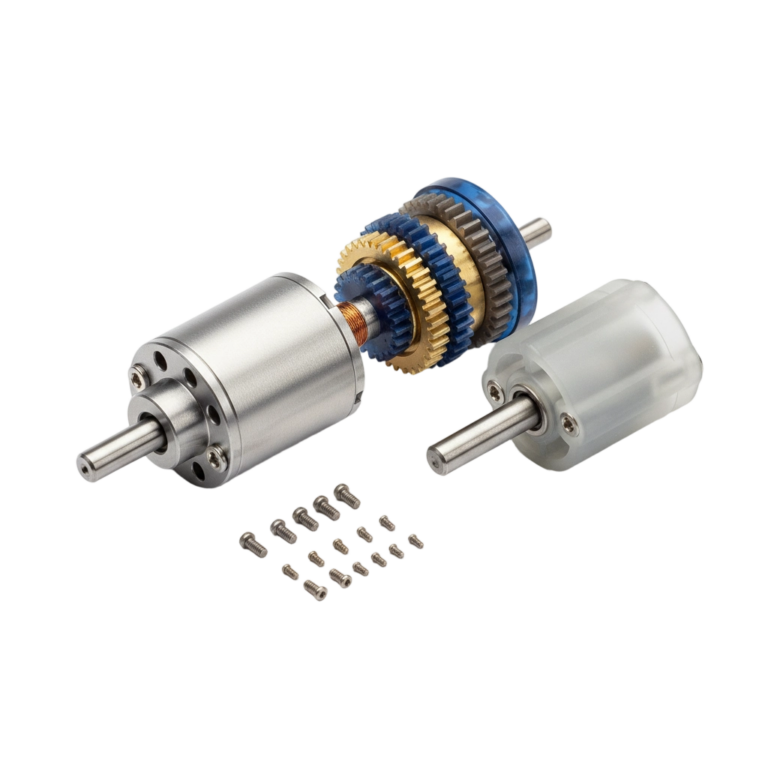

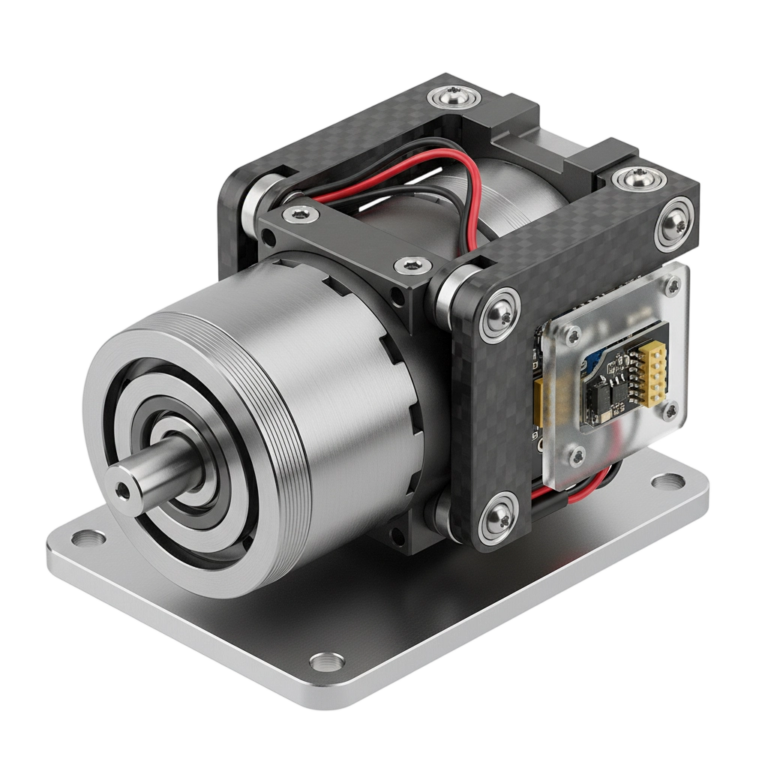

10mm Diameter Brushed Coreless Dc Motor With Gearbox

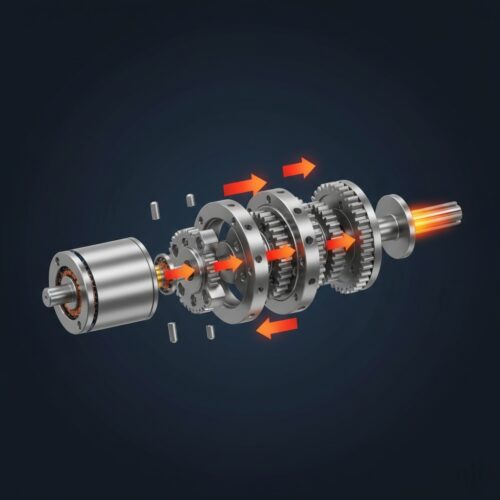

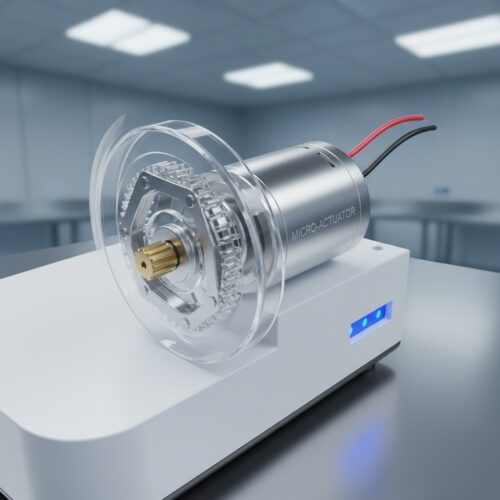

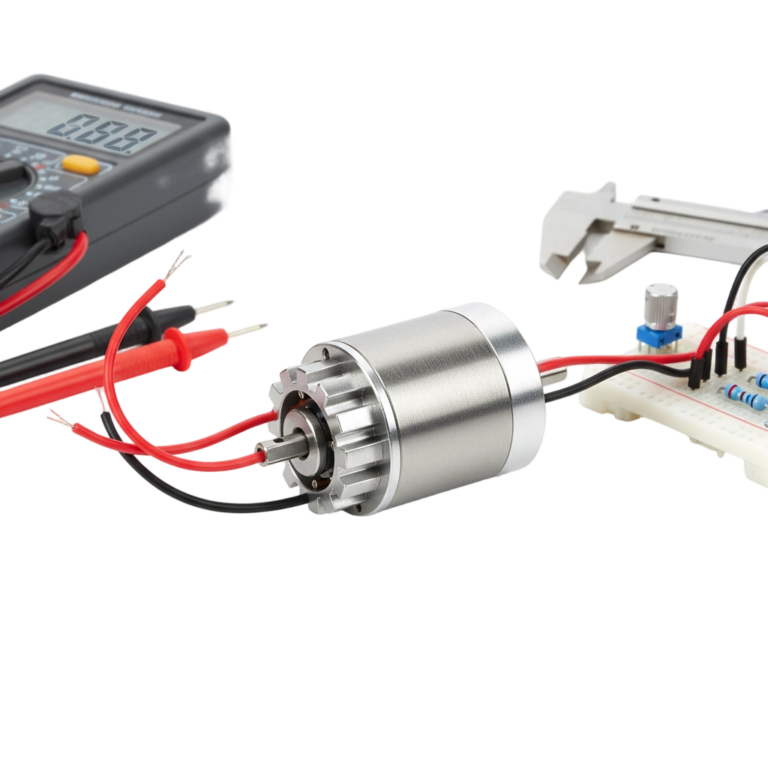

The 10mm diameter brushed coreless DC motor with gearbox is designed for compact drive systems that require smooth rotation, fast response, and stable torque output within limited installation space.