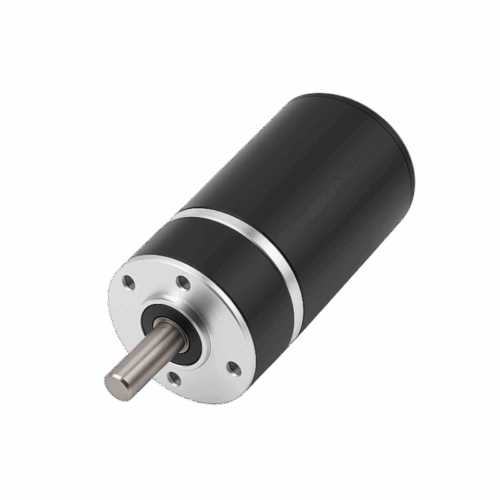

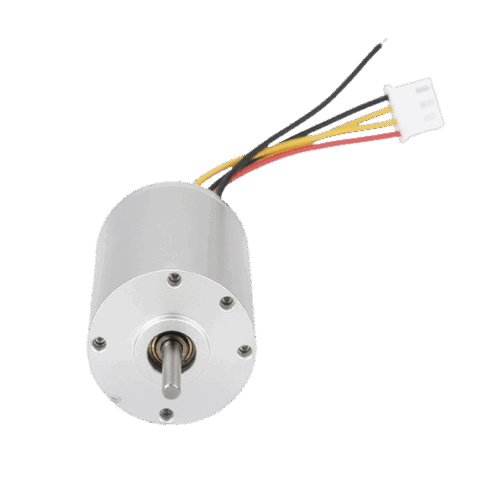

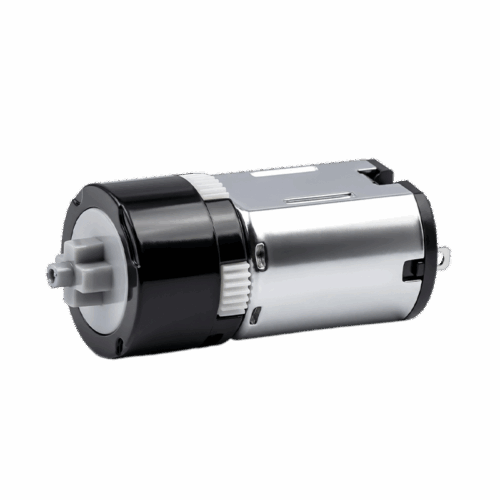

Power tools & Portable Equipment

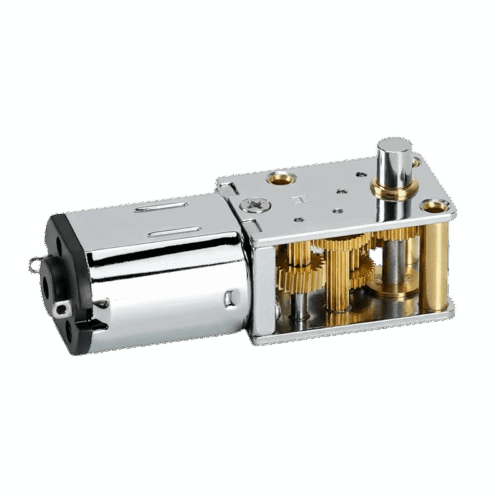

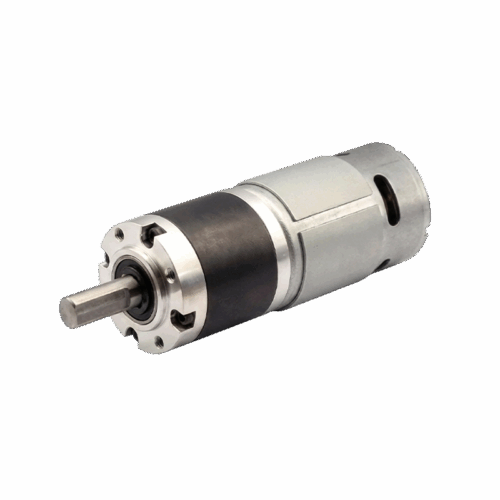

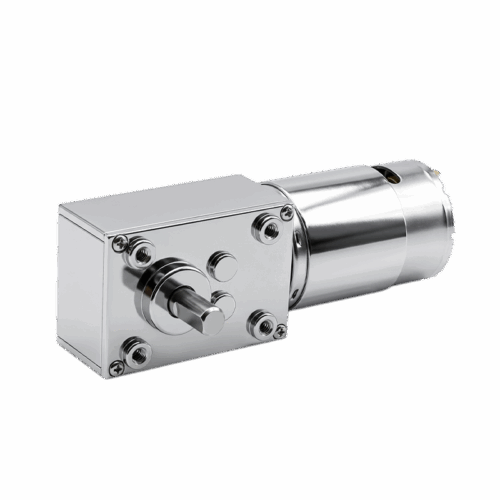

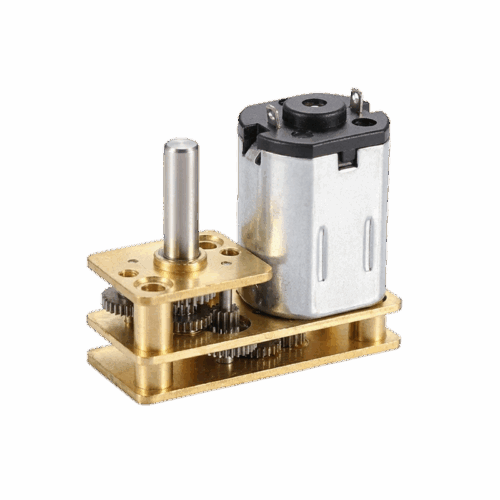

Power tools and portable equipment require motors that deliver strong torque, fast response, and consistent performance under demanding load conditions. Our miniature motors and gear motors provide the durability, efficiency, and reliability needed for handheld devices used in construction, DIY, maintenance, and field operations.