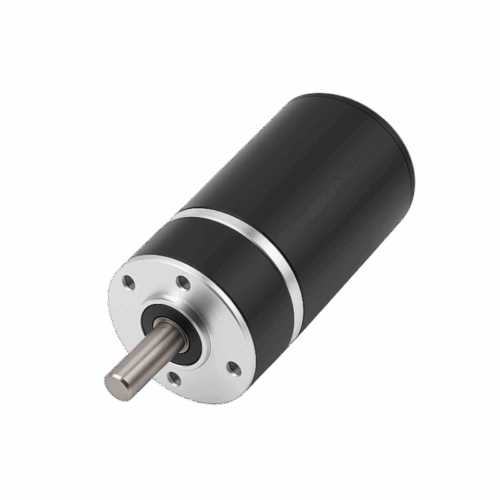

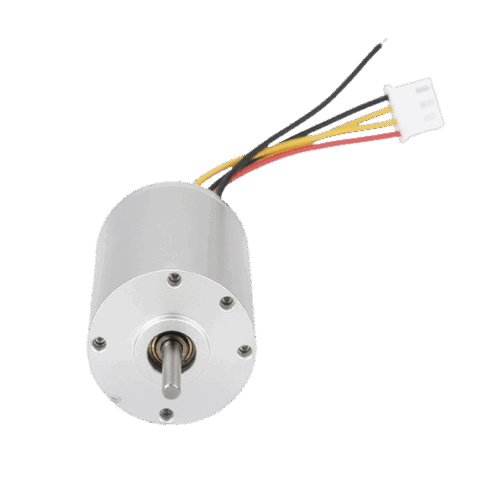

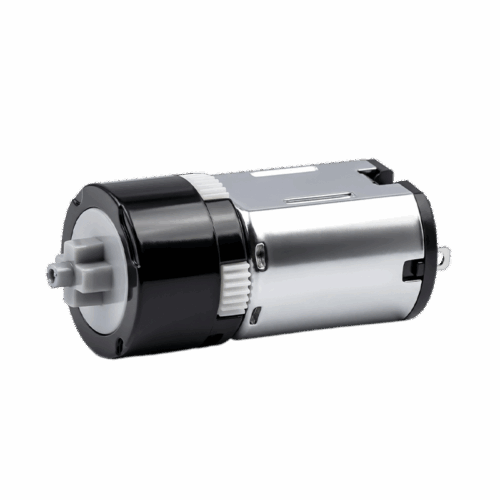

Medical Equipment

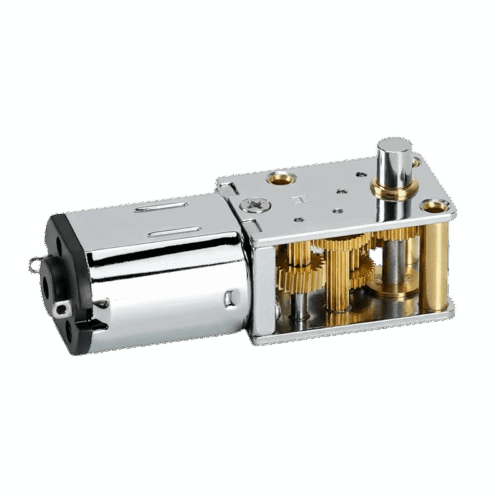

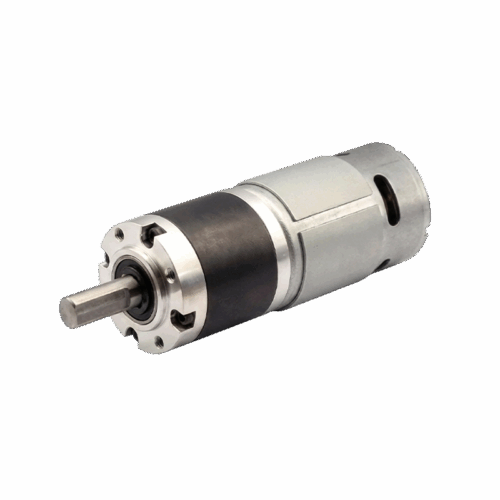

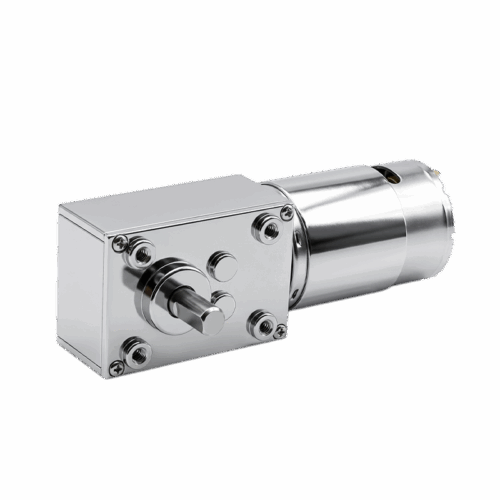

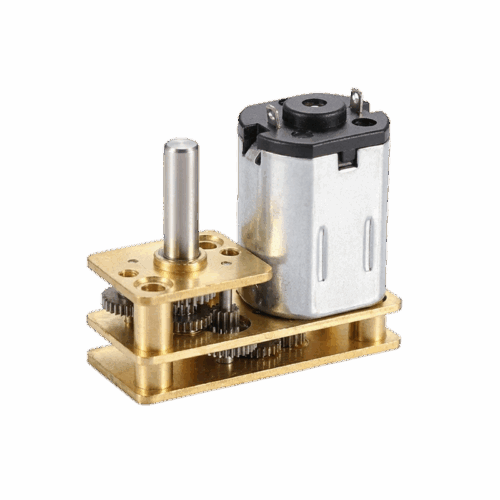

Medical devices require motion systems that are precise, quiet, compact, and highly reliable. Our miniature motors and gear motors deliver the accuracy, smooth movement, and long service life needed for diagnostic, surgical, and patient-care equipment.