Industrial Machinery

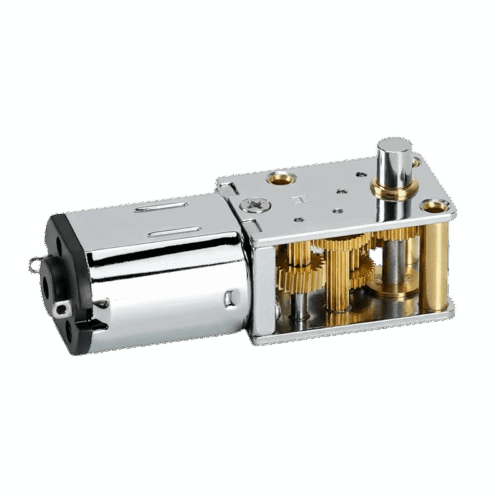

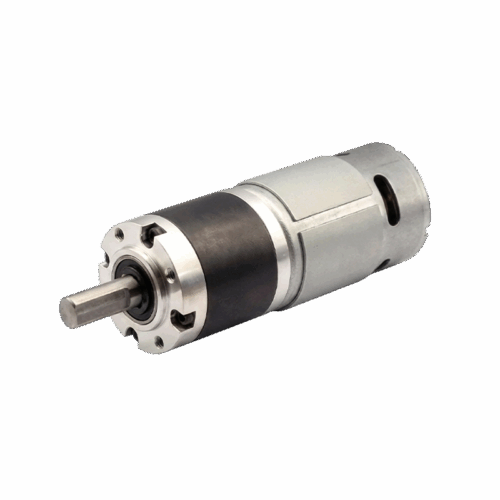

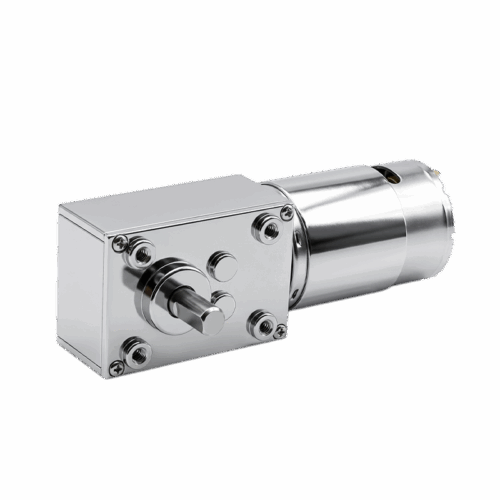

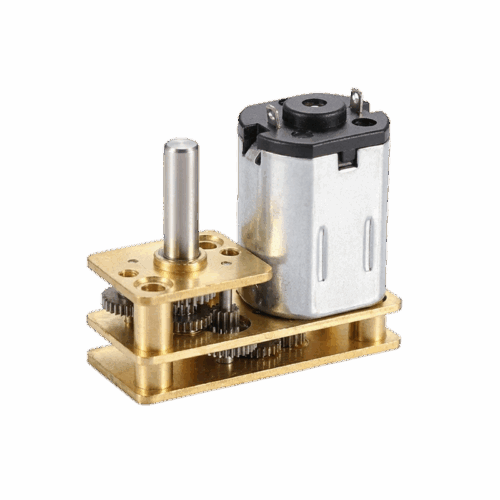

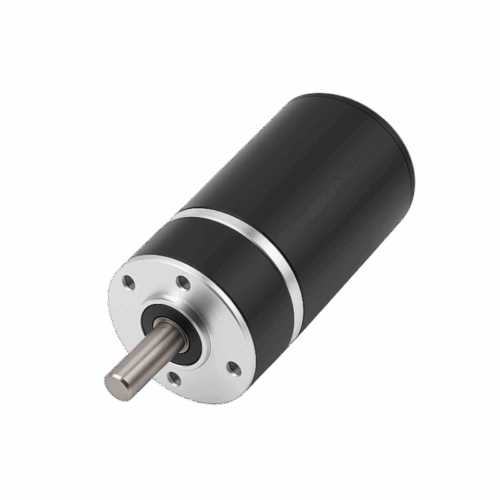

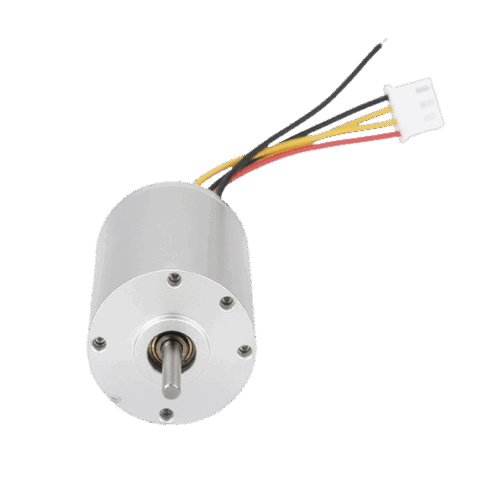

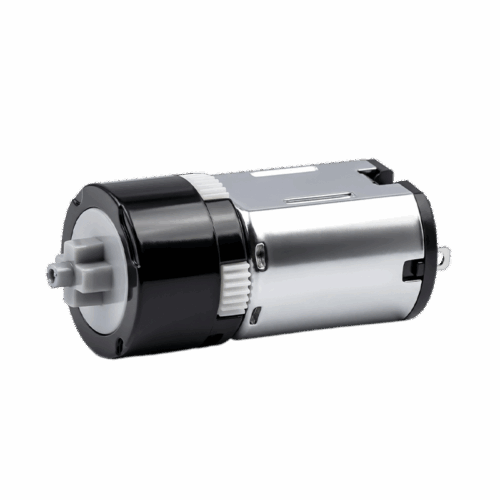

Industrial machinery requires motors that deliver consistent torque, long operational life, and stable performance under demanding conditions. Our precision micro motors and gear motors are engineered to withstand continuous loads, harsh environments, and high-duty cycles across a wide range of industrial equipment.