Aerospace & Defense

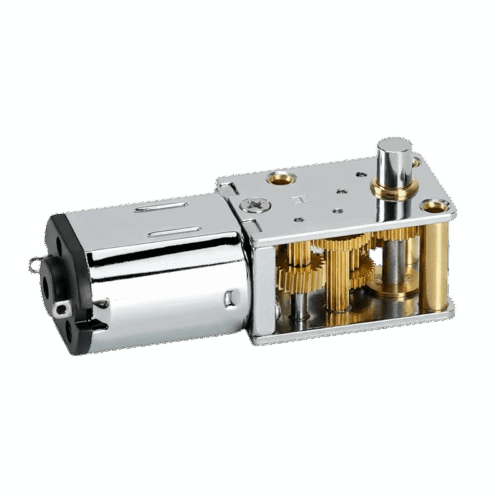

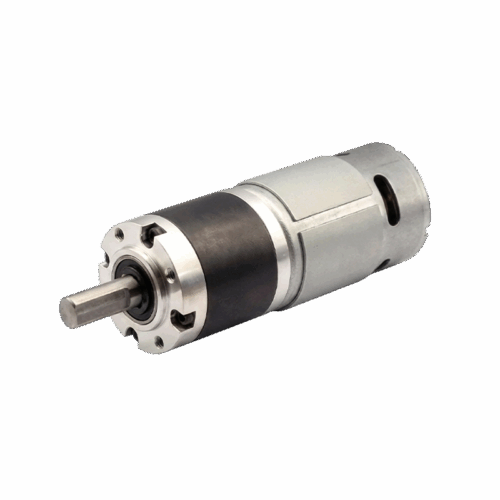

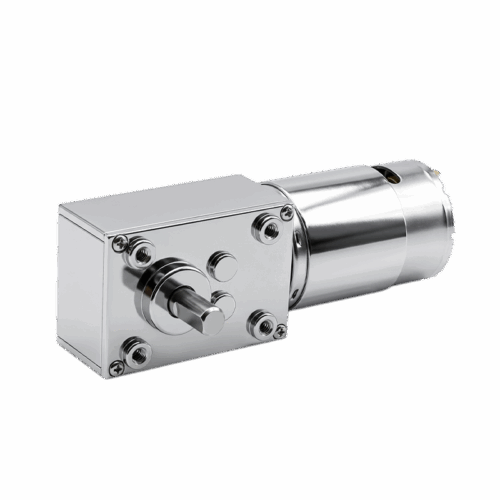

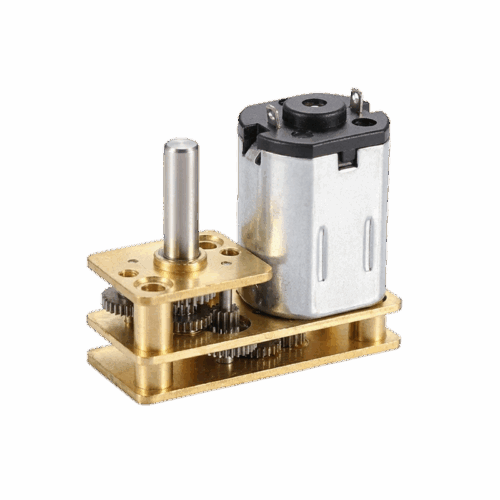

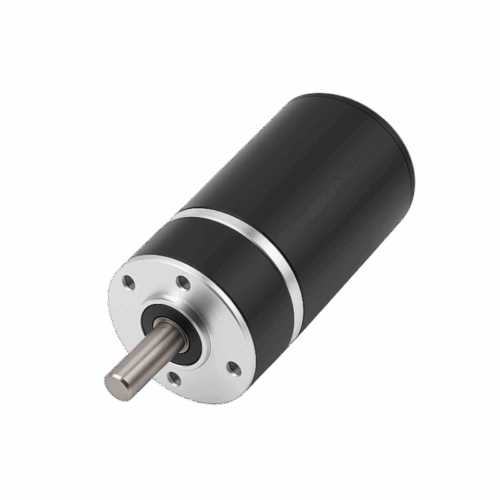

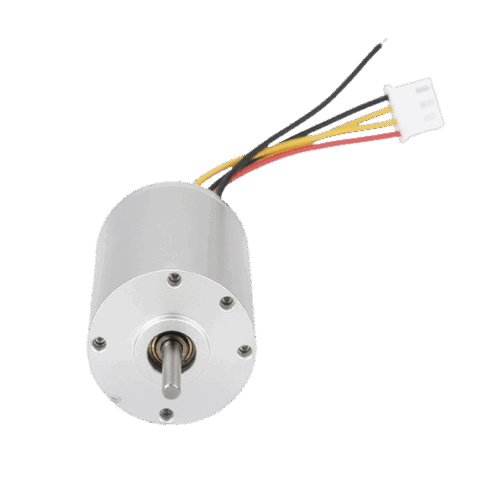

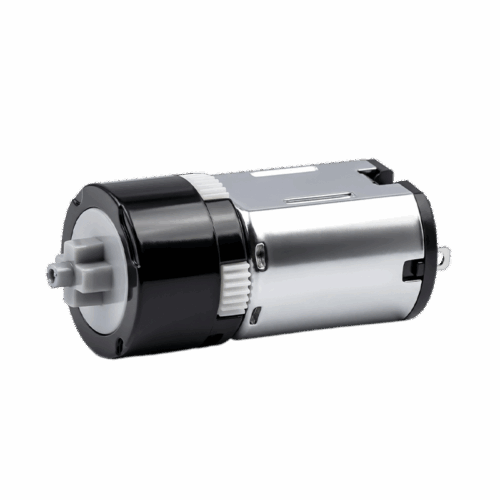

Aerospace and defense systems rely on motion components that deliver absolute reliability, precision, and endurance under extreme conditions. Our miniature motors and gear motors are engineered to perform in high-vibration, high-temperature, and mission-critical environments—making them ideal for avionics, UAVs, targeting systems, and rugged field equipment.