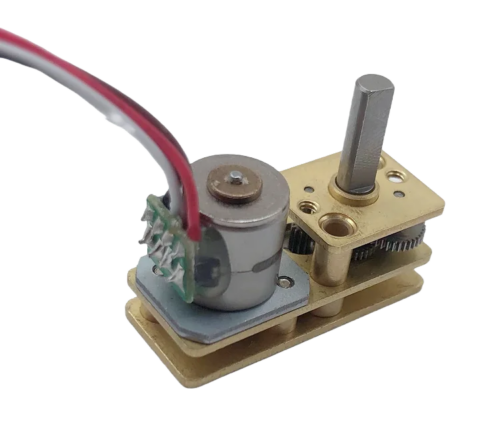

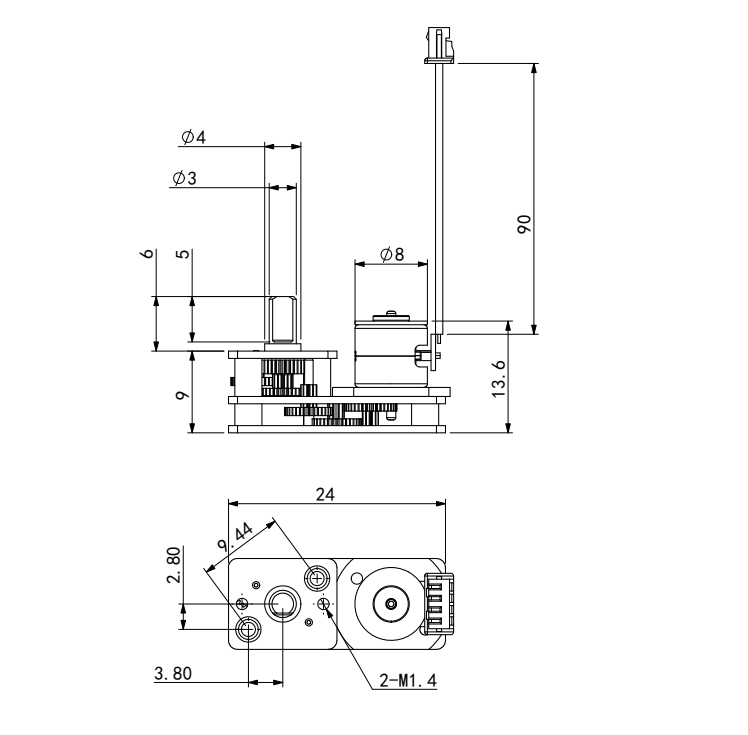

8mm Diameter Stepper Motor With Parallel Output Shaft Gearbox

This 8mm diameter stepper motor with a parallel output shaft gearbox is designed for compact mechanisms where the motor axis must be offset to fit specific layout or transmission paths.

This configuration separates the motor axis from the output shaft, allowing greater flexibility in compact mechanical layouts.

| Reduction ratio | 50 | 110 | 168 | 210 | 250 | 293 | 350 | 380 | |

| Gearbox length | mm | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| Step angle | ° | 0.360 | 0.164 | 0.107 | 0.086 | 0.072 | 0.061 | 0.051 | 0.047 |

| Pull in torque(500pps) | g.cm | 173 | 339 | 517 | 647 | 770 | 902 | 1078 | 1170 |

| Rated speed(500pps) | rpm | 150 | 50 | 30 | 15 | 10 | 7.14 | 6.0 | 5.03 |

For additional customization or reference configurations, please feel free to contact us.

Parallel output configurations are often chosen to solve layout constraints rather than power needs.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.