What Torque & Speed Specs You Must Check Before Buying a Motor

If you're shopping for a motor and staring at a datasheet full of confusing numbers, you're not alone. Most people don't know where to start when comparing torque, speed, and power ratings. Here's what you need to check first: match the motor's continuous torque and rated speed to your application's actual power requirements, then verify the voltage and current specifications fit your power supply.

That's the shortcut. But there's more to it, and the details matter a lot. Let me walk you through everything.

Why These Specs Actually Matter

Before we dive into the numbers, let's be honest about why this matters. Buy the wrong motor, and you're looking at a system that either doesn't work at all or burns out in a few weeks. We've seen equipment manufacturers waste months and money because they misread a single spec.

The good news? Understanding torque and speed is simpler than it sounds. You just need to know what you're looking for.

The Two Numbers You Must Check First

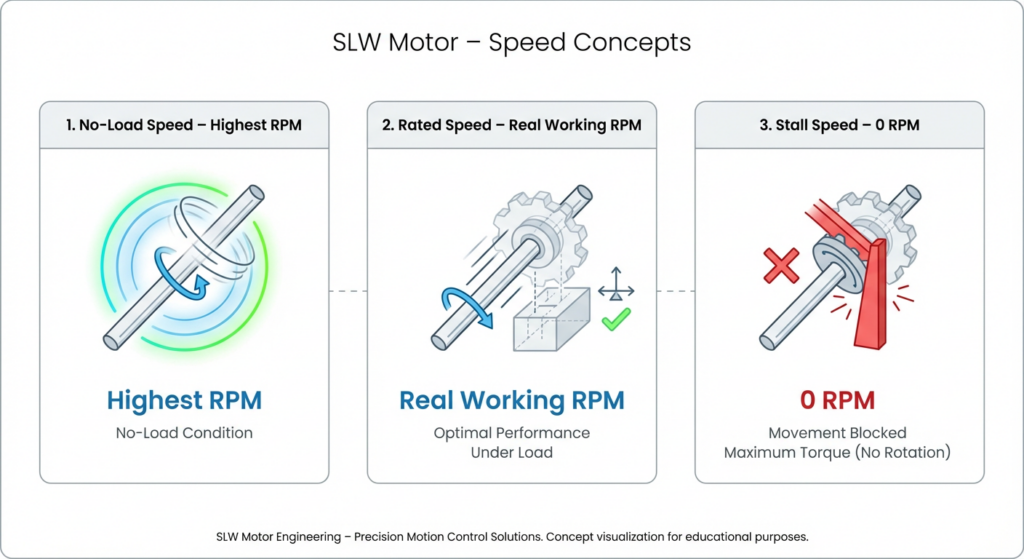

1. Rated Speed (RPM)

Your motor's speed is measured in revolutions per minute, or RPM. This tells you how many times the shaft rotates in 60 seconds.

Here's the practical part: your application has a speed requirement, and your motor must match it. If you need a spindle that rotates at 5,000 RPM, a motor rated for 3,000 RPM won't cut it—literally or figuratively.

Look for the "rated speed" in the datasheet. This is the speed at which the motor operates under normal conditions with rated load applied. It's different from no-load speed (which is higher) or stall speed (which is zero).

Why does this matter? Because motors run most efficiently near their rated speed. Push them far beyond it, and efficiency drops. Run them well below it, and you're wasting power.

Does the motor's rated speed match what your application needs?

If not, stop right there and look for a different motor.

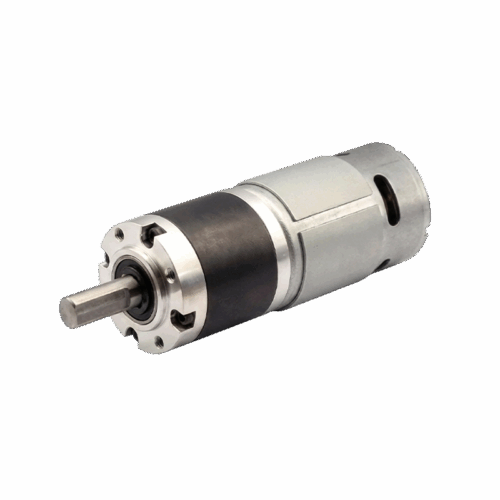

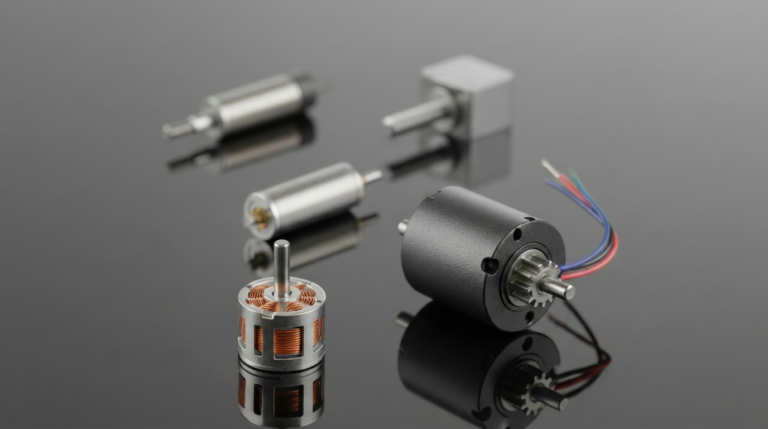

If you're looking for motors designed for higher RPM applications, explore our Brushless DC Motors and Coreless Motors which maintain stable speed under load.

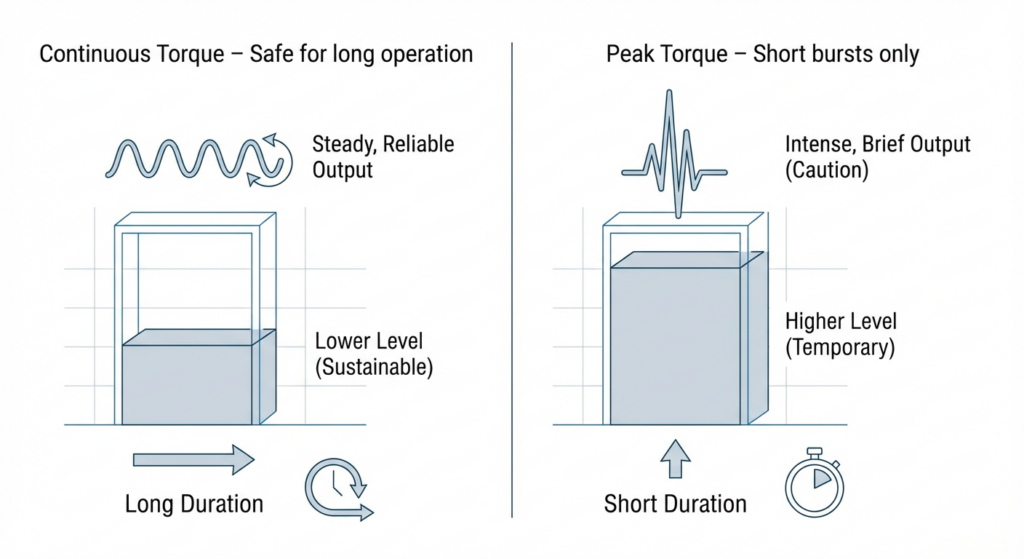

2. Continuous Torque (Rated Torque)

Torque is the rotational force your motor produces. It's measured in units like Newton-meters (Nm), ounce-inches (oz-in), or pound-feet (lb-ft).

Think of it this way: torque is what actually does the work. If speed is how fast something spins, torque is how hard it pushes while spinning.

Look for "continuous rated torque" or sometimes "rated torque" in the specs. This is the maximum torque the motor can deliver continuously without overheating—not just for a second or two, but for as long as you're running it.

Here's the mistake we see often: People confuse peak torque with continuous torque. Peak torque is higher (sometimes much higher), but you can only use it briefly. For real-world applications, you need continuous torque.

Add up all the resistive forces your motor needs to overcome (friction, load, inertia). Your motor's continuous torque should comfortably exceed this total. A good rule of thumb is to have 20-30% more torque capacity than your calculated need.

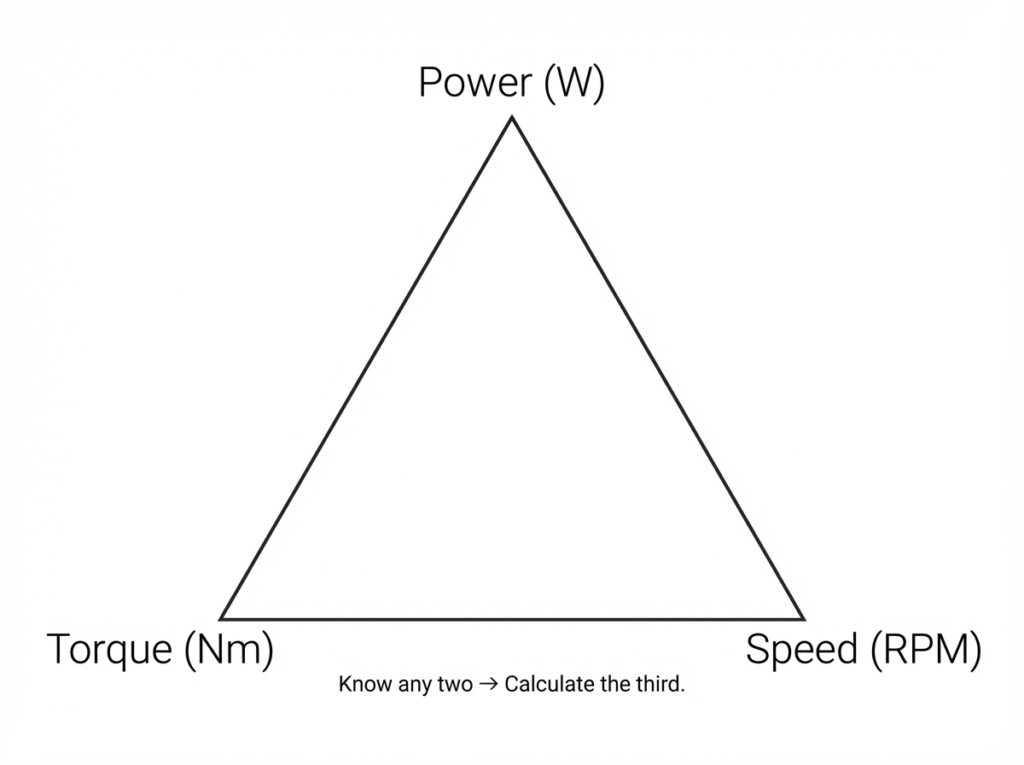

Understanding the Power Triangle

Here's where it clicks together. Three specs form a triangle: speed, torque, and power. If you know two of them, you can calculate the third.

The relationship is:

Power (watts)=Torque (Nm)×Speed (RPM)/9.549

Or more simply:

where P is power, τ is torque, and ω is angular velocity.

Why does this matter? Because you can't arbitrarily increase both speed and torque. If your power supply is limited, increasing one means decreasing the other. A 100-watt motor running at high speed delivers less torque. The same 100-watt motor running at lower speed delivers more torque.

Example: We had a customer who needed 10 Nm at 3,000 RPM. They initially ordered a 200-watt motor. Sounds reasonable, right? But the math showed they actually needed about 3,140 watts. That's a 15x difference. A 200-watt motor would stall under that load.

Always calculate power requirements.

Don't assume.

The Voltage and Current Specs (Don't Overlook These)

Now that you've got speed and torque sorted, check the electrical specs.

Rated Voltage

Your motor needs a power supply that matches its rated voltage. Common options are 6V, 12V, 24V, or higher for industrial applications.

This seems obvious, but here's the trap: higher voltage doesn't mean better. It means different. A 24V motor will cost more to operate than a 12V motor if your facility only has 12V available. You'd need expensive converters.

Check your power supply first. Then choose a motor designed for that voltage.

Rated Current (Continuous)

This tells you how much electrical current (measured in amps) the motor draws when running at rated load and rated speed.

Why matters? Your power supply and wiring must handle this current. If the datasheet says 5 amps continuous, but your power supply can only deliver 3 amps, the motor will either:

- Stall

- Draw more current than the power supply can handle (and shut off)

- Run inefficiently

Also check whether the motor has built-in thermal protection. Some do; some don't. If it doesn't, overheating becomes your problem to solve.

Can your power supply deliver the rated voltage at the rated current? If not, you need a different power supply or a different motor.

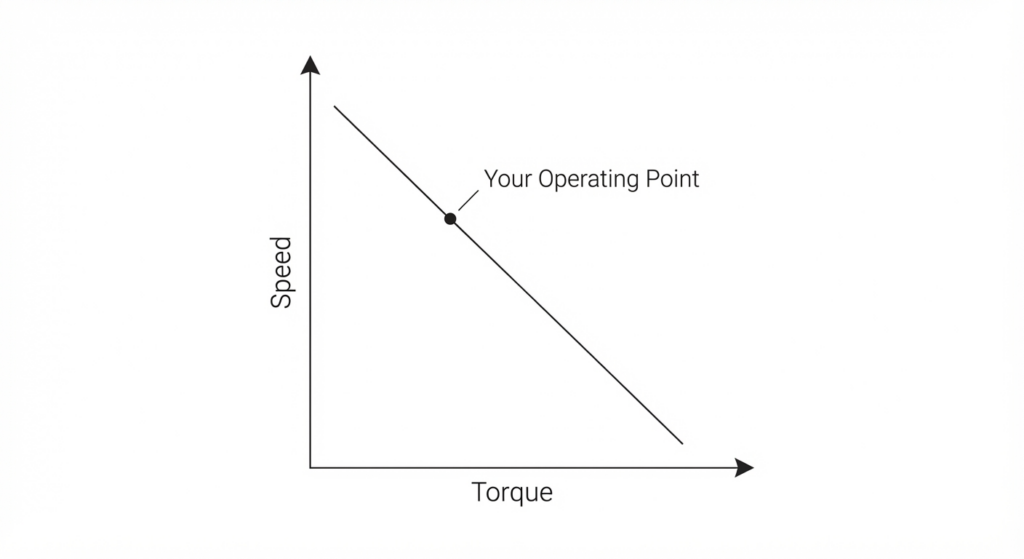

Speed Curves and Load Performance

Here's where datasheets get more sophisticated. The best ones include a speed vs. torque curve (also called a performance curve).

This curve shows you what actually happens when you load the motor. At no load (zero torque), the motor runs at its maximum speed. As you increase the load (increase torque demand), the speed drops. The motor slows down.

This is normal and expected. But the curve shows you exactly how much it slows.

Why care? Because some applications are speed-sensitive. If you're driving a conveyor belt or a spindle, a 10% speed drop might be unacceptable. The curve tells you if it'll happen.

Also, look for where the curve intersects your application's load. That intersection point is your actual operating point—the real speed and torque your motor will deliver with your specific load. It's usually different from the rated specs, and that's okay. Just make sure it's close enough to work for you.

We had a customer who needed exactly 5,000 RPM under full load. They picked a motor rated for 5,000 RPM. Without checking the curve, they assumed they'd get 5,000 RPM. They actually got 4,650 RPM. Close, but not close enough for their application. A different motor with a steeper curve would have held speed better.

Duty Cycle: Continuous vs. Intermittent

Datasheets often specify whether a motor is rated for:

- Continuous duty (runs all day, every day)

- Intermittent duty (runs for short periods, then rests)

- Thermal duty (specific time limits, like 15 minutes on, 15 minutes off)

This directly affects the torque the motor can deliver.

A motor rated for intermittent duty might deliver 20 Nm for 10 minutes, then needs to cool. The same motor's continuous rating might be only 12 Nm because it needs to stay cool indefinitely.

If you use an intermittent-duty motor in a continuous application, it will overheat and fail.

Does the duty cycle in the datasheet match your actual usage?

Learn more about duty-cycle here.

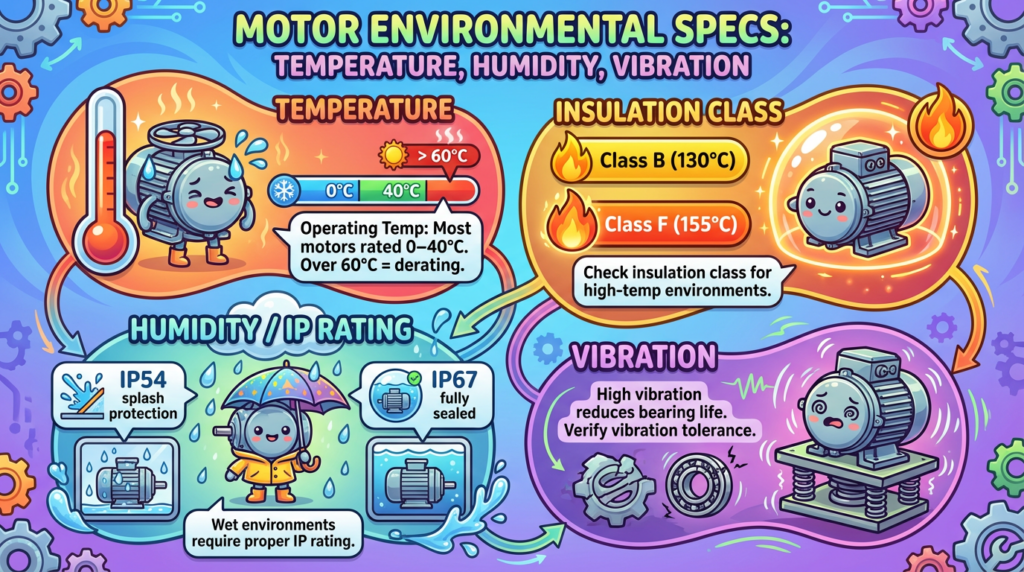

Environmental Specs (Temperature, Humidity, Vibration)

Don't skip these. They matter more than people think.

Operating temperature: Most motors are rated for 0-40°C ambient. If you're operating in a 60°C environment (like next to a furnace), that motor will derate. It'll deliver less power. Or fail sooner.

Insulation class: This tells you the temperature the motor's windings can handle. Class B is standard (130°C). Class F is higher (155°C). If your motor's insulation class doesn't match your environment, derate the specs by 20-30% to be safe.

Humidity and ingress protection: If your motor's in a wet environment, check the IP rating (Ingress Protection). IP54 means decent dust and splash protection. IP67 means sealed against full submersion. IP20 means it's basically open to the air—don't use it in wet environments.

Vibration: High vibration environments degrade bearings faster. Some datasheets specify maximum vibration tolerance. If you're mounting a motor on a vibrating platform, account for this.

Efficiency: A Spec That Saves Money

Many datasheets list efficiency, often as a percentage. This tells you what fraction of electrical power becomes useful mechanical power.

An 80% efficient motor running at 100 watts delivers 80 watts of useful work. The remaining 20 watts becomes heat.

Efficiency matters because:

- It affects your operating cost. A 90% efficient motor costs less to run than a 75% efficient motor over a year.

- It affects heat generation. Less efficient motors need better cooling.

- It correlates with reliability. More efficient designs often have better components.

For long-running applications, pay for the more efficient motor. The extra cost is recouped in energy savings within months.

Mechanical Specs: Bearings, Shaft, and Mounting

These aren't sexy, but they matter for longevity.

Bearing type: Sleeve bearings are cheap and quiet but wear faster. Ball bearings cost more but last longer. For continuous duty, ball bearings are worth it.

Shaft diameter and length: Make sure it fits your coupling or pulley. Oversizing here is cheap insurance against failure.

Mounting: Check that the motor's mounting footprint works in your system. Mismatched mounting holes mean custom brackets and wasted time.

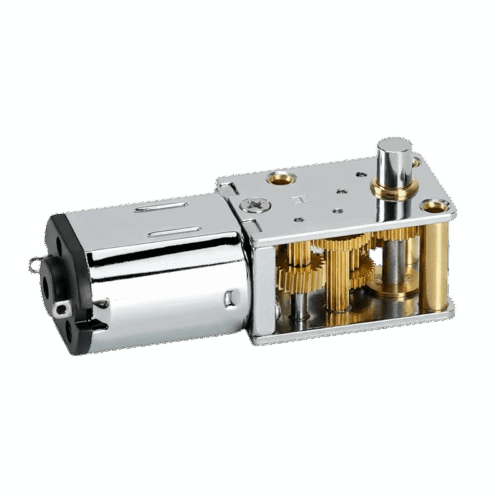

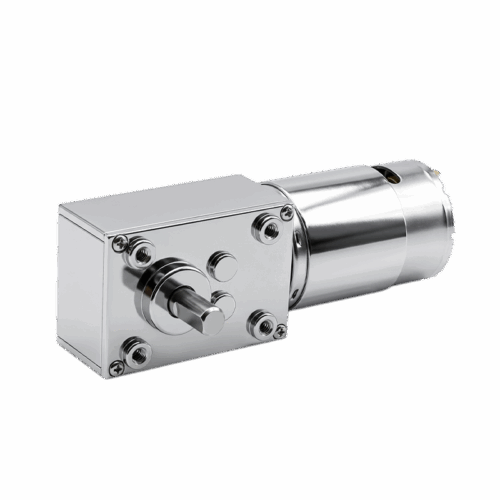

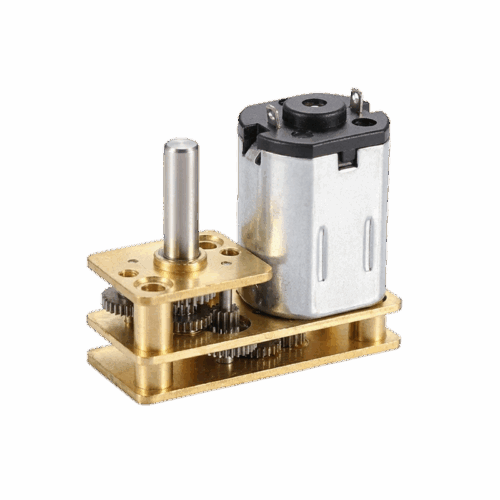

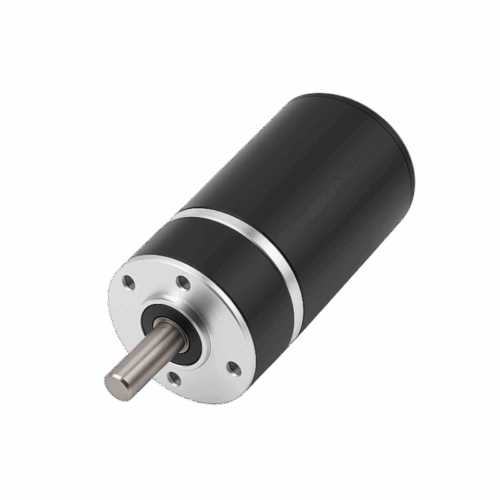

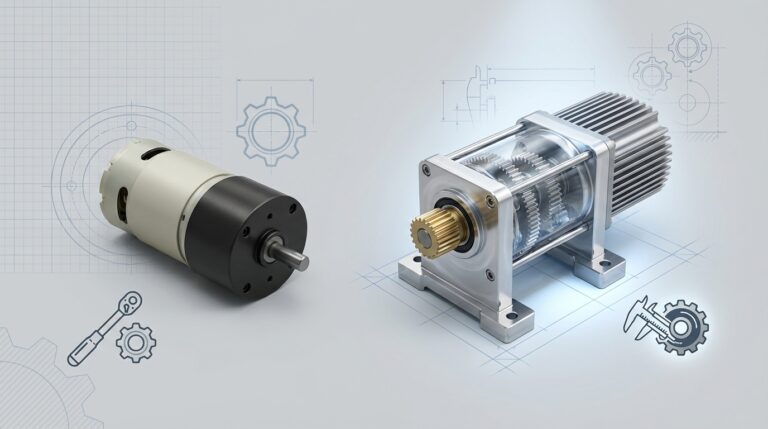

Gearbox (if included): Some motors come with integrated gearboxes. Check the reduction ratio and whether it's sufficient for your torque needs. Gearboxes multiply torque and reduce speed, so a high-speed motor can become low-speed and high-torque.

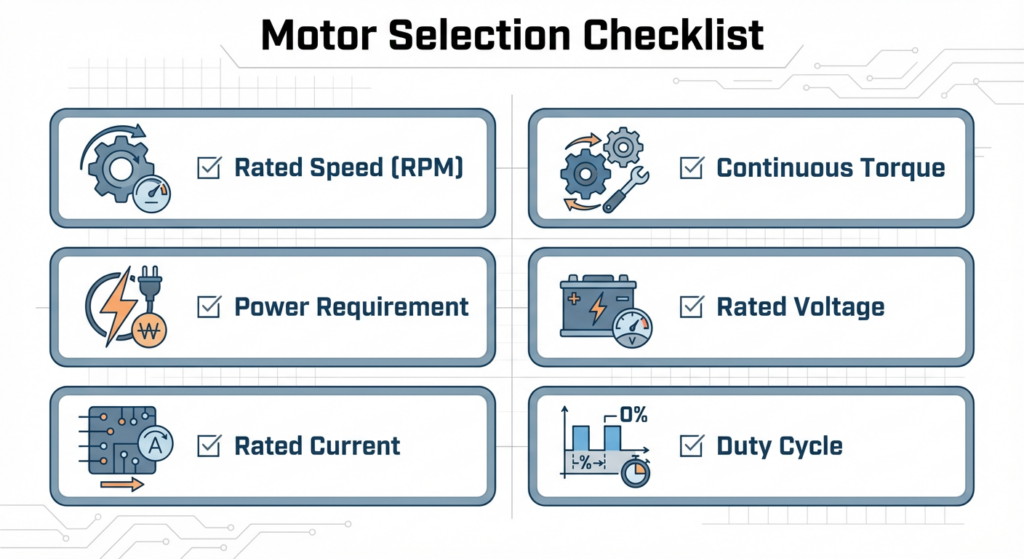

The Checklist: What to Verify Before Buying

Here's a quick reference list. Use this when comparing motors:

- Rated speed (RPM): Matches your application requirement

- Continuous torque: Exceeds your calculated load by 20-30%

- Power: Calculated and verified it's sufficient

- Voltage: Matches your power supply

- Current: Your power supply can deliver it

- Speed-torque curve: Shows acceptable performance at your operating point

- Duty cycle: Matches your actual usage pattern

- Operating temperature range: Suitable for your environment

- Insulation class: Adequate for your temperature

- IP rating: Suitable for moisture/dust exposure

- Bearing type: Appropriate for continuous vs. intermittent use

- Shaft diameter: Compatible with your couplings

- Mounting footprint: Fits your mechanical design

A Real-World Example

Let me show you how this all comes together.

The scenario: A customer needed a motor for a small conveyor system. The conveyor carries 50 kg of product at 0.5 m/s. It needs to run 16 hours a day.

The calculations:

- Required speed: At 0.5 m/s with a 100 mm diameter pulley, that's about 95 RPM needed

- Required torque: 50 kg × 9.81 m/s² × 0.05 m (pulley radius) ÷ reduction ratio. Accounting for friction and a gearbox, about 25 Nm needed

- Power: 25 Nm × 100 RPM ÷ 9.549 ≈ 260 watts

The datasheet hunt:

They found a 24V motor rated for 300 RPM and 15 Nm continuous. On paper, speed was too high and torque was too low. But with a 3:1 gearbox, the motor would deliver 100 RPM and 45 Nm—perfect.

The verification:

- Power at operating point: 45 Nm × 100 RPM ÷ 9.549 ≈ 470 watts (motor oversized, but fine)

- Duty cycle: The motor was rated for continuous duty. They needed 16 hours a day. ✓

- Temperature: Factory was climate-controlled. No issues. ✓

- Power supply: 24V at 20A available. Motor drew about 12A continuous. ✓

They bought the right motor and it ran for three years without issues.

Know Before You Buy

Motor selection isn't mysterious. It's systematic.

Spend 30 minutes understanding these specs, and you'll avoid months of headaches and wasted money.

Start with speed and torque. Verify power. Check the electrical specs. Look at the curve. Consider the environment. Use the checklist. Done.

If you're still unsure about your specific application, reach out to the motor manufacturer.

We're happy to help you find the right fit. After all, our reputation depends on your success.

Get this right from the start, and your equipment will run reliably for years.