Lifting & Material Handling Equipment

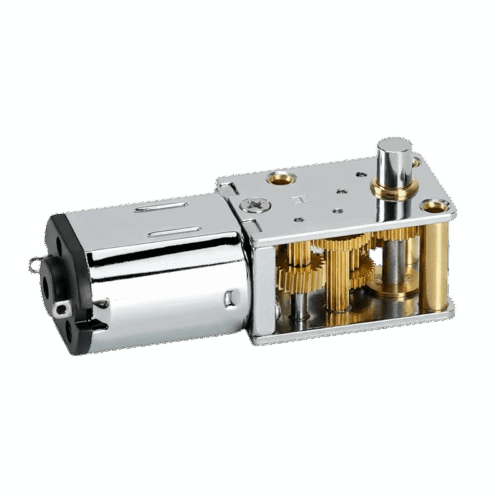

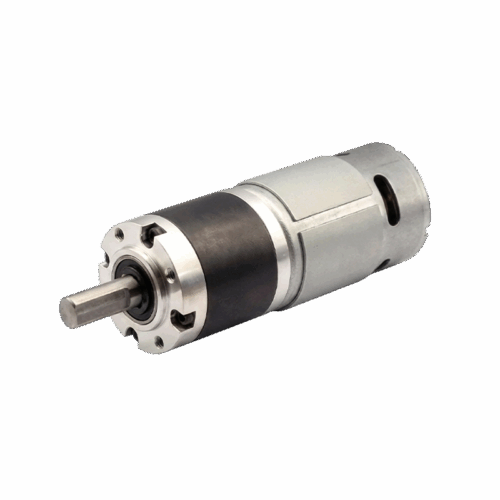

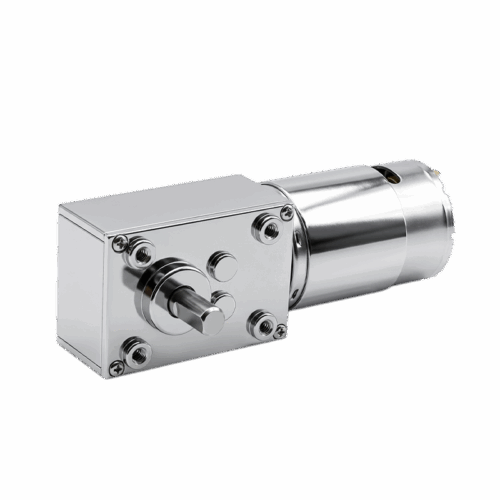

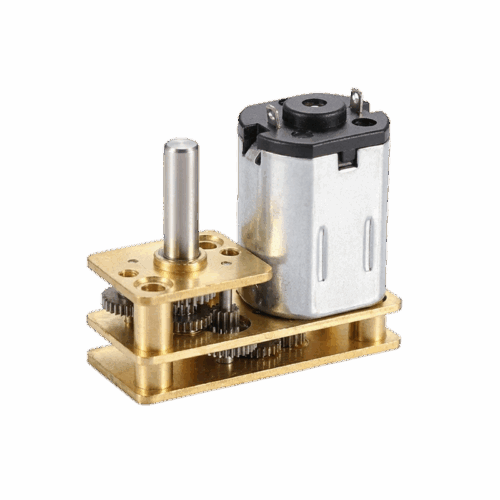

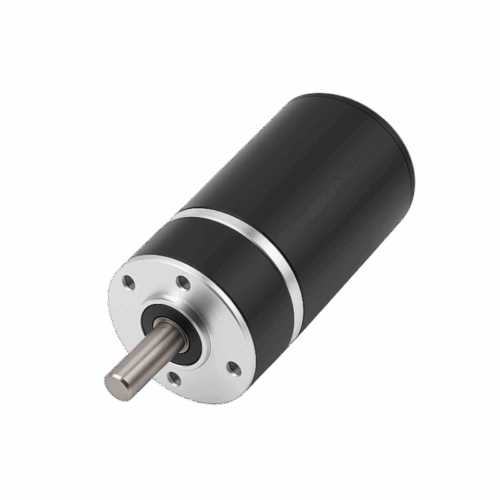

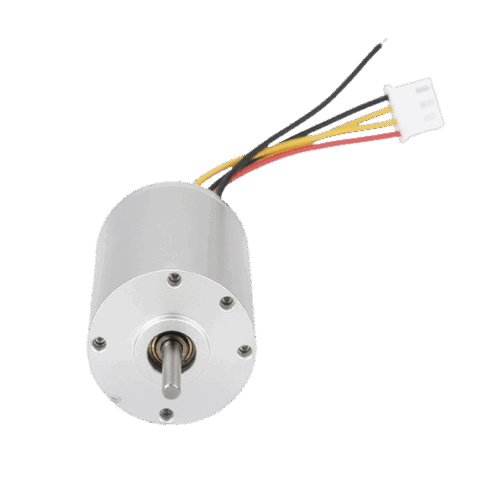

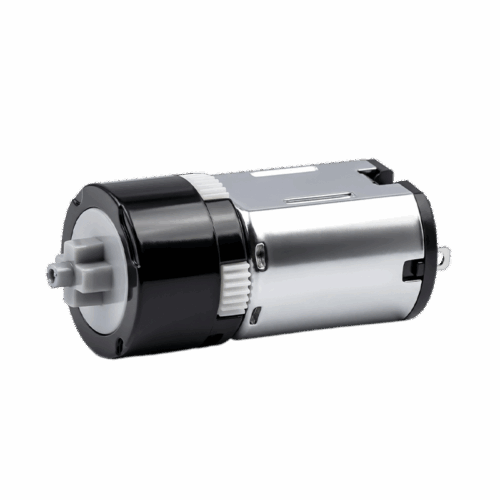

Lifting and material-handling systems require motors that deliver stable torque, precise control, and long service life under continuous or heavy load conditions. Our miniature motors and gear motors provide reliable, efficient motion for hoisting, positioning, conveying, and automated handling equipment across industrial and commercial environments.