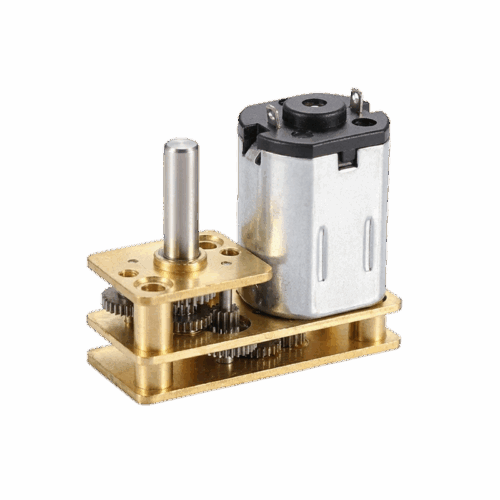

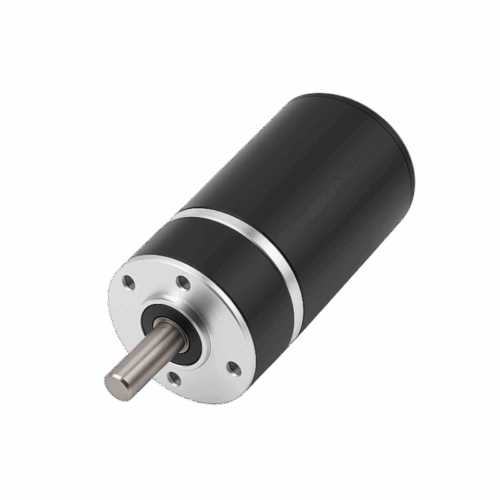

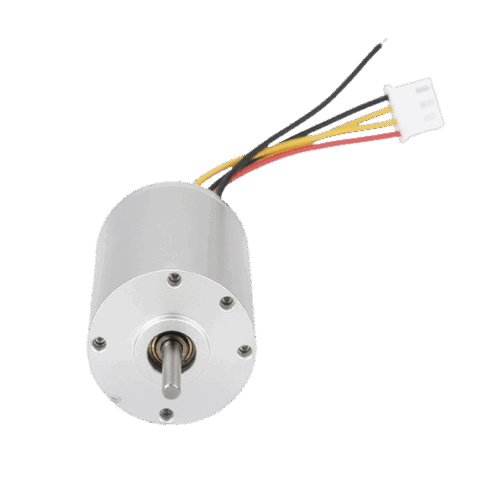

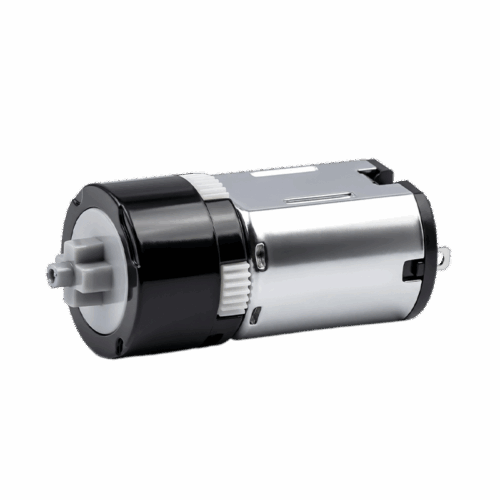

Automotive component

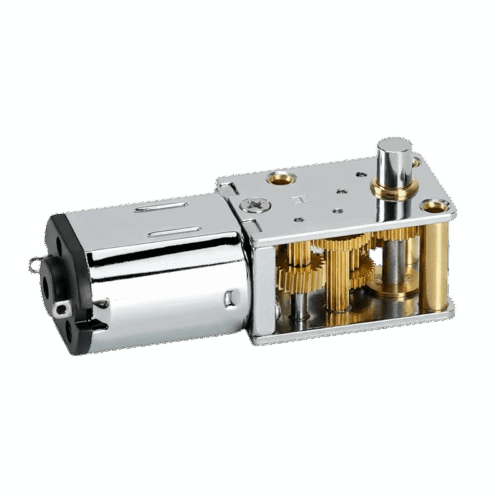

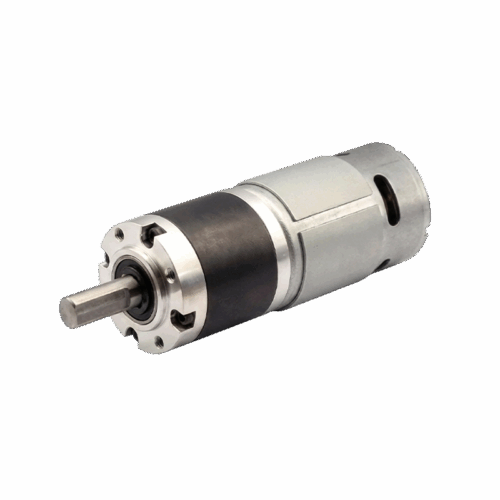

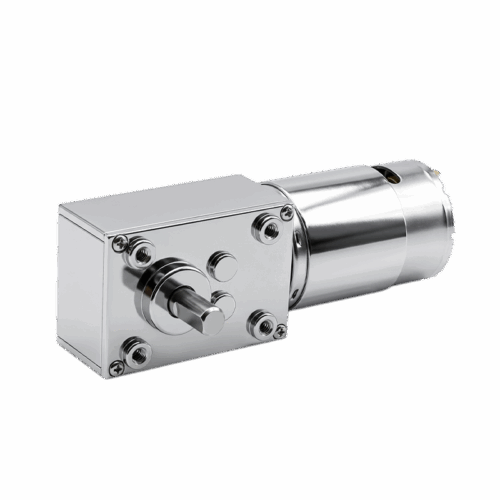

Automotive systems require motion solutions that are compact, durable, and capable of operating reliably under vibration, temperature changes, and continuous duty. Our miniature motors and gear motors power a variety of automotive mechanisms where precision, longevity, and rugged performance are essential.