How Mini Gear Motors Power Everyday Devices You Didn’t Notice

You wake up in the morning, and your alarm goes off. You get up, brush your teeth, grab a cup of coffee, and head out the door. Seems like an ordinary day, right? But what if I told you that micro gear motors are quietly working behind the scenes in nearly every single one of those activities? From the vibration in your smartphone to the mechanisms in your electric toothbrush, these tiny powerhouses are everywhere—and most people have absolutely no idea they exist.

The Hidden Revolution in Your Pocket

Here's the thing about mini gear motors: they've become so integrated into our daily lives that we literally don't think about them anymore.

They're not flashy. They don't get the attention that a smartphone screen or a laptop processor gets. But without them, modern convenience as we know it would simply cease to exist.

When you pull your smartphone out of your pocket and unlock it with facial recognition, there's a motor working. When your electric toothbrush vibrates against your teeth, that's a motor. When your car's window rolls up with the press of a button, when your garage door opens automatically, when your printer ejects paper, when your camera focuses its lens automatically—all of these devices rely on mini gear motors to function.

Gear motors are the unsung heroes of modern consumer electronics.

What Exactly Is a Mini Gear Motor?

Before we dive deeper into where these motors show up in everyday life, let's clarify what we're actually talking about.

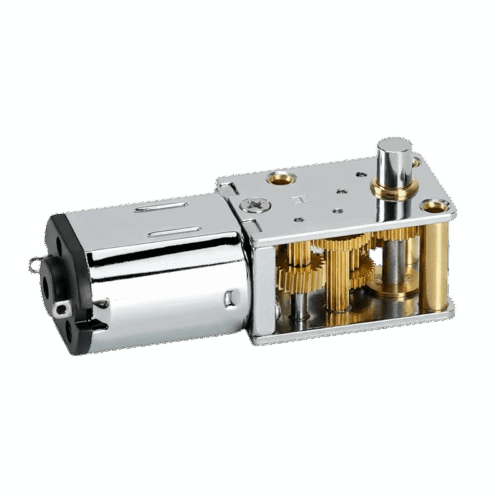

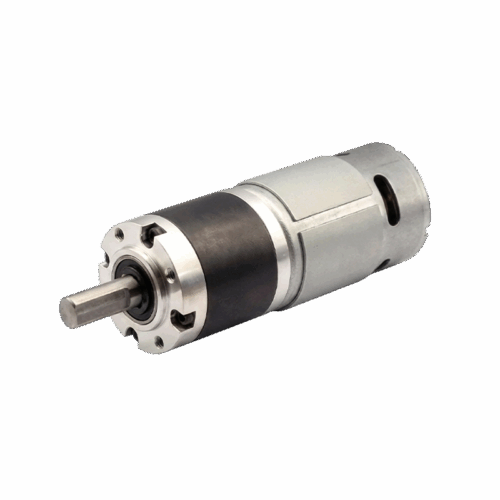

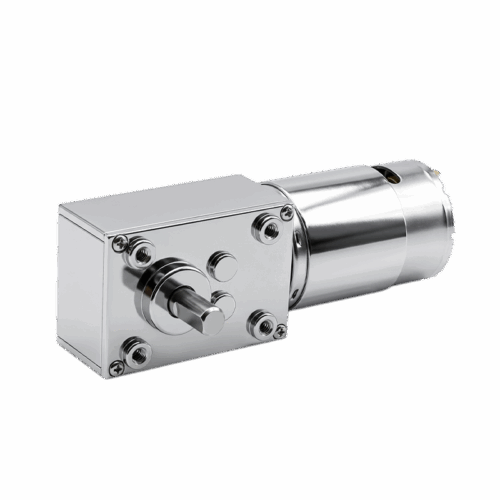

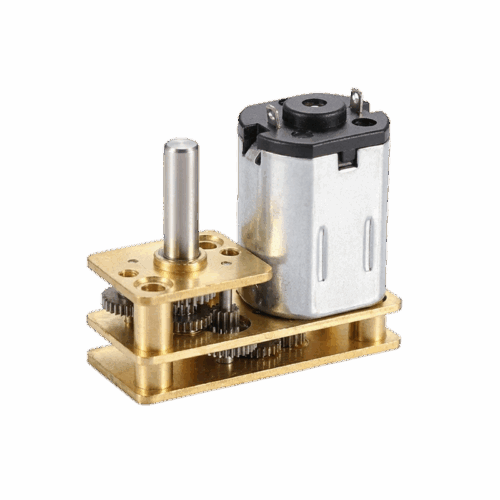

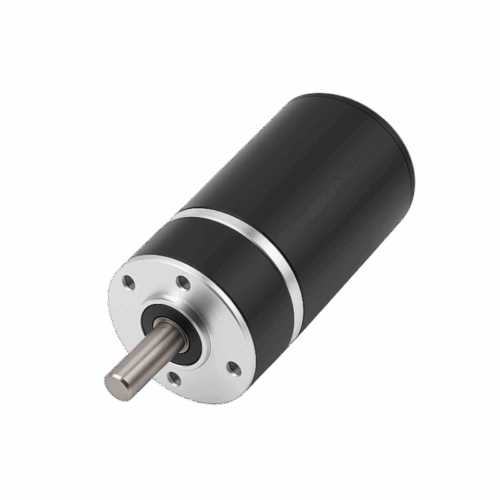

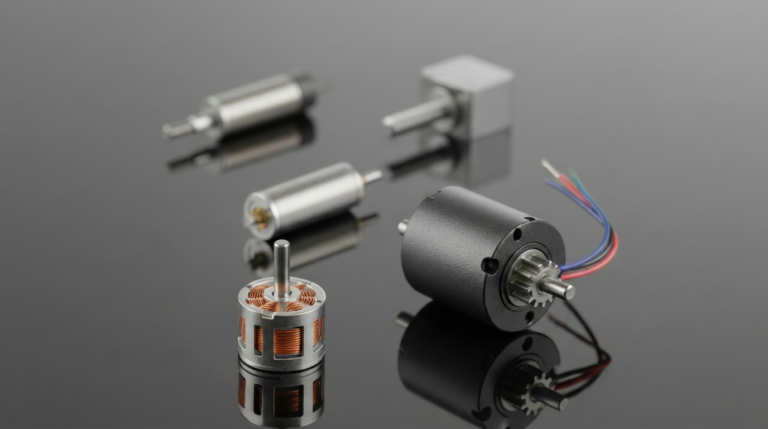

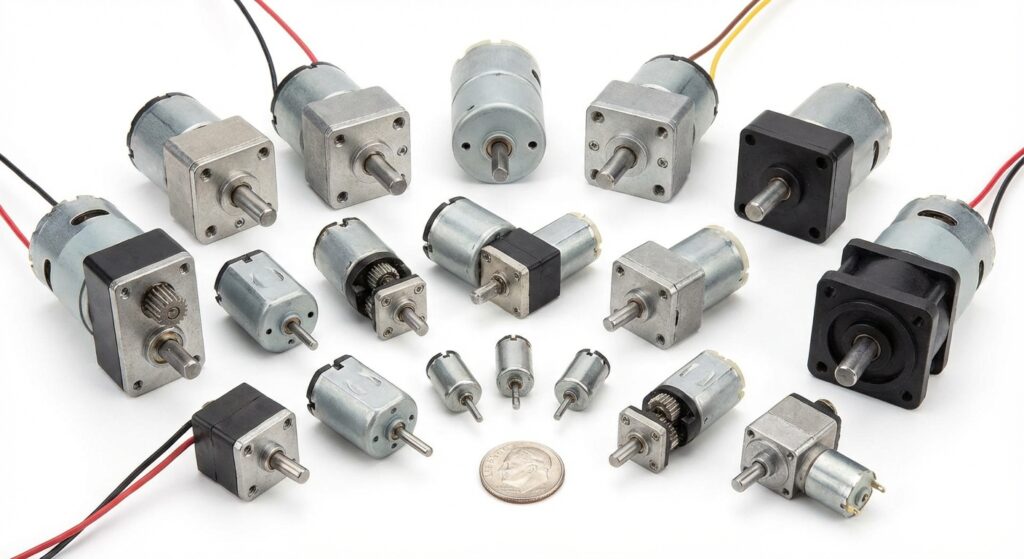

It looks like this:

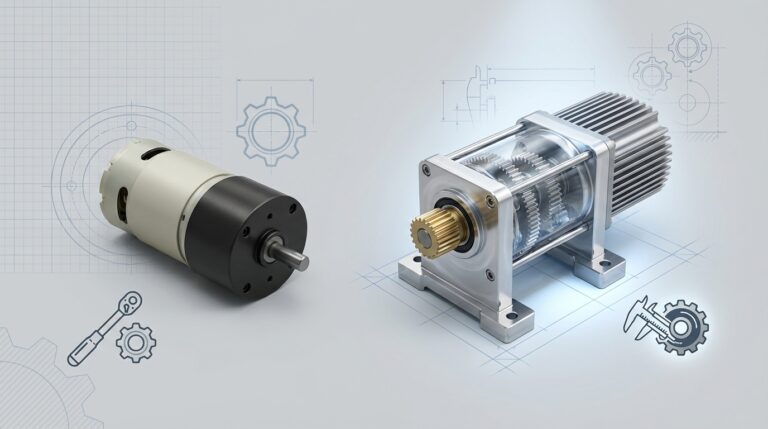

A mini gear motor is a compact electric motor combined with a gearbox. The motor itself converts electrical energy into mechanical rotation, but here's the crucial part—the gearbox does something incredibly important. It reduces the speed of rotation while simultaneously increasing the torque (rotational force). This is why gear motors are so valuable: they give you powerful, controlled motion in a tiny package.

For a deeper technical overview of DC and DC gear motors, you can refer to this introductory guide from Wevolver.

At SLW Motor, we manufacture several types of mini gear motors:

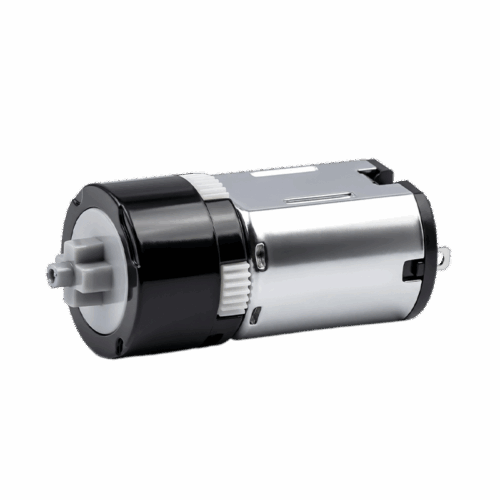

- Brushed DC Gear Motors – Classic, reliable, and ideal for simple, cost-effective motion needs

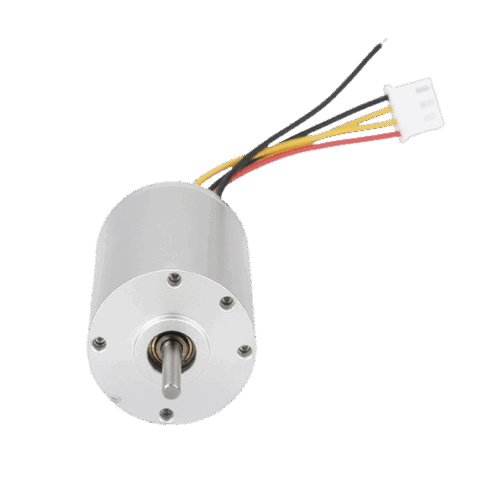

- Brushless DC Gear Motors – High efficiency, low noise, and extended service life for demanding applications

- Coreless Gear Motors – Ultra-lightweight, low inertia, and minimal cogging for smooth precision movement

- Spur Gear Motors – Compact, affordable, and optimized for moderate torque with high efficiency

- Planetary Gear Motors – High torque density, excellent durability, and ideal for heavy-load applications

- Worm Gear Motors – High reduction ratios, quiet operation, and self-locking capability for safety-critical use

- Stepper Gear Motors – Precise incremental motion, great for positioning and automated control systems

The beauty of combining a motor with a gearbox is that it allows engineers to use smaller motors while still achieving the mechanical power needed for their applications. This is why you can pack serious functionality into devices small enough to fit in your hand.

Where Are These Motors Actually Hiding?

Let me take you through your day and show you exactly where mini gear motors are at work.

Your Morning Routine

Electric Toothbrush: This is probably the most obvious one, but it's worth mentioning. That familiar buzzing sensation? That's a brushless gear motor vibrating at around 20,000 to 40,000 times per minute. The gear mechanism helps control and optimize that vibration for cleaning effectiveness. Without the gearbox, the motor would spin too fast and wouldn't produce the right kind of motion.

Electric Razor: Similar principle to the toothbrush, but different execution. The gear motor here drives oscillating blades that give you a clean shave. The gearbox ensures the motion is controlled and consistent.

Hair Dryer: This one uses a slightly larger brushed DC motor to spin a fan that pushes air. While hair dryers might seem too simple to need a gearbox, many modern models include motor speed reduction for efficiency and better heat management.

Leaving Your Home

Garage Door Opener: Here's where mini gear motors really shine. A relatively small motor combined with a gearbox can lift a 300-pound door effortlessly. The gearbox multiplies the torque, allowing a compact motor to do heavy lifting. This is engineering elegance at its finest.

Car Windows and Locks: Remember when you had to roll your windows down manually? Now a small brushless DC gear motor handles it with a single button press. The gearbox reduces speed while increasing torque, giving you smooth, controlled window movement.

Power Steering and Seat Adjustments: Your car contains dozens of mini gear motors. Adjusting your seat, moving mirrors, opening trunk latches—all of these rely on small, efficient motors.

During Your Day

Smartphone Haptic Feedback: When your phone buzzes to alert you or provides haptic feedback during gaming, that's a specialized brushless coreless gear motor doing the job. These motors are incredibly small, sometimes just a few millimeters in diameter, yet they pack enough punch to create that distinctive vibration you feel.

Camera Autofocus: Whether it's in your smartphone, DSLR, or security camera, autofocus systems use tiny stepper motors (a specialized type of gear motor) to move lens elements in and out, creating sharp images instantly.

Printer Paper Feed Mechanism: Every time your printer smoothly feeds paper, that's a gear motor at work. The gearbox ensures precise, consistent paper movement without slipping or jamming.

Coffee Machine: Automatic coffee makers use gear motors to control water flow, pump mechanisms, and heating element adjustments. The precision and reliability of these motors are crucial for that perfect cup of coffee.

In Your Entertainment

DVD/Blu-ray Players: The motor that spins your disc at precisely the right speed to read data is a brushless DC motor. The gearbox helps achieve the exact rotational speeds needed for data retrieval.

Game Controllers: Rumble and vibration effects in modern gaming controllers use micro gear motors. The precision control allows game developers to create incredibly detailed haptic feedback that makes gaming more immersive.

Camera Zoom Mechanism: Whether it's in a digital camera, webcam, or security system, zoom functions rely on gear motors to move lens elements smoothly and accurately.

Around Your Home

Smart Door Locks: These increasingly popular security devices use brushless DC gear motors to throw and retract bolts. The gearbox provides the mechanical advantage needed to operate smoothly and silently.

Robotic Vacuum Cleaners: Multiple mini gear motors power the wheels, the brush system, and the suction mechanism. These motors need to be efficient because they run on battery power.

Electric Curtain Rods: Motorized window treatments use gear motors to open and close smoothly and quietly, often controllable via smartphone.

Automatic Pet Feeders: Those convenient devices that dispense food at scheduled times? Gear motors control the feeder mechanism.

Why Gear Motors Are Perfect for These Applications

You might wonder why gear motors are so ubiquitous. The answer comes down to fundamental physics and practical engineering.

Torque Multiplication

A mini gear motor's primary superpower is torque multiplication. When you combine a DC motor with a gearbox, the gearbox can increase the torque output by a factor of 10, 100, or even more, depending on the gear ratio. This means a small, lightweight motor can operate heavy mechanisms that would otherwise require a much larger motor.

Space and Weight Efficiency

Modern devices are obsessed with being compact and lightweight. A gear motor allows engineers to achieve powerful mechanical output while keeping the overall package small. This is why your smartphone can have haptic feedback without being bulkier, and why a garage door opener doesn't need to be the size of a refrigerator.

Speed Control

Most DC motors spin very fast—sometimes thousands of RPM (revolutions per minute). That raw speed is rarely useful directly. The gearbox reduces speed to useful levels while maintaining or increasing torque. A brushless DC motor spinning at 5,000 RPM might be reduced to 50 RPM by a gear ratio of 100:1, making it practical for countless applications.

Energy Efficiency

Brushless DC gear motors in particular offer excellent energy efficiency. This matters enormously for battery-powered devices. An electric toothbrush running on a brushless motor can operate for two weeks on a single charge, whereas older brushed versions might only last a few days. The efficiency advantage translates directly to consumer convenience.

Learn more How Electric Toothbrush Works?.

Precision and Control

Gear motors offer predictable, repeatable performance. This precision is essential for applications where accuracy matters—like camera autofocus, printer paper feed, or robotic systems.

The Technology Behind Modern Gear Motors

The mini gear motors you'll find in modern devices are far more sophisticated than the motors of just a decade ago.

Brushless Technology

Brushless DC (BLDC) motors have become increasingly popular because they eliminate the carbon brushes that require maintenance and eventually wear out. Brushless motors use electronic commutation instead, making them:

- More efficient (often 85-95% efficient)

- Quieter

- More reliable

- Longer-lasting

- Better suited for precision applications

Coreless Motor Design

Coreless motors eliminate the iron core from the rotor, creating several advantages:

- Reduced cogging: The motor produces smoother motion with less vibration

- Faster acceleration: Less rotational inertia means quicker response

- Lower electromagnetic interference: Better for sensitive electronic devices

- Lighter weight: Important for portable devices

Smart Motor Control

Modern gear motors often include integrated electronics that allow for:

- Speed regulation: Maintaining consistent output regardless of load changes

- Direction control: Easy switching between forward and reverse

- Soft start: Reducing mechanical stress during startup

- Current limiting: Protecting the motor and power source

Looking Forward: The Future of Mini Gear Motors

The evolution of mini gear motor technology isn't slowing down. Manufacturers like SLW Motor are constantly innovating to meet the demands of emerging technologies.

IoT and Smart Home Integration

As more devices become "smart" and connected, gear motors need to be more efficient, more controllable, and more reliable. We're seeing development of micro-motors optimized for IoT devices that run on minimal power and can be controlled remotely.

Electric Vehicle Components

As electric vehicles become mainstream, demand for compact, efficient gear motors for window lifts, seat adjustments, and climate control systems continues to grow. These motors need to meet automotive-grade reliability standards.

Robotics and Automation

The robotics revolution demands increasingly sophisticated motor control. Mini gear motors are becoming more intelligent, with integrated sensors and digital communication capabilities.

Medical Devices

Portable medical devices, from nebulizers to infusion pumps, rely on mini gear motors. Innovation in this space focuses on reliability, precision, and miniaturization.

The Bottom Line

The next time you use an electric toothbrush, adjust your car window, or feel the vibration of your smartphone, take a moment to appreciate the mini gear motor doing the work. These tiny machines represent the convergence of electric motor technology, precision engineering, and practical design—all working together to make your life more convenient.

At SLW Motor, we're proud to manufacture the gear motors that power these everyday innovations. Whether it's a brushless DC motor for a premium toothbrush, a brushed motor for an automotive application, or a coreless motor for precision electronics, we're committed to providing the highest quality motors that power the devices you use every single day.

The revolution in modern convenience isn't happening on a screen or in the cloud—it's happening in the tiny gear motors hidden inside the devices around you. And honestly? That's pretty remarkable.