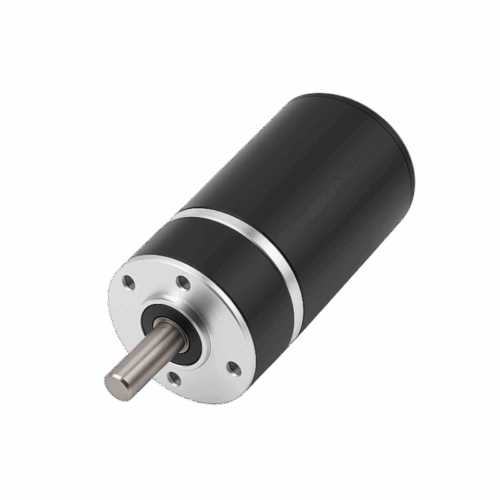

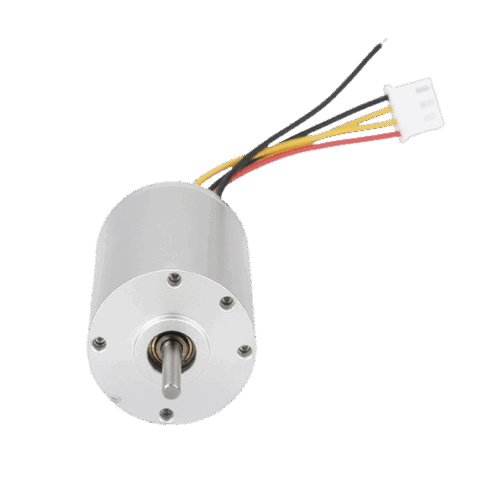

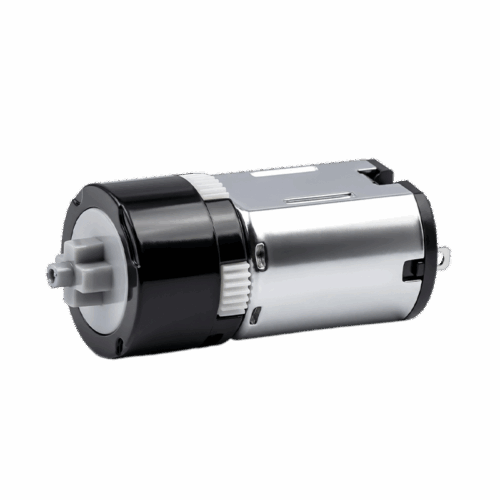

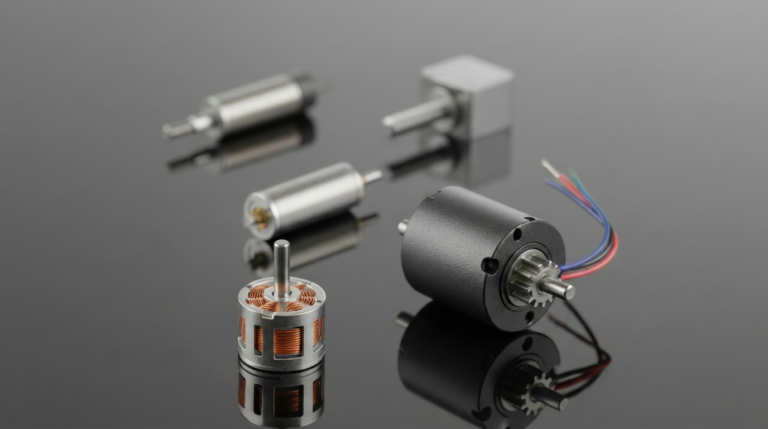

How to Extend the Lifespan of Your DC Gear Motor

When you invest in a DC gear motor, you're investing in reliability and performance. But here's the reality: like any mechanical component, DC gear motors have a finite lifespan—unless you know how to properly maintain them.

The good news? You don't need to redesign your equipment or overhaul your entire system. Small, deliberate actions taken today can add years of productive life to your motors.

At SLW Motor, we work with customers who face the same challenge week after week: their motors are wearing out faster than expected, and they're looking for ways to extend the motor lifespan without major redesigns or costly equipment replacements.

That's why we've put together this comprehensive guide based on decades of industry experience.

| Maintenance Area | Impact on Lifespan | Why It Matters | What to Do |

|---|---|---|---|

| Lubrication | ⭐⭐⭐⭐⭐ | Reduces wear, heat, friction | Choose correct oil, follow schedule |

| Contamination Control | ⭐⭐⭐⭐ | Dust/moisture cause accelerated wear | Improve seals, covers, environment |

| Temperature Management | ⭐⭐⭐⭐ | Heat cuts insulation life in half every +10°C | Monitor heat, improve airflow |

| Load & Alignment | ⭐⭐⭐ | Misalignment causes vibration & bearing damage | Align couplings, secure mounts |

| Electrical Parameters | ⭐⭐⭐ | Voltage/current deviations overstress the motor | Keep within ±10%, quality supply |

| Storage Practices | ⭐⭐ | Idle motors corrode and degrade | Protect from moisture, check before restart |

Most Motor Failures Are Preventable

Before we dive into specific strategies, let's address something important. Studies show that up to 80% of premature motor failures stem from maintenance issues rather than manufacturing defects. This is actually great news for you—it means the power to extend your motor's life is largely in your hands.

The most common culprits?

- Poor lubrication,

- Inadequate cooling,

- Dust and contamination,

- Misalignment,

- Operating conditions that exceed design specifications.

The encouraging part is that each of these can be addressed with straightforward practices that fit into your existing operations.

The Most Critical Factor: Lubrication

If there's one thing that will single-handedly extend your DC gear motor's lifespan, it's proper lubrication. Think of lubrication as the lifeblood of your motor. Without it, you're operating on borrowed time.

Why Lubrication Matters

Inside your gear motor, metal components are in constant contact. At the microscopic level, even "smooth" surfaces have peaks and valleys. Without proper lubrication, these surfaces grind against each other, generating:

- Excessive friction that converts energy into wasted heat

- Metal-to-metal wear that progressively damages teeth and bearing surfaces

- Heat buildup that accelerates degradation of insulation materials

- Corrosion when moisture finds its way into unprotected areas

With proper lubrication, you create a protective film that separates these surfaces, reducing wear rates by up to 10 times.

What You Need to Know About Lubricant Selection

Not all lubricants are created equal. Here's what matters:

Viscosity Grade: This is the lubrication oil's thickness. For most DC gear motors, ISO VG 32 to VG 68 is appropriate, though you should always consult your motor's specifications. The right viscosity ensures that the oil flows properly while maintaining enough body to protect components at operating temperature.

Type Selection: Consider whether your motor requires:

- Mineral oils (standard choice, cost-effective)

- Synthetic oils (better at extreme temperatures, longer service life)

- Biodegradable options (increasingly important for environmentally sensitive applications)

Additives: Modern lubricants include anti-wear agents, oxidation inhibitors, and corrosion preventatives. These aren't luxuries—they're protection for your investment.

Lubrication Schedule and Best Practices

The frequency of lubrication depends on your specific motor and operating conditions, but here's a practical framework:

For sealed DC gear motors: Check the oil level every 2,000 operating hours or quarterly, whichever comes first. Top up if necessary, but never overfill—excess lubricant can cause drag and overheating.

For open-design motors: More frequent attention is needed. In dusty environments, monthly checks are appropriate. In clean environments, quarterly checks usually suffice.

During lubrication:

- Allow the motor to cool before checking oil levels

- Use a clean rag or funnel to prevent contamination

- Keep the lubricant container sealed and clean

- Document your maintenance—it's your proof of proper care

Keeping Contaminants Out

Imagine if your motor had to process air filled with microscopic particles every second of operation. That's what happens when contamination sneaks in. Dust, moisture, and debris act like sandpaper inside your motor, accelerating wear astronomically.

How lubricant contamination leads to wear and premature failures.

Common Contamination Sources

Environmental dust and particles: These are the obvious culprit. Motors operating in manufacturing environments, warehouses, or outdoors face continuous exposure.

Moisture: Humidity and condensation are sneaky enemies. They cause corrosion on bearing races and gear teeth, particularly damaging during storage or in seasonal applications.

Wear debris: As components age slightly, small metal particles circulate in the lubricant. Left unchecked, this wear debris accelerates damage to other components.

Seal degradation: Aging seals lose their effectiveness, allowing contamination ingress while letting lubricant leak out.

Practical Contamination Control Strategies

Upgrade your seals: If your motor uses basic felt seals, consider consulting with us about upgrading to double-lip seals or labyrinth designs. Better seals keep more contamination out without requiring motor redesign.

Install protective covers: If your motor installation includes exposed areas, simple protective covers (breathable ones that allow moisture to escape) can reduce dust ingress by 70-90%.

Maintain environmental cleanliness: This seems obvious, but regular cleaning of the area around your motors pays dividends. Reduce dust, manage moisture (proper ventilation and dehumidification), and keep spillage away from motor vents.

Monitor oil cleanliness: If your motor has a sight glass, you're already checking oil levels—also check clarity. Clean oil should appear transparent or slightly amber-colored. If it's turning dark or you see particles, it's time for an oil change.

Temperature Management

Every 10°C increase in operating temperature roughly halves the expected lifespan of motor insulation materials. That's not a minor detail—it's often the difference between a motor that lasts three years and one that lasts ten.

NEMA insulation classes (A, B, F, H) and temperature limits.

Understanding Your Motor's Temperature Limits

DC motors have thermal limits, typically expressed as temperature classes (like Class F = 155°C or Class H = 180°C). But here's what many operators don't realize: just because your motor can handle these temperatures doesn't mean it should operate at them continuously.

Designing for continuous operation 20-30°C below the motor's maximum class rating adds years of life.

Practical Cooling Strategies

Ensure adequate airflow: Never cover motor ventilation ports. In enclosed spaces, consider adding a small fan near the motor to improve ambient air circulation.

Monitor ambient temperature: If your operating environment is hotter than the design specification (typically assumed to be 40°C), the effective lifespan decreases. In hot environments, consider:

- Scheduling heavy loads during cooler hours

- Adding localized cooling (a small fan directing air at the motor)

- Installing thermal monitoring if the application is critical

Reduce mechanical load where possible: Lower load means lower current draw, which means less heat generation. Even small reductions in load have compounding benefits over time.

Check bearing condition: Worn bearings increase friction and heat. Proper bearing maintenance is actually a temperature management tool.

Operating Within Design Specifications

Your motor was designed to operate at specific voltage, current, and frequency parameters. Operating outside these parameters is like running an engine with the wrong fuel—you might get away with it once or twice, but long-term, you're asking for trouble.

Voltage Considerations

Voltage variations: Operating at significantly higher or lower voltage than rated creates problems:

- Low voltage causes excessive current draw (more heat, more wear on brushes and commutator in brushed motors)

- High voltage increases stress on insulation and can accelerate degradation

Keep voltage within ±10% of rated specification. If your facility has voltage instability, a voltage regulator is a small investment that pays major dividends.

Power supply quality: If you're using PWM (Pulse Width Modulation) control, harmonics can create additional heat. Quality power supply design matters.

Current Overload Scenarios

Motors performing beyond their rated capacity generate excess heat and stress. That task your motor "almost" handles? That's where problems start. Better to downsize the task or upgrade the motor than to run constant overload.

Addressing Mechanical Alignment and Load Issues

Misalignment between motor and load creates vibration, which creates multiple problems: accelerated bearing wear, increased friction, heat generation, and potential seal damage.

Simple Alignment Checks

Coupling alignment: For motors with couplings, ensure axial and angular alignment. A 0.5mm misalignment might seem minor—until you calculate the effects over millions of rotations.

Mount security: Vibration increases dramatically if the motor isn't securely mounted. Check mounting bolts regularly.

Load balance: Ensure the load being driven is balanced and doesn't create sudden torque spikes.

If your current setup involves a redesign to fix alignment issues, it's often worth the investment. But frequently, simply improving maintenance of existing mounting eliminates much of the problem.

Storage and Seasonal Operation

Motors sitting idle face their own challenges, particularly regarding moisture ingress and corrosion.

Before storage:

- Run the motor briefly to warm it (this helps moisture evaporate from internal surfaces)

- Store in a dry location

- Consider coating exposed shaft sections with light oil

- Seal unused connections temporarily

Reactivation:

- Check oil condition before starting

- Rotate the motor shaft manually several times before electrical startup

- Inspect seals for any visible deterioration

Creating a Maintenance Schedule That Actually Works

Theory is fine, but implementation is everything. Here's a maintenance schedule you can actually follow:

Monthly:

- Visual inspection for leaks or damage

- Check for unusual noise or vibration

- Verify operating temperature is within normal range

Quarterly:

- Check lubrication level and condition

- Inspect seals and connections

- Review maintenance log for trends

Annually:

- Oil change (adjust based on operating hours and environment)

- Deep inspection of all connections

- Assessment of bearing condition

Every 2-3 years:

- Professional inspection and testing

- Seal replacement if showing wear

When to Consult a Professional

While these practices handle most maintenance needs, certain situations warrant professional attention:

- Unusual noise or vibration that doesn't correspond to load

- Temperature exceeding 10°C above normal operating range

- Oil condition that doesn't improve with a lubricant change

- Any performance degradation without obvious cause

Small Actions, Significant Results

You don't need to redesign your equipment or replace your motors to achieve dramatically longer lifespan. The strategies outlined here—proper lubrication, contamination control, temperature management, and electrical/mechanical best practices—are the foundation of motor longevity.

Most of these actions require minimal investment and fit seamlessly into standard maintenance routines. Yet collectively, they can extend your motor's productive life by 100% or more. That's not a minor improvement; that's a transformational shift in your operational economics.

At SLW Motor, we're not just interested in selling you a motor—we're interested in ensuring it serves your needs for years to come. If you have specific questions about your motor's maintenance or want to discuss your particular application, our technical team is here to help.

Your DC gear motor is built to last. With proper care, it absolutely will.