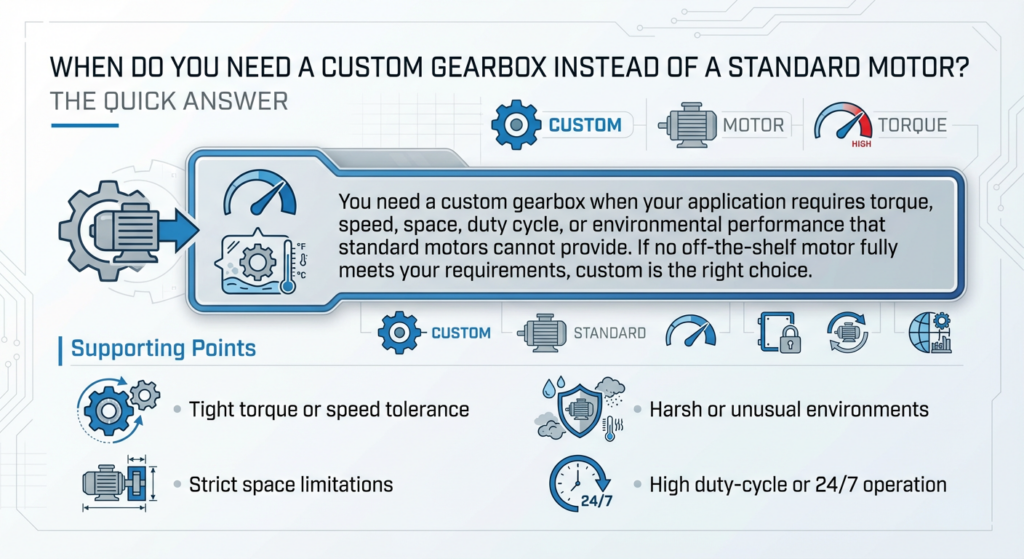

When Do You Need a Custom Gearbox Instead of a Standard Motor?

Let's cut to the chase.

You need a custom gearbox when your application demands specifications that standard motors simply can't deliver.

That means when your required torque, speed, space constraints, duty cycle, or environmental conditions fall outside what off-the-shelf solutions offer. But here's the thing—most applications don't actually need customization.

Before you invest in custom development, ask yourself: Does a standard motor exist that checks all your boxes?

If the answer is no, you've found your answer. Custom is the way to go.

Now, let me walk you through everything you need to know to make this decision with confidence.

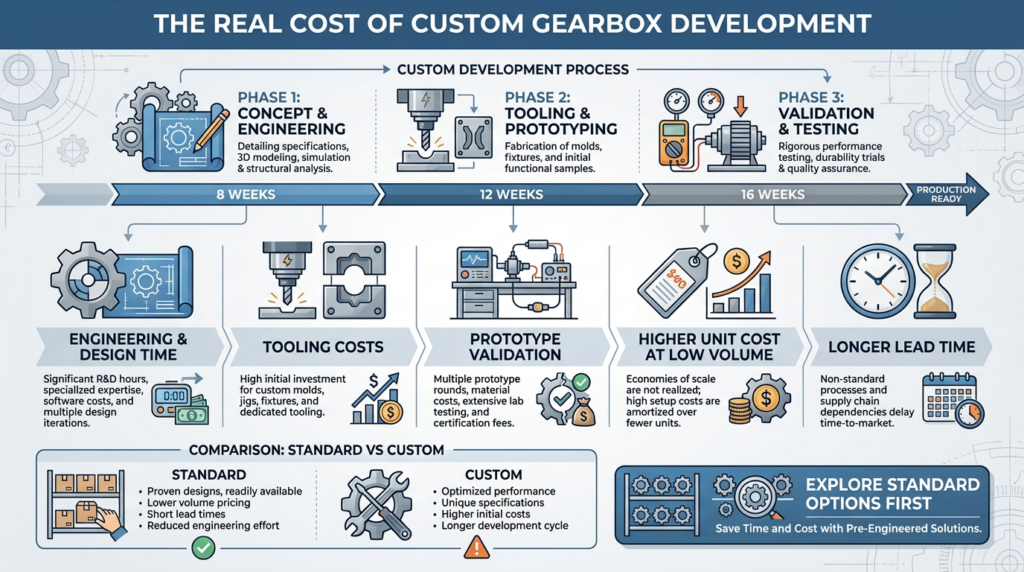

Understanding the Real Cost of Customization

I'll be honest with you—going custom isn't cheap or quick. Custom gearbox development typically adds 8-16 weeks to your timeline and significantly increases your unit costs, especially in low-volume production.

There's engineering time, prototyping, testing, and iteration. So before you decide custom is necessary, you need to understand what you're actually signing up for.

Here's what makes custom development expensive:

- Engineering and design time: Someone needs to calculate gear ratios, simulate performance, and validate your design

- Tooling costs: Custom gears and housings need custom tooling that you'll pay for upfront

- Prototype validation: Testing to ensure it actually works in your application

- Lower unit costs: Until you hit higher volumes, your per-unit price will be higher than standard solutions

- Longer lead times: Custom products take time; there's no "off the shelf" to grab

So here's my genuine advice: exhaust your standard options first.

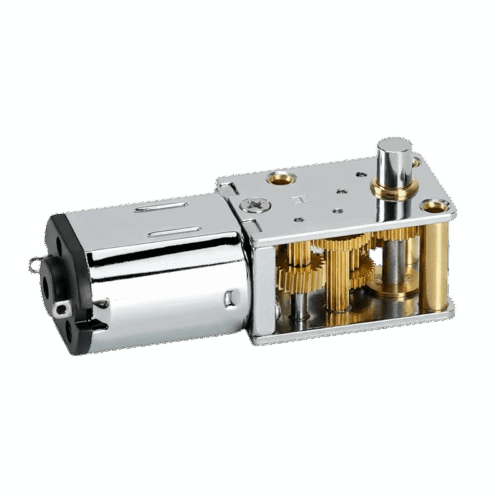

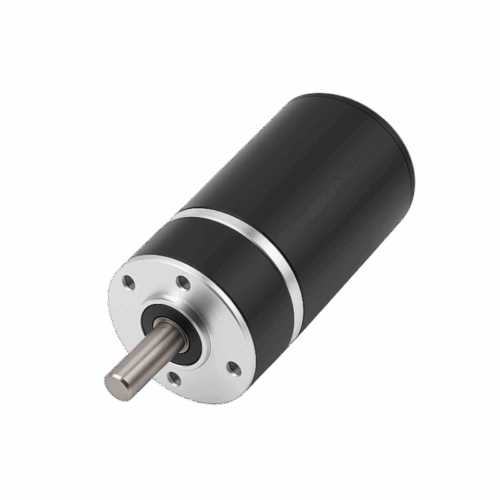

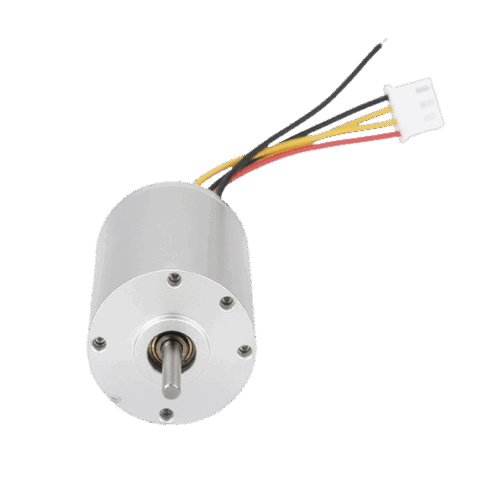

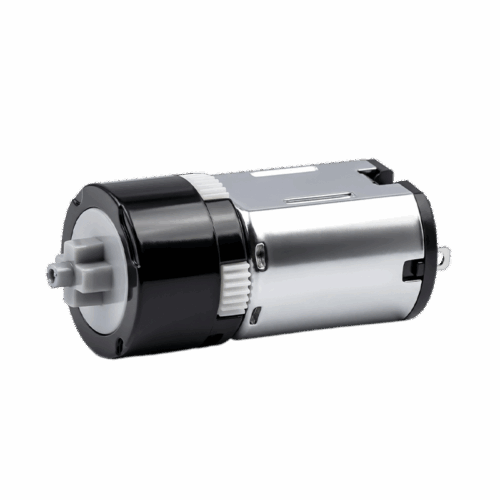

View our Standard DC Motors & Gearboxes.

We carry dozens of DC motor and gearbox combinations. Many customers think they need custom when a standard unit with different gear ratios would solve their problem perfectly.

When Standard Motors Fail You

Let me break down the specific situations where you need custom development:

1. Torque Requirements That Don't Fit Standard Ratios

Standard gearboxes come in common reduction ratios: 4:1, 8:1, 16:1, 32:1, 50:1, and similar increments. Here's the problem—your application might need 27:1 or 43:1 or 58:1.

Let me give you a real example: A client came to us needing a motor-gearbox combo that would produce exactly 15 Nm of torque at 120 RPM from a 12V DC source. We looked at our standard catalog. Our closest option was a 16:1 reduction that produced 16.2 Nm at 125 RPM—close, but not close enough for their precision requirement.

Why did this matter for them?

- Their conveyor speed needed to be exact

- Overshooting the torque would cause product damage

- Undershooting wouldn't turn the load

For this situation, custom was genuinely necessary. We designed a 15.3:1 ratio gearbox that hit their specification exactly.

Ask yourself: Does your application have tight torque or speed tolerances? If yes, custom might be necessary. If you have ±5% tolerance? Standard probably works.

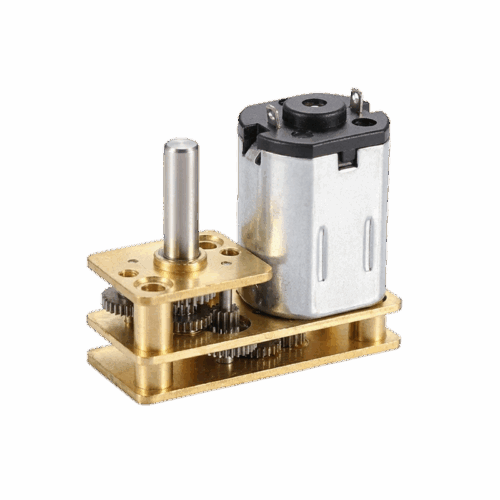

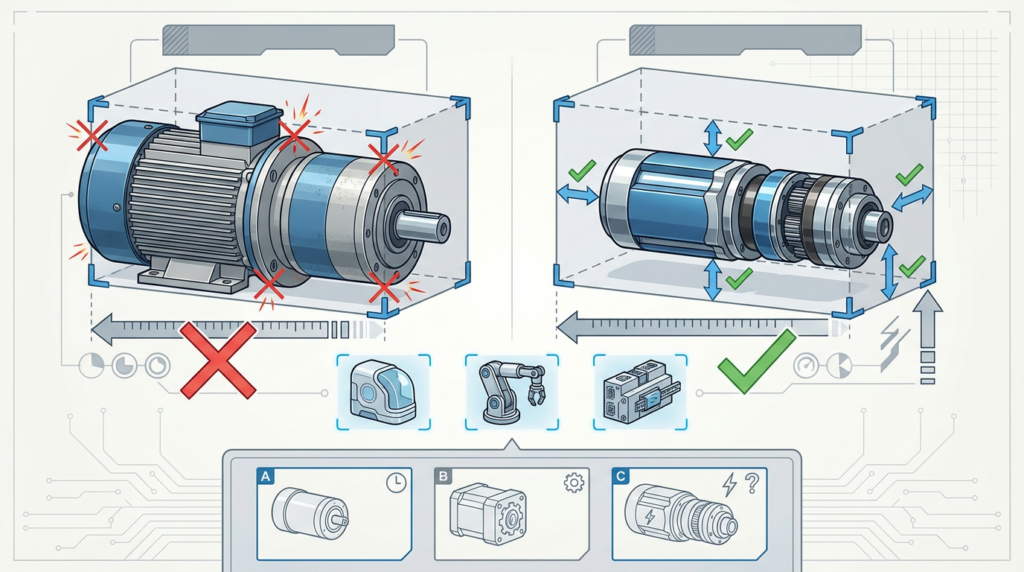

2. Space Constraints That Standard Motors Can't Fit

This is incredibly common, especially in medical devices, robotics, and automated machinery.

Standard motors and gearboxes are designed for "normal" applications. They have standard housing diameters, standard lengths, standard mounting patterns. But what if your available space is 35mm diameter by 60mm length? Or you need a motor that fits into a 40mm x 40mm x 50mm cavity?

Here's where custom solutions shine:

We've designed coreless DC motors paired with custom flat-profile gearboxes for surgical robotics applications. The standard motor-gearbox combo was too large. Custom development shaved 20mm off the length and 8mm off the diameter—exactly what they needed.

If space is tight, you might have multiple options:

- Use a smaller standard motor with higher reduction

- Use a larger standard motor with lower reduction

- Actually go custom

Sometimes option 1 or 2 works fine. But if your space is truly constrained and none of the dimensional combinations work, custom is the answer.

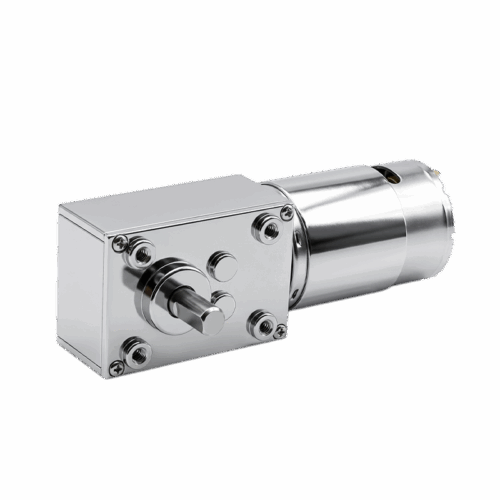

3. Unusual Environmental Demands

Standard motors are built for standard conditions: room temperature, normal humidity, occasional use.

But what if you need:

- Operation in extreme temperatures (below 0°C or above 80°C consistently)

- High humidity or washdown environments (medical, food processing, automotive)

- Radiation-resistant components (medical imaging equipment)

- Explosion-proof or intrinsically safe ratings (chemical plants, oil rigs)

- Sealed against specific contaminants (dust, corrosive chemicals, saltwater)

Standard motors can handle many environments reasonably well, but when you need something beyond "reasonable," you need custom.

Example: We worked with a client in the agricultural equipment space who needed a motor-gearbox that could withstand direct pesticide exposure. Standard sealed motors would eventually degrade. We custom-designed a gearbox with specialty coatings and a sealed housing using specific materials that resist chemical breakdown. It wasn't a different ratio—it was the same 16:1 gearbox—but custom materials made it work where standard couldn't.

4. High-Duty-Cycle Operations

Standard motors are rated for specific duty cycles. A brushed DC motor might be rated for 40% duty cycle (4 hours on, 6 hours off), while a brushless alternative handles 100% continuous duty.

But what if your application needs something different? What if you need:

- Intermittent high-torque peaks (suddenly spinning something very heavy repeatedly)

- Extended high-speed operation (standard gearboxes have limits on output speed)

- Rapid thermal cycling (heating and cooling repeatedly)

Here's the real situation: Standard gearboxes are designed with assumptions about how you'll use them. They have bearing sizes, lubricant types, and thermal management built for "typical" duty. When your duty cycle is atypical, you risk premature failure.

I've seen customers try to push standard motors beyond their ratings. They work—for a while. Then you get warranty returns, field failures, and angry customers. Custom development ensures your motor-gearbox system is engineered specifically for how you'll actually use it.

5. Multiple Functions in One Unit

Here's a sneaky one that catches people off guard.

What if you need a motor-gearbox that also functions as:

- A brake mechanism (holding the output when unpowered)

- An encoder feedback system (precise position tracking)

- Multiple output shafts (driving two things simultaneously)

- Integrated clutch functionality

Standard motors are, well, standard. They do one thing. When you need integrated functionality beyond "motor + gearbox," custom development becomes necessary.

Example: Medical bed applications often need a motor-gearbox with integrated mechanical brakes that hold position when powered off. Standard solutions exist, but they're combinations of separate components. Custom integration can achieve this in less space with better reliability.

Do You Actually Need Custom?

Answer these questions honestly:

Question 1: Can you describe your exact requirements?

- Torque needed?

- Speed needed?

- Duty cycle?

- Environmental conditions?

- Space limitations?

- Any special functions?

If you can't answer these clearly, you're not ready for custom. Start there.

Question 2: Have you looked at standard options?

- Do standard ratios work?

- Is the physical size acceptable?

- Will standard sealing/materials survive your environment?

- Is the rated duty cycle sufficient?

If all answers are yes, standard is your answer. Save your money.

Question 3: Is there a single standard solution that's "close enough"?

- If a standard motor gets you 90% of the way there, and the compromise is acceptable, stick with standard

- Custom is justified when standard leaves you with significant compromises across multiple parameters

Question 4: Is the volume high enough to justify the custom cost?

This is crucial. Custom gearbox development makes sense at certain volumes:

- 500+ units annually: Custom development cost is easily justified

- 100-500 units annually: Custom is borderline economical; consider carefully

- Under 100 units annually: Custom is expensive per unit; explore if standard with workarounds is possible

Standard vs Custom

| Category | Standard Motor / Gearbox | Custom Motor / Gearbox |

|---|---|---|

| Cost | Lowest upfront cost; ideal for most applications | High engineering + tooling cost; expensive for low volumes |

| Lead Time | Immediate availability; fast delivery | Long development cycle (8–16+ weeks) |

| Performance Fit | Works well if requirements fall within common ranges | Tailored exactly to torque, speed, duty cycle, environment |

| Available Gear Ratios | Limited to fixed ratios (4:1, 8:1, 16:1, etc.) | Any ratio needed, including 15.3:1, 27:1, 43:1… |

| Size & Space Constraints | Standard dimensions; may not fit tight enclosures | Fully optimized for limited installation space |

| Environmental Resistance | Suitable for general conditions | Custom materials, sealing, coatings for extreme environments |

| Duty Cycle | Rated for typical operating conditions | Designed for continuous load, heavy peaks, or thermal cycling |

| Function Integration | Motor + gear only | Optional brake, encoder, multi-shaft, clutch, or hybrid assemblies |

| Risk Level | Very low (proven off-the-shelf products) | Higher (requires testing and validation) |

| Best For | 80–90% of applications; fast and economical | High-precision, space-limited, environmental, or specialized needs |

Real-World Scenarios

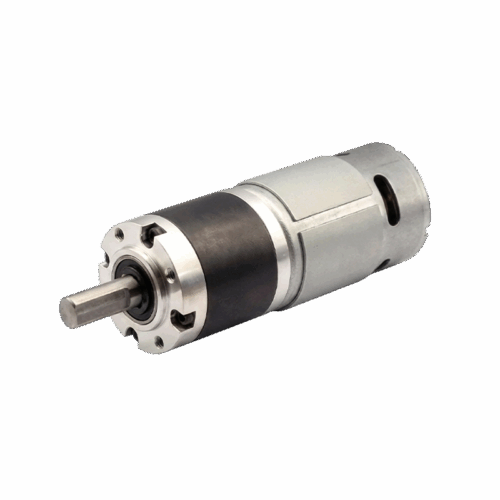

Scenario 1: Robotics Startup

Need: Small motor driving a robotic arm, 5 Nm at 60 RPM, 40mm x 80mm envelope, operating room environment

Standard option? Yes—our brushless DC motor with sealed 8:1 spur gearbox fits perfectly

Decision: Standard. Good fit, faster delivery, lower cost.

Scenario 2: Medical Pump Manufacturer

Need: Precise constant-speed output (±1%), 8 Nm at exactly 45 RPM, encoder feedback, temperature range 5-40°C

Standard option? Closest is 16:1 ratio (50 RPM), could use lower voltage for 45 RPM but loses precision

Decision: Custom. The speed precision and encoder integration justify custom development.

Scenario 3: Industrial Automation

Need: Motor for conveyor belt, 20 Nm at 100 RPM, 24/7 operation, standard industrial enclosure

Standard option? Yes—brushless DC motor with 5:1 gearbox, rated for continuous duty

Decision: Standard. Perfect fit for duty cycle and environment.

Scenario 4: Outdoor Agricultural Equipment

Need: Motor driving mixing mechanism, 12 Nm at 80 RPM, operates in -20°C to 50°C, heavy dust/mud environment

Standard option? Motor exists, but standard sealing won't handle the extreme temperature range and contaminant exposure

Decision: Custom. Environmental demands exceed standard capabilities.

Working with Us: Making the Custom Decision

Here's how we approach this at SLW:

Step 1: Requirements Definition

You tell us exactly what you need. We ask clarifying questions. Lots of them. This is free and takes 30-60 minutes.

Step 2: Standard Solutions Assessment

We pull options from our catalog and show you what's available. This includes trade-offs. Sometimes we surprise customers—standard solutions they didn't know existed that work better than expected.

Step 3: Custom Feasibility

If standard doesn't work, we define custom scope:

- What's being customized? (ratio, housing, materials, integration, all of above?)

- Timeline

- Cost estimate

- Volume requirements for economical production

Step 4: You Decide

You now have enough information to make a smart choice.

Custom gearboxes are powerful tools for solving problems standard motors can't handle. But they're also expensive and slow. The fact that customization is possible doesn't mean it's necessary for your application.

Start with an assessment of your requirements. Compare against standard solutions. Look at trade-offs. Only move to custom when you can't find a standard solution that works.

When you do need custom? We're here. We've designed custom gearboxes for applications from surgical robots to industrial pumps. We'll engineer it right, test it thoroughly, and deliver it on time.

But first, let's make sure you actually need it.

Reach out with your requirements. We'll help you figure out if you're a standard motor customer or a custom gearbox customer. Either way, we've got the right solution.

How can we help? Contact our engineering team with your motor specifications. We'll review your application and recommend whether standard solutions fit your needs or if custom development is your best path forward.