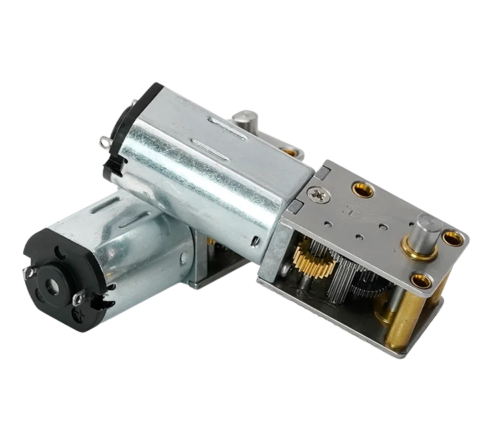

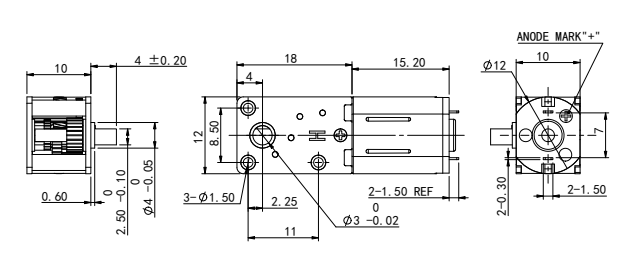

12mm Brushed DC Motor With 90 Degree Shaft Worm Gearbox

The 12mm micro bushed motor with 90-degree shaft worm gearbox is designed for space-constrained layouts, enabling right-angle power transmission in compact electromechanical assemblies.

This model is centered on layout flexibility and directional output control. The 90-degree worm gearbox allows designers to route motion efficiently where inline configurations are impractical.

| Reduction ratio | No-Load | Rated Load | Stall | ||||||

| Rated Voltage (V) | Speed (RPM±10%) | Current (A) | Speed (RPM±10%) | Current (A) | Torque (Kg.cm) | Power (W) | Torque (Kg.cm) | Current (A) | |

| 18 | 12 | 1055 | 21 | 9000 | 65 | 16 | 0.80 | 110 | 340 |

| 42 | 12 | 452 | 21 | 385 | 65 | 38 | 0.80 | 257 | 340 |

| 63 | 12 | 301 | 21 | 257 | 65 | 57 | 0.80 | 385 | 340 |

| 80 | 12 | 237 | 21 | 202 | 65 | 72 | 0.80 | 490 | 340 |

| 102 | 12 | 186 | 21 | 158 | 65 | 92 | 0.80 | 624 | 340 |

| 105 | 12 | 180 | 21 | 154 | 65 | 95 | 0.80 | 642 | 340 |

| 115 | 12 | 165 | 21 | 140 | 65 | 104 | 0.80 | 703 | 340 |

| 121 | 12 | 157 | 21 | 103 | 65 | 109 | 0.80 | 740 | 340 |

| 127 | 12 | 149 | 21 | 108 | 65 | 114 | 0.80 | 777 | 340 |

| 157 | 12 | 121 | 21 | 103 | 65 | 141 | 0.80 | 960 | 340 |

| 244 | 12 | 77 | 21 | 66 | 65 | 220 | 0.80 | 1493 | 340 |

| 298 | 12 | 63 | 21 | 54 | 65 | 268 | 0.80 | 1823 | 340 |

| 302 | 12 | 62 | 21 | 53 | 65 | 272 | 0.80 | 1848 | 340 |

| 311 | 12 | 61 | 21 | 52 | 65 | 280 | 0.80 | 1903 | 340 |

| 345 | 12 | 55 | 21 | 46 | 65 | 310 | 0.80 | 2111 | 340 |

| 604 | 12 | 31 | 21 | 26 | 65 | 543 | 0.80 | 3696 | 340 |

| 898 | 12 | 21 | 21 | 18 | 65 | 808 | 0.80 | 5459 | 340 |

| 992 | 12 | 19 | 21 | 16 | 65 | 992 | 0.80 | 6071 | 340 |

| 1032 | 12 | 18 | 21 | 15 | 65 | 928 | 0.80 | 6315 | 340 |

| 1576 | 12 | 12 | 21 | 10 | 65 | 1418 | 0.80 | 9645 | 340 |

For additional customization or reference configurations, please feel free to contact us.

For detailed selection guidance or project-specific requirements, please contact our team for further support.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.