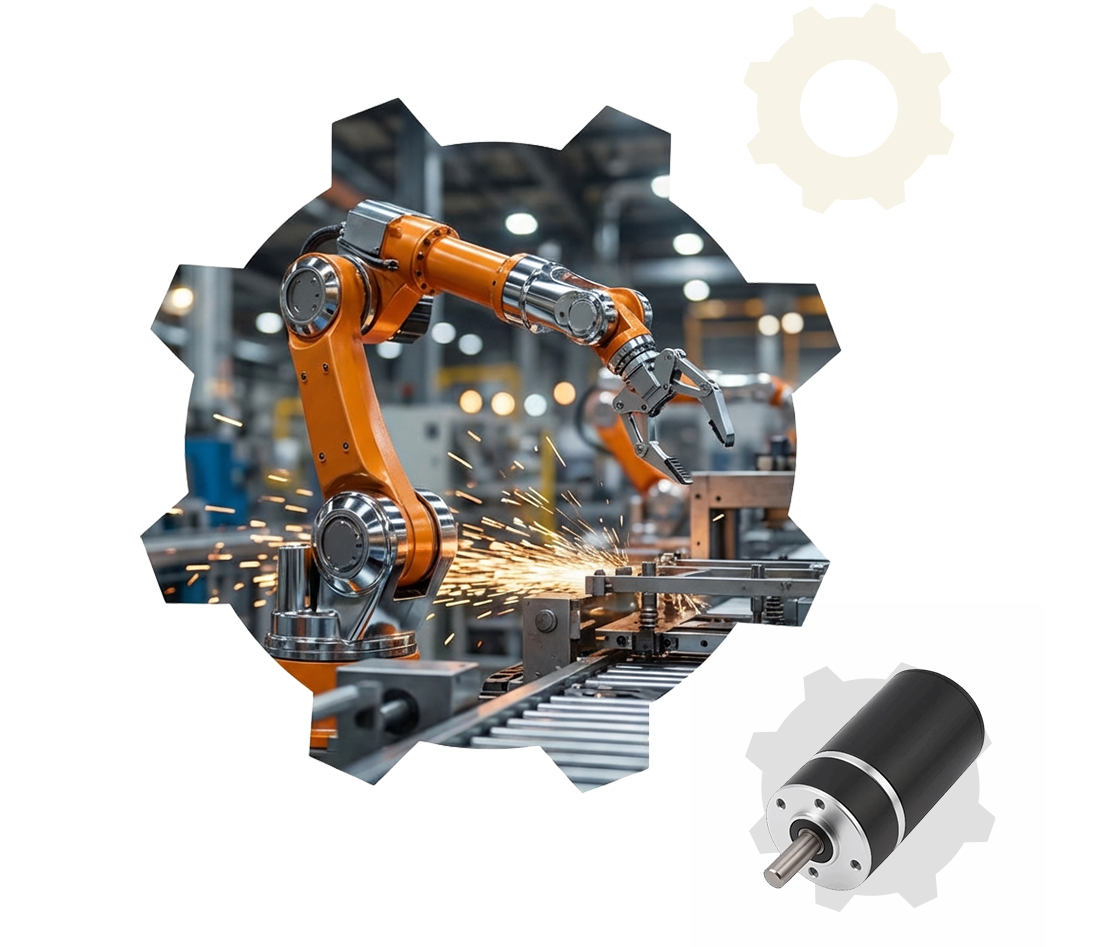

Robotics and Automation

Robotics and automation demand compact, high-precision, and reliable motion components. Our miniature motors and gear motors deliver the accuracy, torque stability, and durability required for modern robotic systems.

Small form factors with powerful output, ideal for space-constrained robotic designs without sacrificing performance.

Low-wear materials, optimized gear structures, and efficient thermal performance ensure consistent operation under continuous or high-duty cycles.

Voltage, speed, torque, shaft types, and gear ratios can be tailored for unique robotic motion profiles and integration requirements.

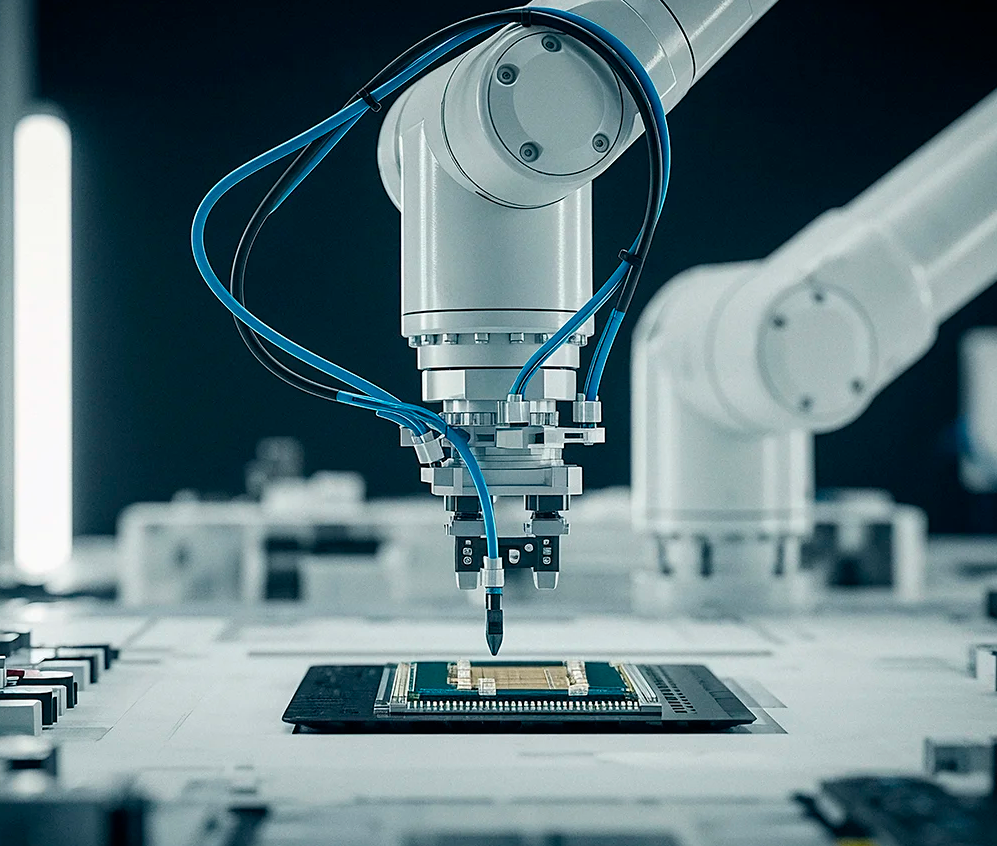

Designed for stable, repeatable motion control, ensuring smooth actuation for robotic joints, grippers, and sensing mechanisms.

Our motors power a wide range of automation and robotic functions where precise, compact, and smooth motion is essential.

Robotic joints and actuators require carefully matched torque–speed curves to ensure smooth start-up, stable movement, and vibration control.

Depending on the system, stepper, coreless, or brushless motors are selected for accuracy, low noise, or high responsiveness.

Low-backlash spur or planetary gearboxes are crucial for positioning accuracy, especially in robotic arms and grippers.

Lightweight motors help reduce energy consumption and increase mobility, especially in humanoid and service robots.

Continuous operation in automation lines requires motors designed for high-duty cycles with proper heat dissipation.

Applications involving sensors, cameras, or human interaction require low-noise and low-vibration motor designs to ensure smooth user experience and measurement stability.

English

Japanese

Korean

Tell us about your project or application, and our team will get back to you with technical support, product recommendations, or a customized motor solution.