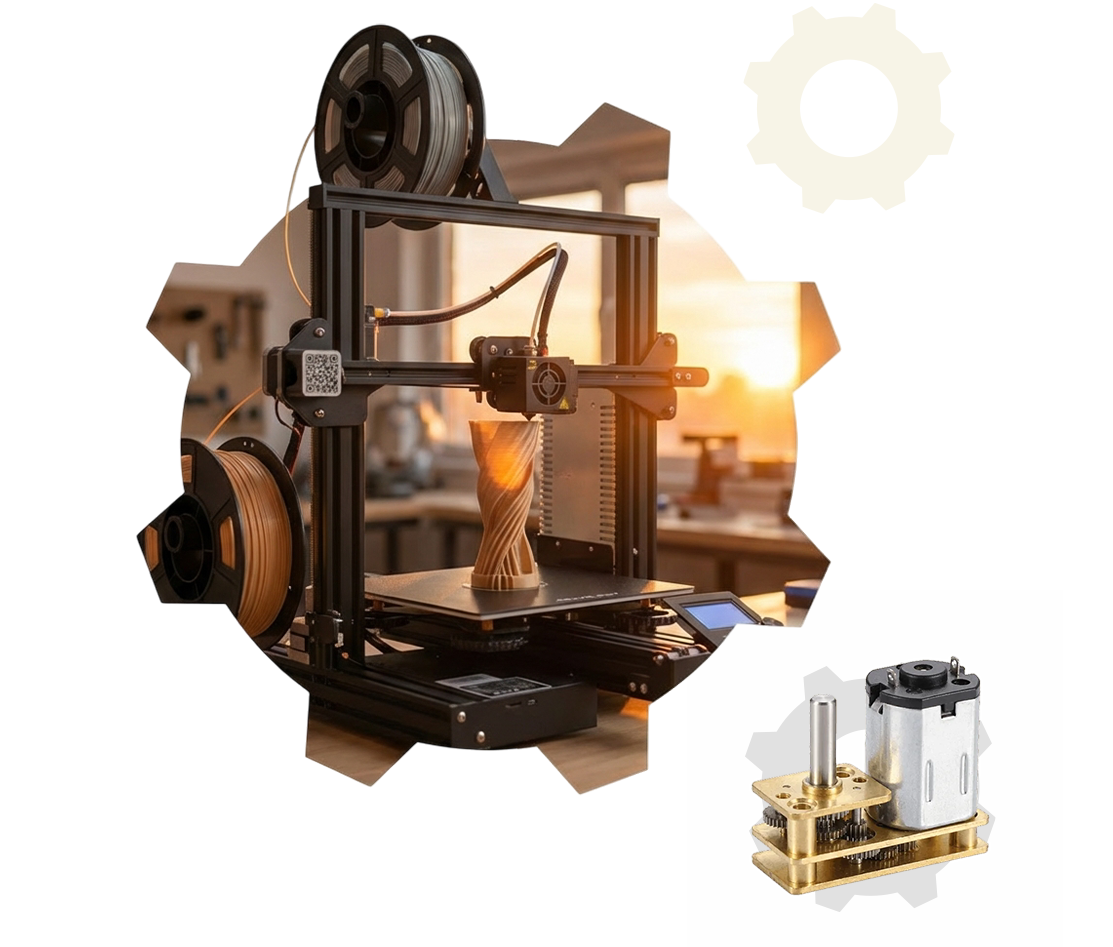

3D Printing & CNC Equipment

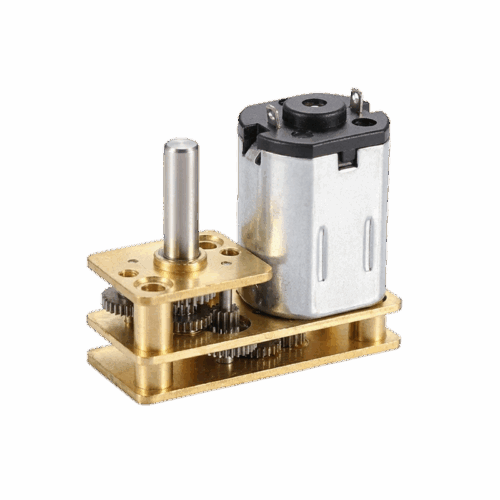

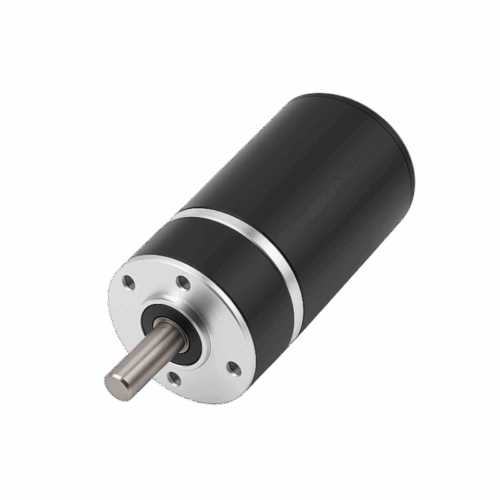

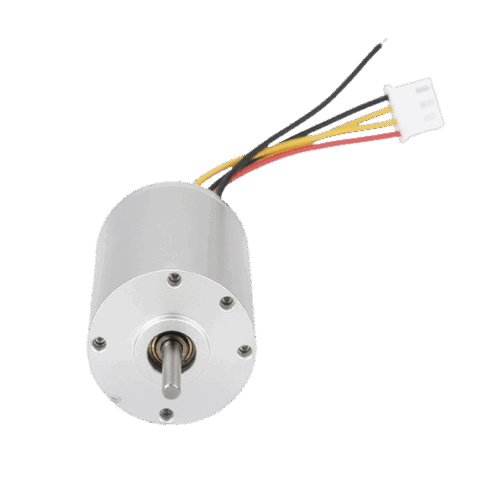

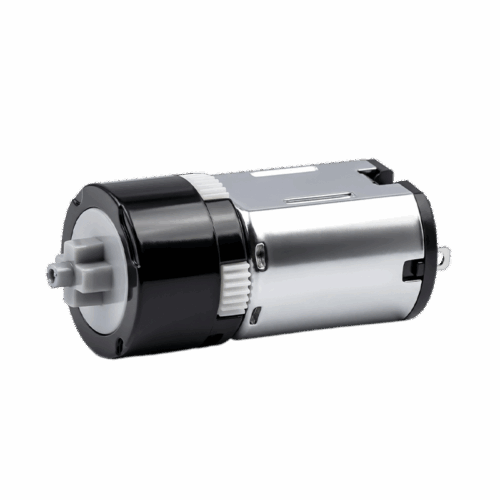

3D printers and CNC machines rely on precise, stable, and highly controllable motion systems. Our miniature motors and gear motors deliver the accuracy, torque consistency, and durability needed for reliable multi-axis movement, extrusion control, and fine positioning under continuous operation.